Jan . 23, 2025 05:18

Back to list

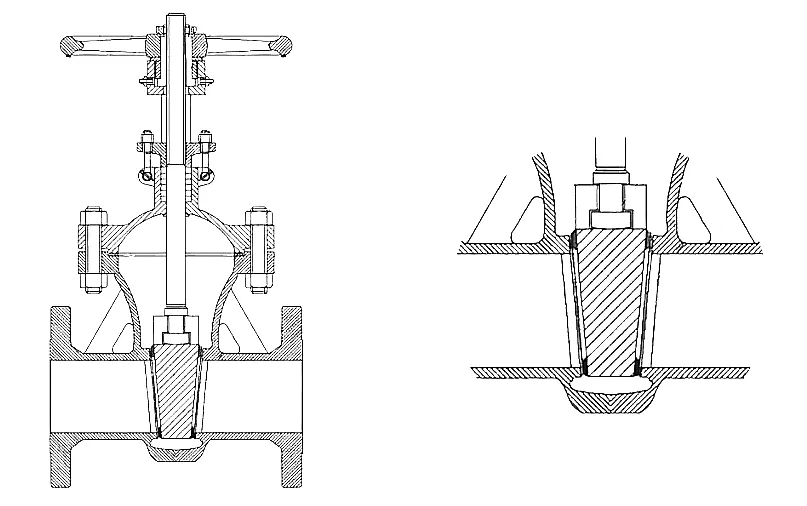

GL41H-16/16Q WCB material Flange Y Type Strainer

In the intricate world of industrial fluid management, the low pressure check valve emerges as an essential component, highly regarded for its capacity to seamlessly manage the flow of liquids and gases, even under minimal pressure conditions. The sophisticated design and functionality of these valves make them indispensable across various industries, including water treatment, HVAC systems, pharmaceuticals, and more. This exploration into low pressure check valves invites a deep dive into their importance, unique features, and the unparalleled advantages they offer to industry professionals who demand efficiency and reliability.

From the perspective of authority and trustworthiness, low pressure check valves are backed by stringent industry standards and certifications. Manufacturers adhering to ISO quality management systems ensure that these valves perform reliably under specified conditions, complying with safety and performance benchmarks that are globally recognized. This adherence is not merely an assurance of quality but a testament to the commitment to safety and operational excellence that reputable manufacturers uphold. In practical terms, the impact of implementing low pressure check valves in industrial systems cannot be overstated. Case studies from water treatment facilities and HVAC systems illustrate significant reductions in energy consumption and maintenance costs, attributed to the valves’ ability to sustain pressure equilibrium while preventing unwarranted backflow. These tangible benefits underscore the practicality and efficiency that these components bring to the table, offering a clear competitive advantage to businesses that prioritize operational excellence. Finally, the expertise surrounding low pressure check valves extends to their long-term durability and minimal maintenance requirements. Designed to resist wear and tear over extended periods, these valves necessitate infrequent inspections and repairs, translating to lower operational downtime and enabling a focus on core business activities. In conclusion, low pressure check valves exemplify a blend of engineering brilliance and practical efficacy, fundamental to industries reliant on precise fluid control. Their expert design, backed by authoritative certifications, underlines a commitment to reliability and efficiency, making them an unequivocal choice for industry leaders seeking innovative solutions to fluid management challenges. As technology evolves and industries continue to demand higher standards of performance, low pressure check valves will undoubtedly remain at the forefront, offering unmatched reliability and operational peace of mind.

From the perspective of authority and trustworthiness, low pressure check valves are backed by stringent industry standards and certifications. Manufacturers adhering to ISO quality management systems ensure that these valves perform reliably under specified conditions, complying with safety and performance benchmarks that are globally recognized. This adherence is not merely an assurance of quality but a testament to the commitment to safety and operational excellence that reputable manufacturers uphold. In practical terms, the impact of implementing low pressure check valves in industrial systems cannot be overstated. Case studies from water treatment facilities and HVAC systems illustrate significant reductions in energy consumption and maintenance costs, attributed to the valves’ ability to sustain pressure equilibrium while preventing unwarranted backflow. These tangible benefits underscore the practicality and efficiency that these components bring to the table, offering a clear competitive advantage to businesses that prioritize operational excellence. Finally, the expertise surrounding low pressure check valves extends to their long-term durability and minimal maintenance requirements. Designed to resist wear and tear over extended periods, these valves necessitate infrequent inspections and repairs, translating to lower operational downtime and enabling a focus on core business activities. In conclusion, low pressure check valves exemplify a blend of engineering brilliance and practical efficacy, fundamental to industries reliant on precise fluid control. Their expert design, backed by authoritative certifications, underlines a commitment to reliability and efficiency, making them an unequivocal choice for industry leaders seeking innovative solutions to fluid management challenges. As technology evolves and industries continue to demand higher standards of performance, low pressure check valves will undoubtedly remain at the forefront, offering unmatched reliability and operational peace of mind.

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025