Selecting the Appropriate 6% Pipe Flange for Your Project Needs and Specifications

Understanding 6% Pipe Flange A Comprehensive Overview

In the world of piping systems, the term flange is one that often arises. Flanges are essential components that allow for the connection of pipes and other equipment in various systems, facilitating the operation of industries ranging from oil and gas to water treatment. This article delves into the specifics of a 6% pipe flange, discussing its design, application, and importance in various industrial contexts.

What is a Pipe Flange?

A pipe flange is a type of fitting used to join two pieces of pipe or other equipment in a piping system. Flanges are typically circular pieces of metal with holes around the perimeter for bolts. They create a tight seal between two pipes, preventing leaks and allowing for maintenance and repair without the need to dismantle the entire assembly. Flanges play a crucial role in ensuring the integrity and efficiency of a piping system.

Understanding the 6% Specification

When it comes to 6% pipe flange, the term typically relates to a specification regarding the flange’s design or performance characteristics. In industrial contexts, specifications like 6% can refer to certain tolerances, dimensions, or even the amount of allowable deformation under pressure.

- Tolerances In the manufacturing of flanges, a tolerance is the acceptable limit or variation in the dimension of the flange. A 6% tolerance might mean that the flange can vary 6% around a specified measurement, which is critical for ensuring the flange aligns correctly with the mating components.

- Pressure Ratings Sometimes, a percentage like 6% could refer to the design pressure of the flange in relation to the standard pressure ratings. Understanding how much pressure a flange can handle is essential, specifically in high-pressure applications where a failure could lead to catastrophic results.

Design and Material Considerations

The design and material selection are vital for a pipe flange's efficacy. Common materials include carbon steel, stainless steel, and alloys, each chosen based on the specific application, environmental conditions, and the nature of the fluid being transported.

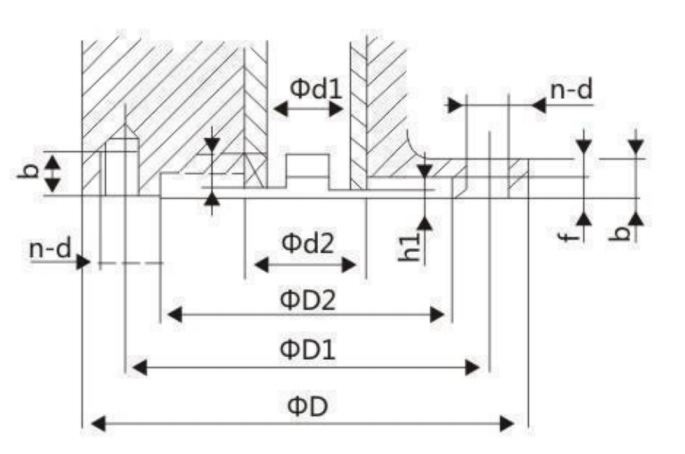

6 pipe flange

- For example Stainless steel flanges are used in corrosive environments due to their resistance to rust and oxidation. In contrast, carbon steel might be preferred for applications involving high strength and toughness.

In terms of design, flanges can come in several types, including slip-on, weld neck, blind, and threaded flanges. The choice of design often depends on the requirements of the piping system. A weld neck flange, for example, provides a powerful joint for high-pressure situations, while slip-on flanges can be easier and less expensive to install.

Applications

The applications for 6% pipe flanges are extensive. In the oil and gas industry, flanges are used in pipelines to transport fuel, gas, and other resources. In water treatment facilities, flanges help in connecting various components of the piping system that delivers clean water to municipal supplies.

Additionally, in energy production, flanges are critical in the setup of cooling systems in power plants, where maintaining efficiency and safety is paramount. The chemical process industry also relies heavily on flanges, where robust connections are essential for the integrity of the system handling reactive materials.

Importance of Proper Installation

The installation of pipe flanges cannot be overlooked. Improper installation can lead to misalignment, excessive stress on the piping system, and even catastrophic failures. It is vital that flanges are installed correctly, using the right tools and techniques to ensure a secure fit and seal.

Regular inspections and maintenance are also essential to detect any potential wear or damage, particularly in high-stress environments. This proactive approach will help to avoid leaks and losses, which can have significant financial and environmental consequences.

Conclusion

In conclusion, the 6% pipe flange is an integral component in various piping systems across different industries. Understanding its specifications, design, and application is crucial for engineers and technicians working with these systems. Flanges not only provide a means of connection but also ensure the safety, efficiency, and reliability of complex piping networks. As industries continue to innovate and seek improved performance, the relevance of robust and reliable pipe flanges like those adhering to the 6% specification will only grow.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025