Exploring Pricing Options for 6 Inch Check Valves and Their Applications in Various Industries

Understanding the Pricing and Value of 6-Inch Check Valves

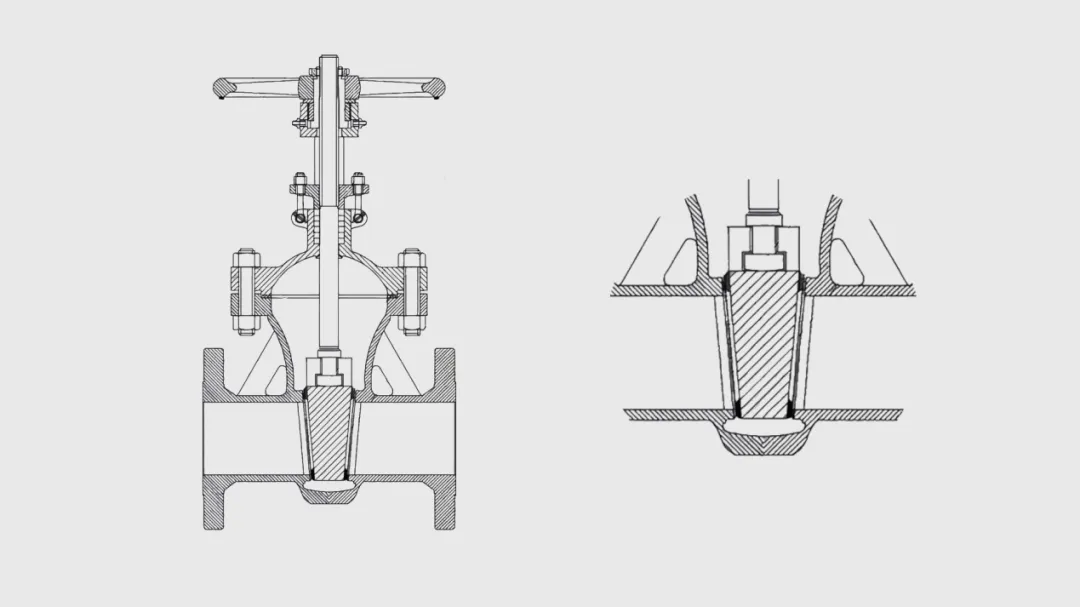

Check valves are critical components in various industrial and plumbing applications, serving a vital role in preventing backflow of fluids in piping systems. Among the various sizes available, 6-inch check valves are often discussed due to their balance of capability and installation flexibility. This article will explore the factors influencing the price of 6-inch check valves, along with their applications and benefits.

Exploring the Price Factors

The price of a 6-inch check valve can vary significantly depending on several key factors

1. Material Composition Check valves are typically made from different materials, including brass, stainless steel, plastic, and cast iron. Stainless steel and high-grade materials generally command higher prices due to their durability, corrosion resistance, and suitability for high-pressure applications. For instance, a 6-inch stainless steel check valve will often be more expensive than one made of PVC.

2. Design and Type There are several configurations of check valves, such as swing check valves and lift check valves. Each design has its unique flow characteristics and suitability for various applications, which can also affect the price. Swing check valves, for example, tend to have a lower pressure drop compared to lift check valves, making them preferable in many scenarios, possibly influencing their cost.

3. Manufacturer and Brand Just like many other products, the brand reputation plays a significant role in pricing. Established manufacturers may charge more for their products due to perceived quality, reliability, and warranty offerings. Conversely, lesser-known brands may provide budget-friendly options that could be suitable for less demanding applications.

4. Industry Standards and Certification Valves that comply with specific industry standards or certifications (like ANSI, API, or ISO) may be priced higher than non-certified ones due to the added assurance of quality and safety. Industries such as oil and gas, pharmaceuticals, and food processing often require certified components.

5. Market Demand and Supply Prices can fluctuate based on market conditions. If there is a sudden increase in demand for certain types of valves, prices may rise accordingly. Conversely, during a surplus in supply, prices could decline.

Applications of 6-Inch Check Valves

6-inch check valves are commonly used in various sectors, including

check valve 6 inch price

- Water and Wastewater Treatment In these applications, check valves prevent backflow, protecting pumps and other equipment from damage and ensuring the efficient operation of systems.

- Oil and Gas They are utilized in pipelines to prevent the reversal of flow, which can lead to significant system failures

.- HVAC Systems Check valves maintain proper air and water flow direction, enhancing the efficiency of heating and cooling systems.

- Fire Protection Systems These valves are critical for ensuring that water flows in the right direction, maintaining system integrity during emergencies.

Benefits of Using 6-Inch Check Valves

The advantages of incorporating 6-inch check valves into pipeline systems are numerous

1. Prevention of Backflow This is the primary benefit, protecting equipment and ensuring the integrity of the system.

2. Reduced Maintenance Costs High-quality check valves can significantly reduce maintenance needs and downtime, leading to lower overall operational costs.

3. Maintenance of System Efficiency By ensuring unidirectional flow, check valves help maintain pressure levels and system efficiency, which is vital in industrial applications.

Conclusion

In summary, the price of a 6-inch check valve can vary based on material, design, manufacturer reputation, certification, and market dynamics. Understanding these factors will help purchasers make informed decisions that align with their operational needs and budget constraints. Whether for residential plumbing or large-scale industrial applications, sizing and choosing the right check valve is critical for system performance and reliability.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025