Leading Manufacturer of High-Quality Flap Valves for Reliable Industrial Applications and Solutions

The Role and Importance of Flap Valve Manufacturers

Flap valves are essential components in various industrial applications, particularly in wastewater management, stormwater control, and system protection. These valves operate using a simple yet effective mechanism, allowing fluid flow in one direction while preventing backflow. As industries increasingly prioritize efficiency and sustainability, the demand for high-quality flap valves has risen, making flap valve manufacturers a vital part of the industrial landscape.

Understanding Flap Valves

Flap valves, also known as check valves or non-return valves, are designed to permit flow in one direction while automatically closing when flow attempts to reverse. Their design typically features a hinged flap or disc that opens under pressure and closes when the pressure drops, stopping any backflow. These valves are essential in applications where backflow can cause damage, contamination, or inefficiency.

Key Applications

1. Wastewater Management One of the primary applications of flap valves is in wastewater treatment facilities. They prevent backflow from the sewage system during heavy rain or flooding, protecting treatment plants and ensuring that wastewater does not contaminate clean water supplies.

2. Stormwater Control In urban settings, flap valves are crucial in stormwater management systems, facilitating the drainage of excess water while preventing the ingress of floods. This is particularly important as climate change leads to more frequent and intense weather patterns.

3. Industrial Processes Many manufacturing processes require a reliable means of controlling fluid flow. Flap valves are commonly used to regulate the flow of materials in processing plants, ensuring efficiency and safety.

4. Marine Applications In nautical environments, flap valves are used to prevent water from entering vessels in case of leaks or flooding, thereby safeguarding equipment and personnel.

The Manufacturing Process

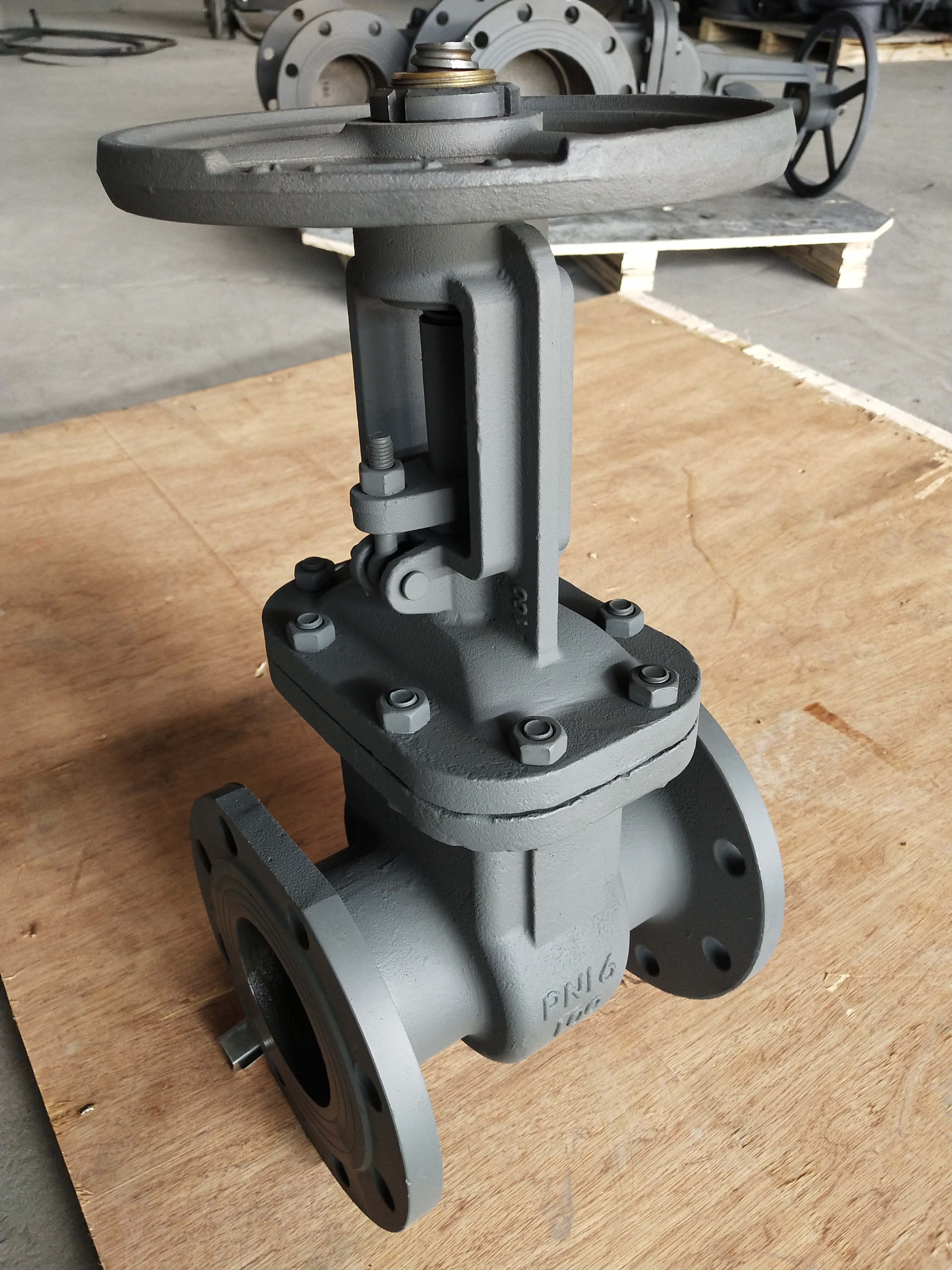

flap valve manufacturer

The manufacturing of flap valves involves several critical steps to ensure quality and durability. Leading manufacturers utilize advanced materials, such as stainless steel, plastic, and rubber, to withstand harsh conditions, including corrosive environments and fluctuating pressures. The design phase discusses various parameters, including size, flow capacity, and pressure ratings, to meet specific application needs.

Modern flap valve manufacturers employ sophisticated manufacturing techniques, including precision machining and casting, to produce components with tight tolerances. Quality control is paramount; rigorous testing procedures—ranging from hydrostatic pressure tests to endurance testing—ensure that each valve performs effectively under various environmental conditions.

Choosing a Flap Valve Manufacturer

When selecting a flap valve manufacturer, several factors should be considered

- Experience and Reputation Manufacturers with a proven track record in the industry are more likely to provide reliable products. Check client reviews and case studies. - Material Quality Ensure the manufacturer uses high-grade materials that are suitable for the intended application and resistant to environmental stresses.

- Customization Options Depending on the specific needs of your project, the ability to customize flap valves can be invaluable. Look for manufacturers that offer tailored solutions.

- Support and Service After-sale support and customer service are critical for addressing any issues that may arise post-installation. A manufacturer that offers comprehensive support can save time and resources.

Conclusion

Flap valve manufacturers play a crucial role in many industries by providing reliable, efficient solutions for controlling fluid flow and preventing backflow. As the demand for sustainable and effective water management and industrial processes continues to grow, the importance of these manufacturers is becoming more significant. Choosing the right flap valve manufacturer can lead to enhanced operational efficiency, reduced risk of contamination, and ultimately, better protection for both public health and the environment.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025