Suppliers of Mini Ball Valves for Various Industrial Applications

Exploring Mini Ball Valve Suppliers A Comprehensive Guide

When it comes to fluid control systems, mini ball valves play a significant role in managing the flow of liquids and gases. These compact devices offer high durability, reliable sealing, and easy operation, making them highly sought after in various industries, from manufacturing and plumbing to food processing and pharmaceuticals. As demand increases, so does the number of mini ball valve suppliers, each claiming to offer the best products. This article aims to provide insights on selecting the right mini ball valve suppliers and understanding the market landscape.

Understanding Mini Ball Valves

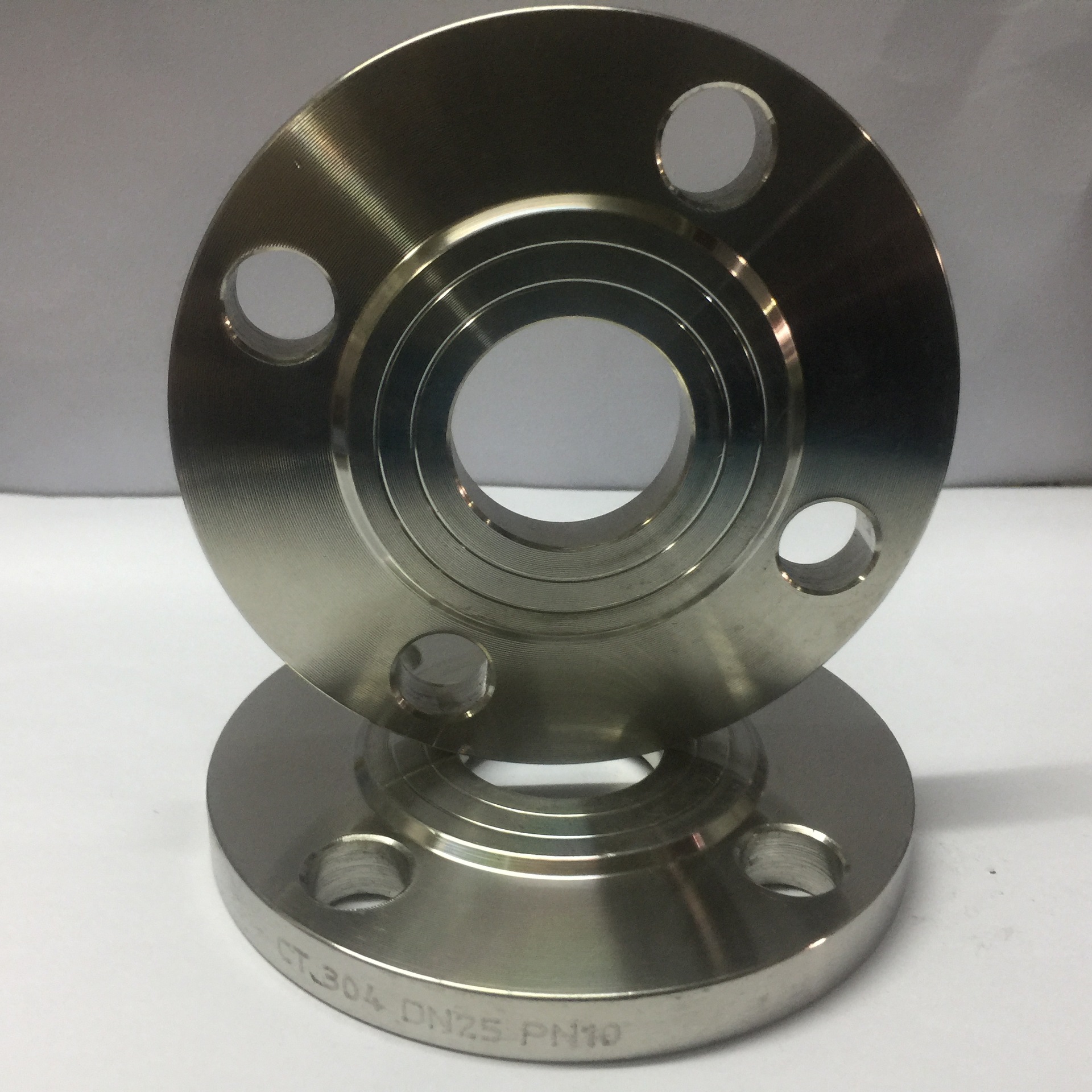

Mini ball valves are characterized by their small size, often integrated into systems where space is limited. Unlike larger ball valves, mini versions maintain the same functionality; they utilize a spherical disc to control flow. The advantage of using a mini ball valve lies in its ability to provide a tight seal, even under high pressure and temperature conditions.

These valves are generally constructed from a variety of materials, including brass, stainless steel, and PVC, allowing them to be used in different environments and applications. Their compact design makes them ideal for applications in automotive systems, water lines, and even laboratory equipment.

Selecting the Right Supplier

When searching for mini ball valve suppliers, one should consider several factors to ensure quality and reliability

1. Experience and Reputation Look for suppliers with a well-established history in the industry. Companies that have been in business for several years often demonstrate stability and a track record of quality. Reading customer reviews and testimonials can provide insight into their reputation.

2. Product Range Suppliers should offer a wide variety of mini ball valves to meet diverse application needs. Whether you require valves made from different materials or specific sizes, a supplier with a broad inventory can cater to your requirements effectively.

3. Quality Assurance Check if the supplier adheres to industry standards and quality certifications, such as ISO 9001. Quality assurance processes ensure that the valves meet certain performance and safety criteria, which is critical in avoiding failures in sensitive applications.

mini ball valve suppliers

4. Manufacturing Capabilities Understand the manufacturing process of the supplier. Those who utilize advanced technology and quality control measures during production can provide more reliable products. This also includes checking for customization options to better suit specific application requirements.

5. Customer Service and Support A good supplier not only provides quality products but also offers excellent customer service. This includes assistance in choosing the right products, timely delivery, and after-sales services. Quick response times and knowledgeable support staff can significantly enhance the overall purchasing experience.

6. Pricing and Payment Terms While price shouldn’t be the sole determinant in selecting a supplier, it is still an important factor. Compare prices across different suppliers, but be cautious of unusually low prices that may indicate lower quality. Additionally, understanding payment terms and bulk order discounts can help optimize costs.

Market Trends

The markets for mini ball valves are continually evolving, influenced by advancements in technology and shifts in consumer demand. Here are a few noteworthy trends

- Increased Automation Many industries are leaning towards automation. Suppliers are now offering mini ball valves that can be integrated with smart systems for remote operation and monitoring.

- Sustainable Materials As environmental concerns grow, many suppliers are developing mini ball valves made from eco-friendly materials or those that promote sustainability in operations.

- Customization The demand for customized solutions is rising, pushing suppliers to offer more tailored products that fit specific industrial needs.

Conclusion

Choosing the right mini ball valve supplier is crucial for ensuring the efficiency and reliability of fluid control systems. By considering factors such as reputation, product range, quality assurance, and customer service, businesses can find a supplier that meets their needs effectively. As the market continues to evolve, staying informed about trends and innovations will further empower buyers to make informed choices. Investing in quality mini ball valves and building a strong relationship with a reliable supplier will lead to enhanced system performance and long-term success.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025