Juni . 25, 2024 19:51

Back to list

Handbook Knife-Edge Gate Valve Operation & Maintenance Guide

A Comprehensive Guide to Manual Knife Gate Valves Function, Operation, and Maintenance

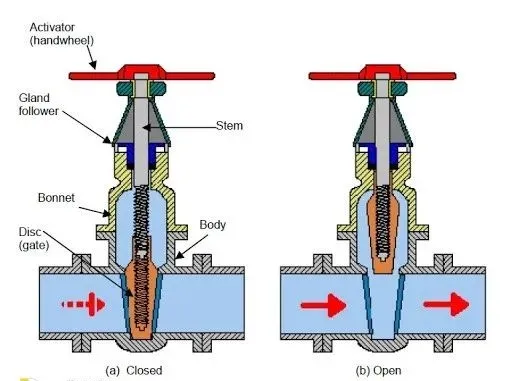

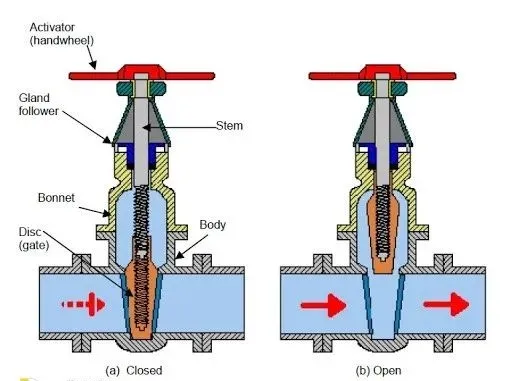

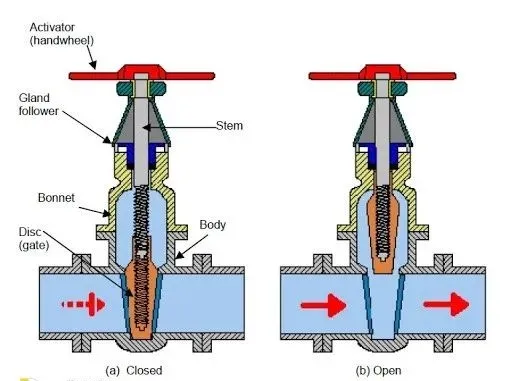

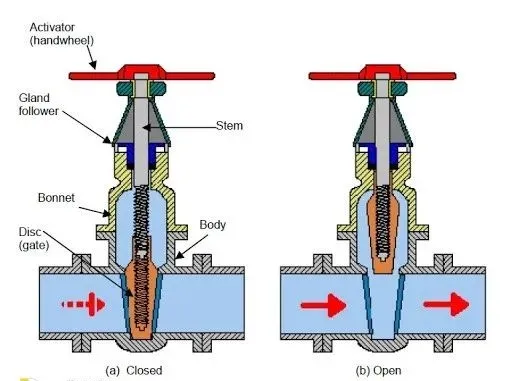

Manual knife gate valves, often referred to as lump or slurry valves, are a type of industrial control device that plays a vital role in various processes, particularly in industries handling slurries, powders, or high-viscosity fluids. These valves are designed with a distinctive blade-shaped moving element that opens and closes like a knife through a fixed frame, providing a unique and reliable method of flow regulation.

At their core, manual knife gate valves consist of a sturdy, usually metal housing containing the knife-shaped blade. The blade is hinged along one side and can be manually rotated either fully open (90 degrees) or fully closed (0 degrees) by a handle or lever. This simple yet effective mechanism allows for complete isolation of the flow when the valve is shut, making it ideal for applications where complete shut-off is crucial.

Operation of a manual knife gate valve is straightforward. To open, the operator pulls the lever or rotates the handle, lifting the blade out of the way, allowing the fluid to pass through. Conversely, closing the valve involves reversing the motion, pushing the blade back into place, blocking the flow path. It's important to note that due to the mechanical nature of these valves, they require manual intervention and are not suitable for continuous or automated operations.

Maintenance of a manual knife gate valve is essential to ensure its longevity and optimal performance. Regular inspections should include checking for wear on the blade, hinge, and any other moving parts, as well as verifying that the seal between the blade and housing is intact Regular inspections should include checking for wear on the blade, hinge, and any other moving parts, as well as verifying that the seal between the blade and housing is intact Regular inspections should include checking for wear on the blade, hinge, and any other moving parts, as well as verifying that the seal between the blade and housing is intact Regular inspections should include checking for wear on the blade, hinge, and any other moving parts, as well as verifying that the seal between the blade and housing is intact

Regular inspections should include checking for wear on the blade, hinge, and any other moving parts, as well as verifying that the seal between the blade and housing is intact Regular inspections should include checking for wear on the blade, hinge, and any other moving parts, as well as verifying that the seal between the blade and housing is intact manual knife gate valve. Lubrication of the pivot points is also critical to prevent seizing. In case of corrosion or excessive wear, the blade may need replacement, and the valve should be cleaned periodically to prevent debris buildup.

Despite their simplicity, manual knife gate valves have some limitations. They are typically less efficient than automated alternatives for continuous flow control, and their large opening and closing forces can make them challenging to operate in high-pressure or high-velocity systems. However, for applications where safety, reliability, and the ability to isolate flow are paramount, they remain a popular choice.

In conclusion, manual knife gate valves are a robust and dependable solution for managing flow in specific industrial environments. Their straightforward operation, combined with proper maintenance, ensures they continue to serve as a reliable tool for controlling slurries, powders, and other challenging materials. As with any equipment, understanding their functionality and maintaining them according to best practices is key to achieving optimal performance and extending their useful life.

manual knife gate valve. Lubrication of the pivot points is also critical to prevent seizing. In case of corrosion or excessive wear, the blade may need replacement, and the valve should be cleaned periodically to prevent debris buildup.

Despite their simplicity, manual knife gate valves have some limitations. They are typically less efficient than automated alternatives for continuous flow control, and their large opening and closing forces can make them challenging to operate in high-pressure or high-velocity systems. However, for applications where safety, reliability, and the ability to isolate flow are paramount, they remain a popular choice.

In conclusion, manual knife gate valves are a robust and dependable solution for managing flow in specific industrial environments. Their straightforward operation, combined with proper maintenance, ensures they continue to serve as a reliable tool for controlling slurries, powders, and other challenging materials. As with any equipment, understanding their functionality and maintaining them according to best practices is key to achieving optimal performance and extending their useful life.

Regular inspections should include checking for wear on the blade, hinge, and any other moving parts, as well as verifying that the seal between the blade and housing is intact Regular inspections should include checking for wear on the blade, hinge, and any other moving parts, as well as verifying that the seal between the blade and housing is intact

Regular inspections should include checking for wear on the blade, hinge, and any other moving parts, as well as verifying that the seal between the blade and housing is intact Regular inspections should include checking for wear on the blade, hinge, and any other moving parts, as well as verifying that the seal between the blade and housing is intact manual knife gate valve. Lubrication of the pivot points is also critical to prevent seizing. In case of corrosion or excessive wear, the blade may need replacement, and the valve should be cleaned periodically to prevent debris buildup.

Despite their simplicity, manual knife gate valves have some limitations. They are typically less efficient than automated alternatives for continuous flow control, and their large opening and closing forces can make them challenging to operate in high-pressure or high-velocity systems. However, for applications where safety, reliability, and the ability to isolate flow are paramount, they remain a popular choice.

In conclusion, manual knife gate valves are a robust and dependable solution for managing flow in specific industrial environments. Their straightforward operation, combined with proper maintenance, ensures they continue to serve as a reliable tool for controlling slurries, powders, and other challenging materials. As with any equipment, understanding their functionality and maintaining them according to best practices is key to achieving optimal performance and extending their useful life.

manual knife gate valve. Lubrication of the pivot points is also critical to prevent seizing. In case of corrosion or excessive wear, the blade may need replacement, and the valve should be cleaned periodically to prevent debris buildup.

Despite their simplicity, manual knife gate valves have some limitations. They are typically less efficient than automated alternatives for continuous flow control, and their large opening and closing forces can make them challenging to operate in high-pressure or high-velocity systems. However, for applications where safety, reliability, and the ability to isolate flow are paramount, they remain a popular choice.

In conclusion, manual knife gate valves are a robust and dependable solution for managing flow in specific industrial environments. Their straightforward operation, combined with proper maintenance, ensures they continue to serve as a reliable tool for controlling slurries, powders, and other challenging materials. As with any equipment, understanding their functionality and maintaining them according to best practices is key to achieving optimal performance and extending their useful life. Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025