DN40 Flange Specifications and Applications in Chinese Industry

Understanding China DN40 Flanges Specifications and Applications

In industrial piping systems, flanges play a crucial role in connecting pipes, pumps, valves, and other equipment. Among the various standards available, the DN40 flange is a widely used size, particularly in China. This article aims to provide insights into the specifications, types, materials, and applications of China DN40 flanges.

What is DN40?

The term DN stands for Diameter Nominal, which indicates the nominal size of the flange. DN40 refers to a nominal pipe size of 40 millimeters, which corresponds to a pipe bore or internal diameter of about 40 mm. This size is commonly utilized in various industries owing to its capability to handle a reasonable flow volume in liquid and gas applications.

Types of DN40 Flanges

There are several types of flanges used in the industry, categorized based on design features and intended uses

1. Weld Neck Flange This type of flange is known for its tapered neck, which allows for a smooth transition between the flange and the pipe. It is ideal for high-pressure applications.

2. Slip-On Flange This flange slips over the pipe and is welded in place. It's easier to align and more cost-effective than other types, making it a popular choice for various applications.

3. Blind Flange Designed to close the end of a piping system, blind flanges are essential for testing and maintenance. They can seal the pipeline effectively without requiring a connection.

4. Socket Weld Flange This flange features a recessed area for the pipe to fit into, providing a strong connection that is commonly used in high-pressure systems.

5. Lap Joint Flange Often used in conjunction with a stub end, it allows for easy assembly and disassembly, making it suitable for applications that require frequent maintenance.

Materials Used for DN40 Flanges

The choice of material for DN40 flanges is critical, as it directly impacts their performance, durability, and resistance to corrosion. Common materials include

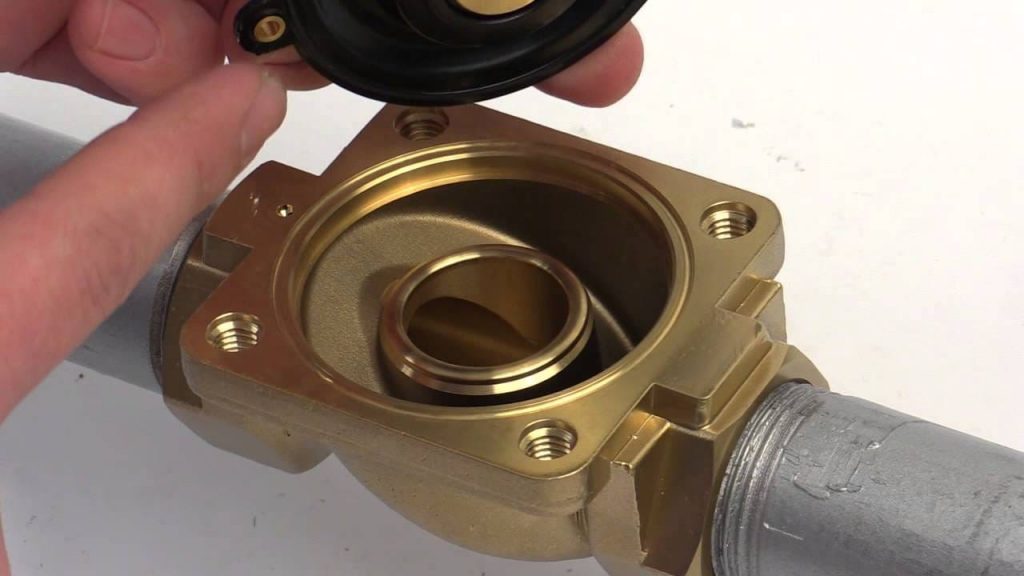

china dn40 flange

- Carbon Steel Widely used due to its strength and affordability, carbon steel flanges are ideal for oil and gas applications but may require protective coatings for corrosion resistance.

- Stainless Steel Renowned for its excellent corrosion resistance, stainless steel flanges are ideal for chemical and food processing applications where hygiene is paramount.

- Ductile Iron This material offers high strength and toughness, making it suitable for water and wastewater applications

.- Bronze Often used in marine applications due to its corrosion resistance in seawater, bronze flanges also find use in plumbing.

Applications of DN40 Flanges

DN40 flanges are utilized in various industries, including

- Oil and Gas Flanges connect pipelines transporting crude oil and natural gas, ensuring system integrity under high pressure.

- Water Supply Flanges are critical in municipal water systems, connecting water treatment plants to distribution networks.

- Chemical Processing In chemical plants, flanges facilitate connections between different components of piping systems handling corrosive substances.

- HVAC Systems DN40 flanges are used in heating, ventilation, and air conditioning systems to connect ductwork and equipment.

Conclusion

The DN40 flange is a vital component across a spectrum of industrial applications. Understanding its specifications, types, materials, and uses can aid engineers and procurement professionals in selecting the right flanges for their projects. When ensuring safety and efficiency in piping systems, the proper use of DN40 flanges cannot be understated. They serve as the backbone of reliable and effective fluid transport, crucial for the functioning of modern industry.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025