Precision Control with 8mm Needle Valve for Fluid Regulation and Flow Management

The 8mm Needle Valve A Vital Component in Fluid Control Systems

The 8mm needle valve is an essential instrument in various fluid control applications, widely used in industries such as oil and gas, pharmaceuticals, and manufacturing. This valve type allows for precise regulation of fluid flow, making it an indispensable component in any setup that requires careful management of liquid or gas movement.

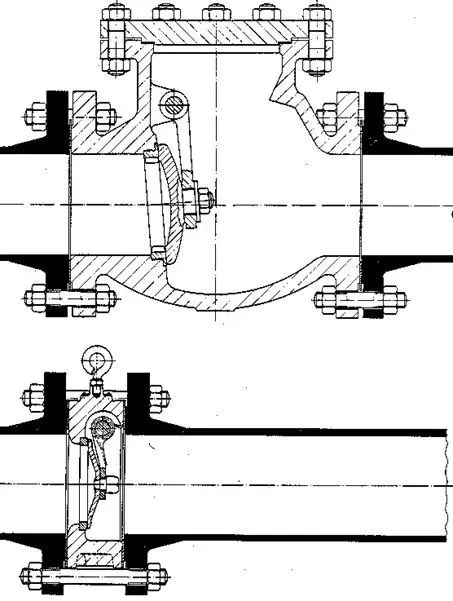

Design and Functionality

The needle valve is characterized by its slender, conical plunger, or needle, which fits into a seat. The 8mm designation refers to its diameter; this specific sizing is crucial for applications that require fine adjustments in flow rates. When the valve is turned, the needle moves closer to or farther away from the seat, thereby controlling the flow of fluid. This design allows for a higher degree of control compared to other types of valves, such as ball or gate valves, which can only be fully open or fully closed.

One of the primary advantages of the 8mm needle valve is its ability to provide incremental changes in flow rates. This capability is particularly useful in processes that require precise measurement and adjustments, such as dosing liquids in chemical reactions or managing the pressure in hydraulic systems.

Applications

The applications of the 8mm needle valve are vast and varied

. In the oil and gas industry, these valves are often used in drilling operations, where they help regulate the flow of drilling fluids and prevent backflow, which can be hazardous. In the pharmaceutical sector, needle valves ensure that the right amount of active ingredients is delivered during the manufacturing process, maintaining the accuracy and efficacy of medications.In the field of manufacturing, needle valves play a crucial role in pneumatic and hydraulic systems. They are employed to control air or fluid pressure in machinery, ensuring smooth operation and preventing potential mechanical failures. The precision control offered by 8mm needle valves is ideal for applications where even minor fluctuations in flow can lead to significant problems.

8mm needle valve

Advantages of Using an 8mm Needle Valve

The key benefits of utilizing an 8mm needle valve include

1. Precision Control As mentioned, the primary feature of needle valves is their ability to provide fine control over fluid flow. This is vital in many industrial applications where accuracy is paramount. 2. Durability Needle valves are often constructed from robust materials such as stainless steel or brass, making them suitable for high-pressure and high-temperature environments. This durability extends the lifespan of the valve, reducing the need for frequent replacements.

3. Versatility The 8mm size makes these valves suitable for a variety of applications, whether in small-scale laboratory setups or large industrial systems. Their adaptability makes them a common choice across many sectors.

4. Ease of Maintenance Regular maintenance of needle valves is relatively straightforward. Proper care can enhance their performance and longevity, ensuring they continue to operate efficiently over time.

Conclusion

In summary, the 8mm needle valve is a crucial component in fluid control systems, offering precise flow regulation and versatility across multiple industries. Its design allows for fine adjustments, contributing to the efficiency and safety of various processes. As industries continue to evolve with technology, the importance of reliable components like the 8mm needle valve will remain integral to achieving operational excellence. Investing in high-quality needle valves can lead to significant improvements in both performance and reliability in any application requiring fluid management.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025