Februari . 08, 2025 04:23

Back to list

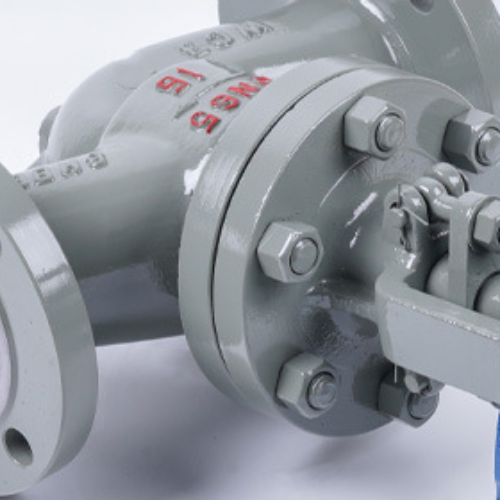

butterfly valve 10 inch

Butterfly valves are vital components in the realm of industrial applications, offering an efficient means to regulate fluid flow. The 10-inch butterfly valve, due to its size and capacity, plays a crucial role in a range of sectors, including water supply, chemical processing, and oil and gas industries. Understanding the nuances of this specific valve can provide insights into its effective use and maintenance.

From a broader industrial perspective, the 10-inch butterfly valve is lauded for its ability to deliver precise flow control without significant energy consumption. This efficiency often translates to lower operational costs and increased system reliability. Moreover, these valves support automation through integration with electronic actuators, enhancing their utility in modern industrial automation systems. Engaging with credible suppliers or manufacturers is crucial to ensure the quality and performance of 10-inch butterfly valves. Considering manufacturers that adhere to international standards and provide rigorous testing assurances can mitigate risks associated with valve failures. Consulting industry experts or established service providers can provide invaluable insights into the ideal components and configurations that match specific operational requirements. The implementation of a 10-inch butterfly valve should also take into account future scalability and system expansion. Whether the need arises for future-proofing against increased loads or adapting to new regulatory requirements, ensuring the system can accommodate such changes is pivotal. Ultimately, whether for managing the flow in a sprawling industrial setting or a localized plant operation, the 10-inch butterfly valve stands as a testament to engineering effectiveness and efficiency. Its reliable performance, coupled with modern advancements in automation, makes it an indispensable tool in the toolbox of engineers and system designers striving for excellence in fluid control applications.

From a broader industrial perspective, the 10-inch butterfly valve is lauded for its ability to deliver precise flow control without significant energy consumption. This efficiency often translates to lower operational costs and increased system reliability. Moreover, these valves support automation through integration with electronic actuators, enhancing their utility in modern industrial automation systems. Engaging with credible suppliers or manufacturers is crucial to ensure the quality and performance of 10-inch butterfly valves. Considering manufacturers that adhere to international standards and provide rigorous testing assurances can mitigate risks associated with valve failures. Consulting industry experts or established service providers can provide invaluable insights into the ideal components and configurations that match specific operational requirements. The implementation of a 10-inch butterfly valve should also take into account future scalability and system expansion. Whether the need arises for future-proofing against increased loads or adapting to new regulatory requirements, ensuring the system can accommodate such changes is pivotal. Ultimately, whether for managing the flow in a sprawling industrial setting or a localized plant operation, the 10-inch butterfly valve stands as a testament to engineering effectiveness and efficiency. Its reliable performance, coupled with modern advancements in automation, makes it an indispensable tool in the toolbox of engineers and system designers striving for excellence in fluid control applications.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025