bellows seal gate valve

Bellows Seal Gate Valve An Overview

In various industrial applications, the need for reliable fluid control is fundamental. Among the equipment used to manage fluid flow, the bellows seal gate valve stands out due to its unique design and functionality. This article explores the working principle, advantages, applications, and maintenance of bellows seal gate valves.

Understanding the Design

A bellows seal gate valve is designed to provide a tight seal when closed, preventing leaks while maintaining high integrity over time. Its construction includes a traditional gate mechanism but incorporates a unique bellows element made of flexible materials, typically metal. This bellows acts as a barrier to prevent any leakage of the medium.

The gate, which can be rising or non-rising, is operated by an actuator or handwheel. When the valve is closed, the gate seats against the valve body, and the bellows create a secondary seal around the gate stem, effectively isolating the flow and preventing leakage through the stem area. This feature is particularly important in applications where leakage could result in hazardous situations or environmental concerns.

Advantages of Bellows Seal Gate Valves

1. Leak Prevention One of the foremost advantages of bellows seal gate valves is their ability to prevent leakage. The bellows mechanism eliminates the need for traditional packing materials, which can wear out and lead to leaks over time.

2. Reduced Maintenance Because there are no packing glands to replace or maintain, bellows seal gate valves typically require less maintenance compared to conventional gate valves. This can significantly reduce operational costs and downtime.

3. Temperature & Pressure Resistance Bellows are often made from materials that can withstand extreme temperatures and pressures, making these valves suitable for a variety of processes in industries such as chemical processing, oil and gas, and power generation.

4. Corrosion Resistance Many bellows materials are resistant to corrosion, which is essential in situations where the medium is reactive or the environment is aggressive.

bellows seal gate valve

5. Safe Operations In critical applications where safety is paramount, the design of bellows seal gate valves enhances safety by reducing the risk of leaks that could potentially lead to accidents or hazardous exposure.

Applications

Bellows seal gate valves find their place in numerous industries, thanks to their reliable sealing capabilities. Common applications include

- Chemical Processing Used to control the flow of corrosive liquids and gases without the risk of leakage. - Pharmaceutical Industry Ensures a sterile environment by preventing contamination from leaks. - Power Generation Manages steam and other high-pressure fluids effectively while minimizing maintenance needs. - Oil and Gas Safeguards against environmental contamination by preventing leaks in pipelines and storage tanks.

Maintenance Considerations

While bellows seal gate valves generally require less maintenance than traditional valves, some best practices should be observed to ensure long-term performance and reliability. Regular inspections should be carried out to check for any signs of wear on the bellows or other components. Additionally, ensuring that the valve is operated according to manufacturer specifications is vital for preventing stress and potential damage to the bellows.

Operators should also develop a maintenance schedule that includes periodic testing of the valve’s sealing capability. Implementing a thorough understanding of the operating environment helps identify potential risks and enables proactive measures to maintain valve performance.

Conclusion

The bellows seal gate valve represents a significant advancement in valve technology, providing unparalleled leak prevention and reduced maintenance compared to traditional gate valves. Its robust design and effective operation make it an ideal choice for a broad range of applications across various industries. As technology continues to evolve, the importance of such valves in ensuring safe and efficient fluid control cannot be overstated. Investing in high-quality bellows seal gate valves can lead to improved reliability and operational efficiency, ultimately benefiting the overall performance of industrial systems.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

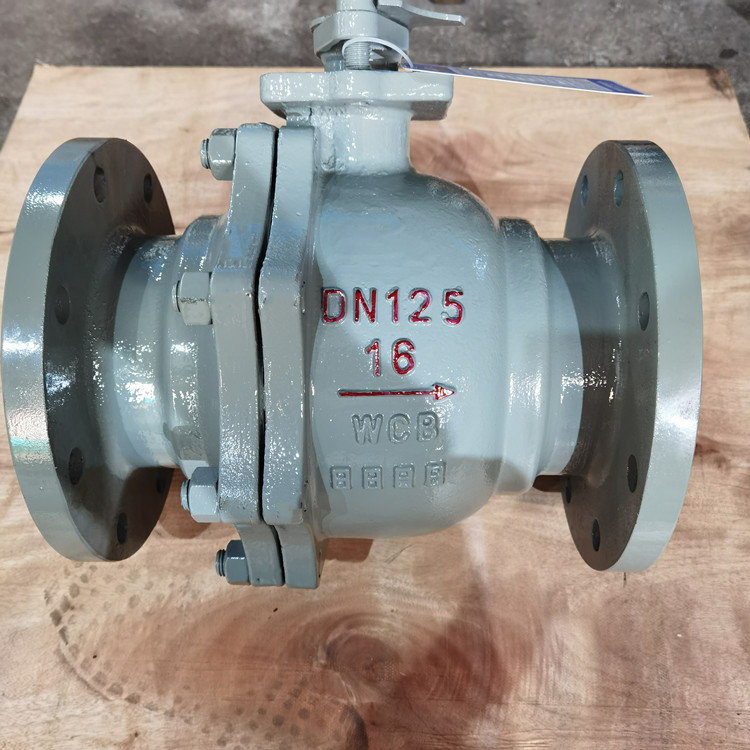

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025