Top Suppliers of Flanged Ball Valves for Industrial Applications

Understanding Ball Valve Flange Suppliers

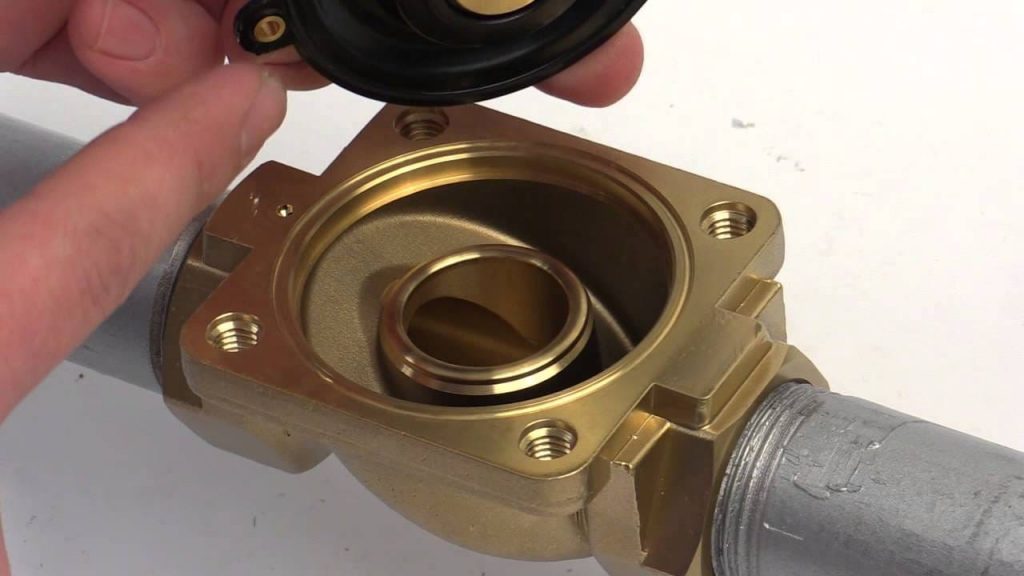

Ball valves with flanges are critical components in various industrial applications, providing reliable flow control in piping systems. Their durability, efficiency, and ease of operation make them a popular choice among engineers and contractors. In the realm of fluid control, the selection of the right ball valve flange supplier can significantly impact the functionality and longevity of your systems. This article delves into the importance of choosing the right supplier, key factors to consider, and a brief overview of the market.

Importance of Choosing the Right Supplier

Selecting a reputable ball valve flange supplier is essential for several reasons. Firstly, quality plays a crucial role in the performance of ball valves. High-quality valves are less likely to fail, resulting in reduced downtime and maintenance costs. A reliable supplier ensures that the products meet international standards and are manufactured from high-grade materials, enhancing their lifespan in challenging environments.

Secondly, a good supplier offers a wide range of products catering to various applications. Industries such as oil and gas, water treatment, and chemical processing all have unique requirements. A diverse inventory means that customers can find valves that fit their specific needs without compromising on quality or performance.

Lastly, after-sales support is a significant factor in supplier selection. A reputable supplier should provide technical support, warranties, and an efficient return policy. When issues arise, having a responsive supplier can make all the difference in maintaining operational efficiency.

Key Factors to Consider When Choosing a Supplier

1. Quality Assurance Look for suppliers that adhere to strict quality control measures and offer certifications such as ISO 9001. Quality assurance guarantees that the products are tested for reliability and performance.

2. Product Range Evaluate the variety of ball valves and flanged options available. Suppliers who provide a wide assortment will likely meet your future needs as well.

ball valve flange suppliers

3. Material Options Different applications require different materials. Suppliers should offer valves made from stainless steel, carbon steel, PVC, and other materials that suit corrosive or high-pressure environments.

4. Pricing and Terms While cost should not be the only factor, it is essential to compare prices from multiple suppliers. Also, consider payment terms, shipping options, and any bulk purchasing discounts.

5. Reputation and Experience Research potential suppliers to gain insights into their market reputation. Reviews, case studies, and testimonials can provide valuable information about their reliability and customer service.

6. Technical Support Ensure the supplier offers technical assistance to help you select the right products for your application. Knowledgeable staff can guide you through the selection process and help troubleshoot any issues.

Overview of the Market

The market for ball valve flange suppliers is diverse, with numerous players ranging from large manufacturers to specialized suppliers. Globalization has allowed suppliers to source materials from various regions, leading to competitive pricing and innovation in manufacturing processes.

Regions such as Asia, Europe, and North America have significant suppliers, each offering unique advantages. Asian suppliers often provide cost-effective options due to lower labor costs, while European manufacturers are known for their high-quality standards. North American suppliers typically emphasize quick delivery times and personalized customer service.

In conclusion, the selection of a ball valve flange supplier should be a well-considered decision that impacts the efficiency and reliability of your piping systems. By focusing on quality, product diversity, reputation, and customer support, you can ensure that your operations run smoothly, ultimately enhancing productivity and reducing costs. Whether you are a seasoned contractor or a new engineer, understanding the significance of choosing the right supplier will set the foundation for successful projects in the future.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025