Februari . 08, 2025 05:14

Back to list

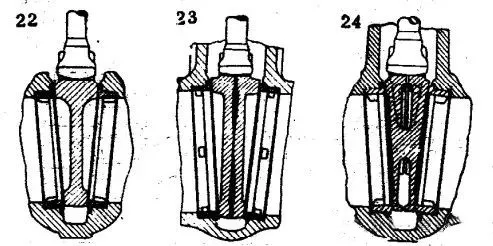

split butterfly valves

Split butterfly valves have emerged as a pivotal component in fluid control systems across various industries, owing to their unique design and substantial advantages. These valves, recognized for their efficiency and reliability, are a product of refined engineering tailored to meet the dynamic requirements of modern applications. Their design allows for effective regulation of flow, positioning them as an indispensable choice in settings that demand precise control and durability.

Furthermore, split butterfly valves are increasingly utilized in the gas and oil sector. Given the high-stakes nature of this industry, the valves must exhibit exceptional performance under extreme conditions. They are designed to provide a secure seal and maintain operational integrity under fluctuating pressures and temperatures, ensuring no leaks compromise the entire system. The trust placed in these valves within such a critical sector underscores the comprehensive experience and authoritative insights applied during their development. The innovative design and multifaceted applications of split butterfly valves exemplify their pivotal role in today’s technological advancements. Whether it is in providing efficient fluid control solutions, adapting to demanding environments, or ensuring safety in sensitive sectors, these valves prove their worth consistently. The evolution of split butterfly valves reflects a commitment to progress and quality, where expertise in fluid dynamics and material science culminates in products that are both trustworthy and efficient. For industries seeking to enhance operational efficiency and reliability, investing in split butterfly valves offers numerous benefits. Their ease of use, minimal maintenance requirements, and adaptability make them a strategic choice across various applications. As the landscape of industrial technology continues to evolve, these valves stand as a testament to the power of innovative engineering — a blend of experience and expertise that not only meets but exceeds industry demands. In conclusion, split butterfly valves represent an integral asset in the toolbox of engineers and industrial designers. Their broad applicability, coupled with proven performance metrics, positions them as a premier choice for modern industrial challenges. By leveraging advancements in material science and engineering acumen, split butterfly valves will continue to serve as a foundation for safe, efficient, and reliable industrial practices across the globe.

Furthermore, split butterfly valves are increasingly utilized in the gas and oil sector. Given the high-stakes nature of this industry, the valves must exhibit exceptional performance under extreme conditions. They are designed to provide a secure seal and maintain operational integrity under fluctuating pressures and temperatures, ensuring no leaks compromise the entire system. The trust placed in these valves within such a critical sector underscores the comprehensive experience and authoritative insights applied during their development. The innovative design and multifaceted applications of split butterfly valves exemplify their pivotal role in today’s technological advancements. Whether it is in providing efficient fluid control solutions, adapting to demanding environments, or ensuring safety in sensitive sectors, these valves prove their worth consistently. The evolution of split butterfly valves reflects a commitment to progress and quality, where expertise in fluid dynamics and material science culminates in products that are both trustworthy and efficient. For industries seeking to enhance operational efficiency and reliability, investing in split butterfly valves offers numerous benefits. Their ease of use, minimal maintenance requirements, and adaptability make them a strategic choice across various applications. As the landscape of industrial technology continues to evolve, these valves stand as a testament to the power of innovative engineering — a blend of experience and expertise that not only meets but exceeds industry demands. In conclusion, split butterfly valves represent an integral asset in the toolbox of engineers and industrial designers. Their broad applicability, coupled with proven performance metrics, positions them as a premier choice for modern industrial challenges. By leveraging advancements in material science and engineering acumen, split butterfly valves will continue to serve as a foundation for safe, efficient, and reliable industrial practices across the globe.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025