Pricing Information for 3 Inch Gate Valves in Today's Market

Understanding the Pricing of 3% Gate Valves A Comprehensive Overview

Gate valves are essential components in various industrial applications, serving a crucial role in the control and regulation of fluid flow. Among the different types of gate valves, the 3% gate valve has gained prominence due to its reliability and efficiency. Understanding its pricing is vital for engineers, procurement managers, and project planners. In this article, we will explore the factors influencing the prices of 3% gate valves and provide an overview of their market dynamics.

What is a 3% Gate Valve?

A 3% gate valve is typically characterized by its ability to provide minimal resistance to fluid flow when fully opened, which makes it an ideal choice for applications requiring quick and efficient isolation of flow. The term 3% generally refers to the allowable leakage rate or the tolerance level associated with the valve's design. This feature is critical for applications where leakage needs to be minimized, such as in water treatment plants, chemical processing, and oil and gas industries.

Key Factors Influencing Pricing

1. Material Composition The materials used in manufacturing gate valves significantly affect their prices. Common materials include cast iron, stainless steel, bronze, and various alloys. For instance, stainless steel valves tend to be more expensive due to their corrosion resistance and durability, making them suitable for harsh environments.

2. Size and Specifications The size of the valve plays a crucial role in determining its cost. Larger valves require more materials and complex manufacturing processes, which can increase the price. Additionally, specific technical specifications, such as pressure ratings and connection types (flanged, threaded, etc.), influence pricing.

3. Manufacturing Process The method of production—whether it is a forged, cast, or machined valve—also affects pricing. Forged valves are often stronger and more reliable, typically coming at a higher price point compared to cast valves. The complexity of the design and the level of automation in the manufacturing process can also lead to variations in cost.

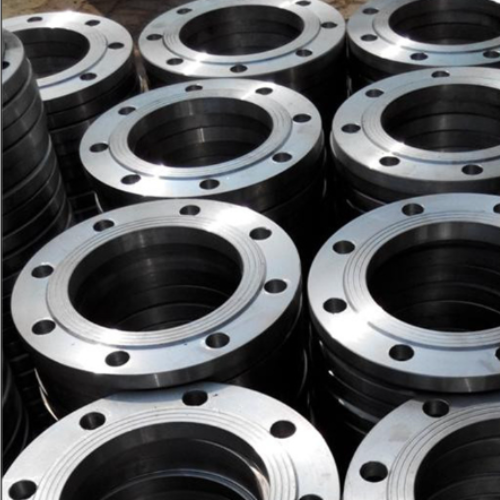

3 gate valve price

4. Brand and Quality Standards Brand reputation can significantly impact pricing. Well-established manufacturers with a history of producing high-quality products may charge more for their valves compared to lesser-known brands. Moreover, compliance with international quality standards (like API, ASME, or DIN) can elevate prices due to the rigorous testing and certifications required.

5. Market Demand and Supply The overall market conditions play a significant role in determining the price of 3% gate valves. During times of high demand, such as when major infrastructure projects are underway, prices may surge. Conversely, during periods of low demand, prices may stabilize or decrease.

6. Geographical Factors Regional variations in costs can also impact valve pricing. For instance, labor costs, shipping fees, and local manufacturing capabilities contribute to the final price. Import taxes and tariffs can make imported valves significantly more expensive than domestically produced counterparts.

Average Price Ranges

Given these variables, the pricing for 3% gate valves can vary widely. On average, small sizes (1-2 inches) can range from $50 to $150, while medium sizes (3-6 inches) might cost between $150 to $500. Larger valves (8 inches and above) can exceed $500, depending on their material and specification complexities.

Conclusion

Understanding the pricing of 3% gate valves is crucial for making informed purchasing decisions. By considering the factors outlined above—material composition, size, manufacturing processes, brand reputation, market dynamics, and geographical influences—buyers can better navigate the complexities of valve procurement. As industries continue to evolve and demand for efficient flow control solutions grows, staying informed about the market trends and price fluctuations will enable stakeholders to optimize their purchasing strategies and ensure the success of their projects.

-

Top-Quality Pipe and Pipe Fittings for Reliable Fluid SystemsNewsAug.28,2025

-

Reliable Slip On Flange Manufacturer for Industrial ExcellenceNewsAug.28,2025

-

Premium Rubber Expansion Joints for Piping SystemsNewsAug.28,2025

-

Premium Electric Actuators for Smart Automation SolutionsNewsAug.28,2025

-

Innovative Flange Solutions for Modern Plumbing NeedsNewsAug.28,2025

-

High-Performance Exhaust Valves for Efficient Fluid SystemsNewsAug.28,2025

-

Buy WCB Gate Valve: Robust & Reliable Industrial SolutionNewsAug.28,2025