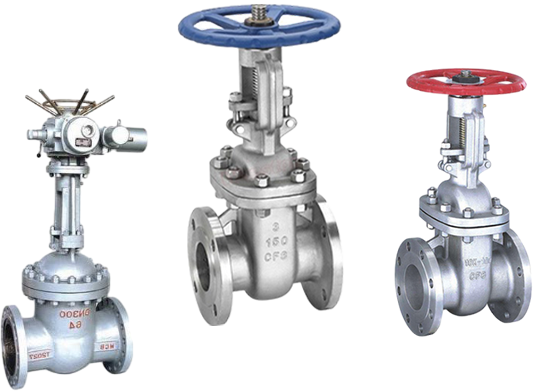

2 in gate valve suppliers

Exploring 2% Gate Valve Suppliers A Comprehensive Overview

The global valve market has witnessed significant growth over the past several years, driven by the expanding demand in various industries such as oil and gas, water treatment, power generation, and chemical manufacturing. Among the various types of valves available, gate valves hold a crucial position due to their essential functions. This article will delve into the specifics of 2% gate valve suppliers, discussing their significance, characteristics, and the factors to consider when choosing a supplier.

Understanding Gate Valves

Gate valves are linear motion valves primarily used to start or stop fluid flow. They are characterized by a wedge-shaped metal piece that slides between two seats to either allow or obstruct flow. Unlike other valve types that can throttle flow, gate valves are designed for full open or closed positions, ensuring minimal pressure drop and turbulence when fully opened. The nomenclature of 2% gate valves refers to specific performance standards or quality assurance metrics that suppliers aim to meet, ensuring that the valves perform optimally under various conditions.

Importance of Choosing the Right Supplier

Selecting the right gate valve supplier is critical for ensuring the reliability and efficiency of any industrial operation. A reputable supplier will offer gates that meet the necessary regulatory standards and specifications while providing a history of their products' performance. When it comes to 2% gate valve suppliers, certain factors must be considered

1. Quality and Compliance Suppliers should adhere to international standards like ANSI, API, or ISO. This compliance ensures that the valves produced can withstand the operational pressures and temperatures typical for their intended applications.

2. Material and Durability The material used in manufacturing gate valves is vital. Common materials include stainless steel, carbon steel, and various alloys. The choice depends on the application's nature, such as corrosive environments or high-temperature conditions. Suppliers that offer a range of materials allow for customization based on specific industrial needs.

2 in gate valve suppliers

3. Performance Testing Effective suppliers conduct rigorous testing to ensure their valves can perform under expected conditions. This encompasses pressure tests, durability assessments, and leakage tests. Suppliers who provide detailed certifications and test reports on their products are often more trustworthy.

4. Customer Support and Service A reliable supplier should offer robust customer service, from the initial inquiry to after-sales support. This includes providing technical assistance, timely deliveries, and effective communication channels for addressing queries or concerns.

5. Reputation and Reviews A supplier's market reputation can be indicative of their reliability. Researching customer reviews, testimonials, and case studies can provide insights into previous performance and service quality.

Leading 2% Gate Valve Suppliers

Several companies have earned recognition in the gate valve manufacturing sector due to their commitment to quality and innovation. Major suppliers not only offer a diverse range of gate valves but also focus on exporting to various markets globally. Some leading names in this sector include

- Flowserve Known for its large portfolio of valves, Flowserve’s gate valves are engineered for reliability and efficiency. - Emerson Emerson provides advanced technology and valve solutions, ideal for complex industrial applications. - Crane Co. With a longstanding history, Crane Co. specializes in high-performance gate valves that are widely used across different sectors.

Conclusion

The selection of a 2% gate valve supplier is a critical decision with far-reaching implications for industrial operations. By considering factors such as quality, material durability, performance testing, customer service, and supplier reputation, businesses can ensure that they partner with a supplier capable of meeting their specific needs. As industries continue to evolve, having reliable gate valve suppliers will remain essential for maintaining operational efficiency and safety.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025