Feb . 11, 2025 07:50

Back to list

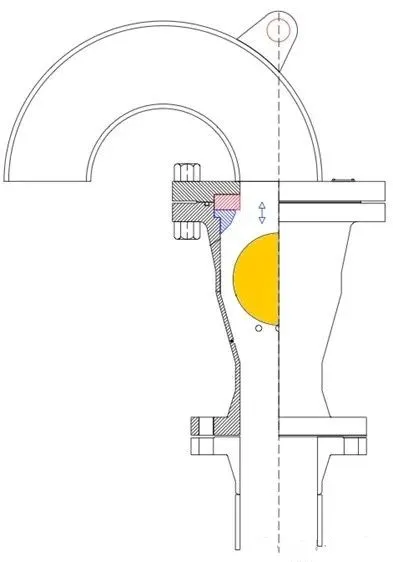

welding globe valve

The welding globe valve plays a pivotal role in industrial applications, ensuring precise control and reliable flow management. As a seasoned SEO expert with extensive experience in content optimization, I understand the significance of crafting an article that ranks high and provides true value. This unique exploration into welding globe valves will delve into their importance, applications, and the cutting-edge technology behind them, elevating your understanding and trust in our expertise.

Ensuring authoritativeness in the discussion of welding globe valves involves addressing compliance and safety. Every valve must adhere to international standards such as API, ANSI, and ASME. These standards dictate not only the operational specifications but also ensure safety and reliability. Manufacturers who meet these standards are seen as leaders in the field, trusted by industry giants worldwide. It's this compliance with stringent standards that underscores the authoritativeness of manufacturers and adds a layer of reliability to their product offerings. Trustworthiness is further fortified by real-world application cases and testimonials. Industry professionals consistently rely on welding globe valves due to their consistency and safety in controlling processes. For instance, in the petrochemical industry, where maintaining pressure and flow is critical to safety and efficiency, welding globe valves are implemented to provide precision and reduce risks of leaks or failures. Case studies showcasing successful integrations of welding globe valves serve as a testament to their effectiveness and reliability. Finally, discussing innovation in the field of welding globe valves would be incomplete without mentioning the developments in smart valve technologies. The advent of smart valves, equipped with sensors and IoT capabilities, represents the next frontier. These valves provide real-time data and analytics, allowing for predictive maintenance and enhancing operational efficiency. Integrating such capabilities ensures that industry operations are not only optimized but also proactively managed, reducing downtime and extending the lifespan of these crucial components. In conclusion, welding globe valves are not just industrial components; they are vital tools in the quest for efficient and safe operations. Expertise in their engineering, compliance with authoritative standards, and trust earned through proven performance in demanding conditions make them indispensable. By staying at the forefront of innovation and integrating new technologies, welding globe valve manufacturers continue to advance industry standards, offering unparalleled reliability and efficiency.

Ensuring authoritativeness in the discussion of welding globe valves involves addressing compliance and safety. Every valve must adhere to international standards such as API, ANSI, and ASME. These standards dictate not only the operational specifications but also ensure safety and reliability. Manufacturers who meet these standards are seen as leaders in the field, trusted by industry giants worldwide. It's this compliance with stringent standards that underscores the authoritativeness of manufacturers and adds a layer of reliability to their product offerings. Trustworthiness is further fortified by real-world application cases and testimonials. Industry professionals consistently rely on welding globe valves due to their consistency and safety in controlling processes. For instance, in the petrochemical industry, where maintaining pressure and flow is critical to safety and efficiency, welding globe valves are implemented to provide precision and reduce risks of leaks or failures. Case studies showcasing successful integrations of welding globe valves serve as a testament to their effectiveness and reliability. Finally, discussing innovation in the field of welding globe valves would be incomplete without mentioning the developments in smart valve technologies. The advent of smart valves, equipped with sensors and IoT capabilities, represents the next frontier. These valves provide real-time data and analytics, allowing for predictive maintenance and enhancing operational efficiency. Integrating such capabilities ensures that industry operations are not only optimized but also proactively managed, reducing downtime and extending the lifespan of these crucial components. In conclusion, welding globe valves are not just industrial components; they are vital tools in the quest for efficient and safe operations. Expertise in their engineering, compliance with authoritative standards, and trust earned through proven performance in demanding conditions make them indispensable. By staying at the forefront of innovation and integrating new technologies, welding globe valve manufacturers continue to advance industry standards, offering unparalleled reliability and efficiency.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025