Effective Isolation Solutions Using Double Block and Bleed Plug Valves for Safety Applications

Understanding Double Block and Bleed Plug Valves

In the realm of industrial piping and fluid control, the double block and bleed (DBB) plug valve is a critical component employed to ensure safety and reliability. This valve design is particularly vital in applications where hazardous or high-pressure fluids are processed and where containment is paramount. In this article, we will explore the features, benefits, and applications of double block and bleed plug valves.

What is a Double Block and Bleed Plug Valve?

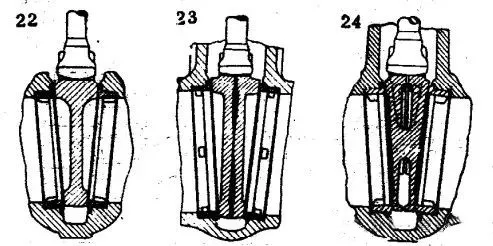

A double block and bleed plug valve is a type of valve that consists of two blocking elements (the plug valve itself) and a bleed or vent mechanism. This configuration allows for the isolation of a section of piping while simultaneously providing a means to vent any trapped fluid, ensuring that maintenance or inspection procedures can be safely performed without the risk of fluid release.

The typical setup includes two plug valves installed in series, with a drain or bleed line positioned between them. This arrangement allows for the capability to double block the line – isolating the upstream and downstream pressures – while providing a safe environment to verify the absence of pressure or fluid via the bleed valve.

Key Features

1. Safety Assurance The primary advantage of double block and bleed plug valves is the enhanced safety it provides. By isolating upstream and downstream systems, it protects personnel and equipment when maintenance or repairs are necessary.

2. Compact Design The DBB configuration allows for a more compact design compared to traditional isolation methods. This space-saving aspect is essential in facilities where space is limited, making installation simpler and potentially reducing costs.

3. Ease of Operation Plug valves are known for their straightforward operation. They can be opened and closed with minimal effort, ensuring quick access during emergencies or routine operations.

4. Versatility These valves can be used across various industries, including oil and gas, chemical manufacturing, and water treatment, making them a versatile choice for many applications.

double block & bleed plug valve

Applications

Double block and bleed plug valves are commonly used in scenarios that demand high safety standards. Some of the typical applications include

- Oil and Gas Pipelines In upstream and midstream facilities, DBB plug valves are crucial for isolating sections of pipelines during maintenance, ensuring that the high-pressure lines do not pose a risk to operators.

- Chemical Processing In industrial settings where hazardous chemicals are managed, the ability to safely block and vent systems is vital for compliance with health and safety regulations.

- Power Generation DBB plug valves are employed in power plants to facilitate maintenance of steam and water systems, ensuring both safety and efficiency in operations.

- Water Treatment Facilities These valves can be used in water and wastewater treatment to isolate sections of the piping for repairs or inspections without contaminating other areas of the system.

Conclusion

The double block and bleed plug valve represents a significant advancement in valve technology, addressing critical safety and efficiency issues faced in various industrial applications. By providing a reliable solution for isolation and venting, these valves play an essential role in ensuring safe operation and maintenance of piping systems. As industries continue to demand higher safety standards, the importance of DBB plug valves is expected to grow, marking them as a cornerstone of fluid control technology in modern engineering. Adopting such technology can lead to safer working environments and more efficient operational protocols in the long run.

-

Top-Quality Pipe and Pipe Fittings for Reliable Fluid SystemsNewsAug.28,2025

-

Reliable Slip On Flange Manufacturer for Industrial ExcellenceNewsAug.28,2025

-

Premium Rubber Expansion Joints for Piping SystemsNewsAug.28,2025

-

Premium Electric Actuators for Smart Automation SolutionsNewsAug.28,2025

-

Innovative Flange Solutions for Modern Plumbing NeedsNewsAug.28,2025

-

High-Performance Exhaust Valves for Efficient Fluid SystemsNewsAug.28,2025

-

Buy WCB Gate Valve: Robust & Reliable Industrial SolutionNewsAug.28,2025