Jan . 20, 2025 13:05

Back to list

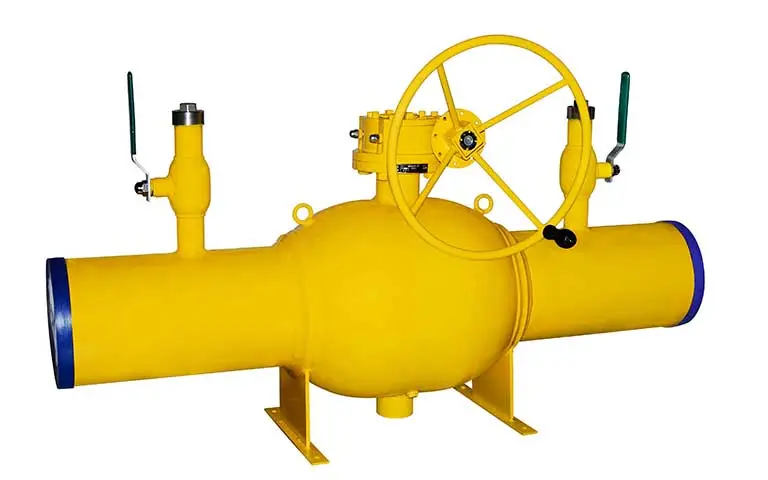

SPF45-10/16 Number Lock Balanced Valve

When it comes to efficiently controlling fluid flow in a wide range of industrial applications, flanged butterfly valves stand out as an indispensable component. Known for their durability, versatility, and cost-effectiveness, these valves have been pivotal in the fluid control industry, carving a niche as reliable and efficient solutions. Let’s delve into the unique advantages and practical applications of flanged butterfly valves, guided by expertise, authoritativeness, and trustworthiness.

User experience is another critical dimension influencing the chosen valve's success. Flanged butterfly valves offer an intuitive, straightforward user interface, simplifying operation even for those with limited technical knowledge. Their ergonomic lever handles or gear-operated actuators allow for precise control, essential in applications where fluid flow needs to be accurately regulated. This user-friendly aspect fosters trust and satisfaction, encouraging repeat business and long-term customer relationships. Real-world experience speaks volumes about the practical benefits of flanged butterfly valves. Many industries report substantial savings and efficiency improvements after replacing aging gate or ball valves with modern butterfly valves. These reports highlight reduced maintenance costs, improved fluid control accuracy, and minimized risk of leakage or valve failure, particularly in high-demand environments such as refineries and power plants. The flanged butterfly valve market continues to evolve, with manufacturers investing in research and development to enhance valve performance and sustainability. Modern innovations include smart valves integrated with sensors and IoT capabilities, enabling remote monitoring and precise control, drastically reducing the need for manual intervention. These technological advancements not only increase operational efficiency but also align with global sustainability goals by reducing energy consumption and minimizing waste. In conclusion, flanged butterfly valves represent a sophisticated blend of engineering expertise, reliability, and user-centric design. Their adaptability across diverse sectors makes them an invaluable asset in both emerging and established industries. By maintaining a steadfast commitment to quality and innovation, manufacturers ensure that flanged butterfly valves remain at the forefront of fluid control technology, embodying a legacy of excellence and trustworthiness. As industry demands evolve, these valves will undoubtedly continue to adapt, meet changing expectations, and cement their status as a cornerstone in fluid management solutions.

User experience is another critical dimension influencing the chosen valve's success. Flanged butterfly valves offer an intuitive, straightforward user interface, simplifying operation even for those with limited technical knowledge. Their ergonomic lever handles or gear-operated actuators allow for precise control, essential in applications where fluid flow needs to be accurately regulated. This user-friendly aspect fosters trust and satisfaction, encouraging repeat business and long-term customer relationships. Real-world experience speaks volumes about the practical benefits of flanged butterfly valves. Many industries report substantial savings and efficiency improvements after replacing aging gate or ball valves with modern butterfly valves. These reports highlight reduced maintenance costs, improved fluid control accuracy, and minimized risk of leakage or valve failure, particularly in high-demand environments such as refineries and power plants. The flanged butterfly valve market continues to evolve, with manufacturers investing in research and development to enhance valve performance and sustainability. Modern innovations include smart valves integrated with sensors and IoT capabilities, enabling remote monitoring and precise control, drastically reducing the need for manual intervention. These technological advancements not only increase operational efficiency but also align with global sustainability goals by reducing energy consumption and minimizing waste. In conclusion, flanged butterfly valves represent a sophisticated blend of engineering expertise, reliability, and user-centric design. Their adaptability across diverse sectors makes them an invaluable asset in both emerging and established industries. By maintaining a steadfast commitment to quality and innovation, manufacturers ensure that flanged butterfly valves remain at the forefront of fluid control technology, embodying a legacy of excellence and trustworthiness. As industry demands evolve, these valves will undoubtedly continue to adapt, meet changing expectations, and cement their status as a cornerstone in fluid management solutions.

Next:

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025