Flanged Steam Trap Solutions for Efficient Temperature and Pressure Management

Understanding Flanged Type Steam Traps Functionality and Applications

In industrial processes, steam is an essential medium for various operations, from heating and sterilization to power generation. However, the effective management of steam systems is critical to ensure operational efficiency and prevent energy loss. One key component in this system is the steam trap, specifically the flanged type steam trap. This article delves into the functionality and applications of flanged type steam traps, exploring their importance in maintaining steam system efficiency.

What is a Steam Trap?

A steam trap is a mechanical device used in steam systems to discharge condensate, air, and other non-condensable gases while preventing the escape of steam. By efficiently managing these elements, steam traps play a crucial role in ensuring that the steam system operates at optimal efficiency.

The Flanged Type Steam Trap

Flanged type steam traps are a specific configuration of steam traps that are designed with flanged connections. This design allows the trap to be securely fastened to pipes, facilitating installation and maintenance. Flanged steam traps are typically constructed from robust materials such as cast iron or stainless steel, making them suitable for high-pressure and high-temperature applications.

Functionality of Flanged Type Steam Traps

The primary function of a flanged steam trap is to provide effective drainage of condensate while maintaining steam in the system.

1. Condensate Discharge As steam travels through pipes, it naturally condenses when it loses heat. Flanged type steam traps are designed to automatically remove this condensate to prevent water accumulation, which can lead to waterhammer, corrosion, and reduced heating efficiency.

2. Air Removal Along with condensate, air and other non-condensable gases can also enter the steam system. Flanged steam traps help in venting these gases efficiently, ensuring that the steam is effective in its heat transfer capabilities.

3. Preventing Steam Loss One of the most critical roles of any steam trap is to prevent steam from escaping the system. Flanged type traps achieve this by using mechanisms such as float and thermostatic controls, which operate to keep the trap closed until the condensate needs to be discharged.

Types of Flanged Type Steam Traps

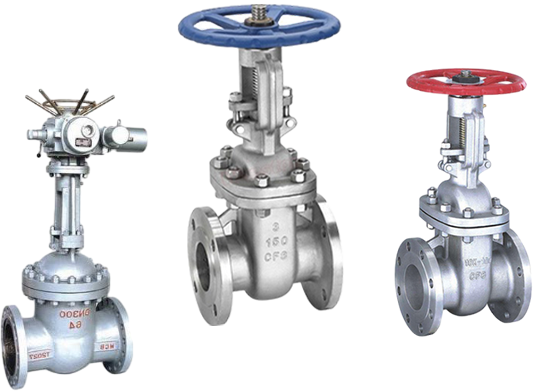

steam trap flanged type

Flanged steam traps come in various types, each designed for specific applications

- Floating Ball Traps Utilizes a floating mechanism that rises and falls with the water level, opening and closing the discharge port as required. - Thermodynamic Traps Employs the principles of thermodynamics to open and close automatically based on the temperature and pressure of the steam and condensate.

- Bimetallic Traps Uses two dissimilar metals that expand at different rates to create movement that controls the trap's valve.

Each of these designs provides unique advantages, making flanged steam traps versatile components in steam management.

Applications of Flanged Type Steam Traps

Flanged type steam traps are employed across various industries due to their reliability and robustness. Their applications include

- Food and Beverage Industry Maintaining consistent temperature control in pasteurization and cooking processes.

- Pharmaceuticals Ensuring sterilization processes are effective without the risk of steam loss.

- Power Generation Managing steam systems in turbines and heat exchangers for maximum efficiency.

- HVAC Systems Regulating steam heating in large buildings.

Conclusion

The efficient operation of steam systems is vital for numerous industrial applications, and flanged type steam traps are integral to this process. By providing reliable condensate discharge, air removal, and preventing steam loss, these devices enhance the efficiency and longevity of steam systems. Their robust design and variety of types make them suitable for a wide range of high-demand applications. For industries seeking to optimize their steam systems, investing in quality flanged type steam traps is a step towards achieving operational excellence and reducing energy costs.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025