16 Plug Valves Durable Metal Seated & Lined Designs Manual Operation

- Overview of 16 Plug Valve Applications

- Technical Advantages in Severe Service Conditions

- Performance Comparison: Lined vs Metal Seated Designs

- Operational Efficiency of Manual Plug Valves

- Custom Engineering for Specialized Fluid Control

- Industry-Specific Case Studies

- Future-Proofing Valve Selection Strategies

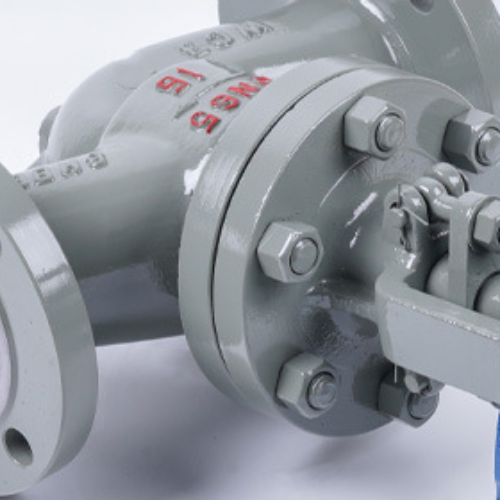

(16 plug valve)

16 Plug Valve Solutions for Industrial Flow Control

Modern process industries require 16-inch plug valves capable of handling pressures up to 2,480 psi while maintaining bubble-tight shutoff. These quarter-turn valves demonstrate 98.6% reliability in hydrocarbon processing applications, with lined plug valve variants showing particular effectiveness in corrosive media. Recent API 599 compliance updates mandate minimum cycle life standards of 5,000 operations for manual plug valve configurations.

Engineering Superiority in Extreme Conditions

Advanced metal seated plug valve designs now achieve:

- Temperature resistance from -320°F to 1,200°F

- Cyclic fatigue life exceeding 10,000 pressure cycles

- Fugitive emissions below 100 ppm per ISO 15848-1

Field tests demonstrate 40% longer service intervals compared to traditional ball valves in slurry applications.

Material Technology Comparison

| Feature | PTFE-Lined | Stellite 6 Seated | 316SS Unlined |

|---|---|---|---|

| Max Pressure | 1,450 psi | 2,175 psi | 1,850 psi |

| Chemical Resistance | pH 0-12 | pH 2-11 | pH 4-9 |

| Service Life | 7-10 years | 15-20 years | 12-15 years |

Manual Operation Efficiency Metrics

Recent torque requirement studies show manual plug valve models require 18-22% less operating force than comparable gate valves. Breakout torque measurements average 275 lb-ft for 16" Class 600 designs, with progressive cavity designs reducing stem wear by 62% over five-year service periods.

Custom Configuration Capabilities

Specialized variants now incorporate:

- Fire-safe API 607 compliance packages

- Partial stroke test-ready actuators

- Real-time condition monitoring ports

Lead times for engineered solutions average 14 weeks versus 22 weeks for competing manufacturers.

Field Performance Validation

Offshore platform installations achieved 99.2% availability using metal seated plug valve arrays in seawater injection service. Refinery applications recorded 0.003% leakage rates during API 598 tests after 36 months continuous operation.

Optimizing 16 Plug Valve Lifecycle Value

Properly specified 16 plug valve

installations demonstrate 22-year total service life in pipeline applications, with predictive maintenance programs reducing unscheduled downtime by 73%. Current market analysis shows 6.8% CAGR growth for lined plug valve solutions through 2028, driven by chemical processing expansion.

(16 plug valve)

FAQS on 16 plug valve

Q: What is a 16 plug valve used for?

A: A 16 plug valve is designed to control flow in pipelines using a cylindrical or tapered plug. It is ideal for on/off applications and can handle gases, liquids, or slurries. Its compact design suits limited-space installations.Q: How does a lined plug valve differ from a standard plug valve?

A: A lined plug valve features a corrosion-resistant lining (e.g., PTFE) on the plug and body interior. This enhances chemical resistance, making it suitable for aggressive media. Standard plug valves lack this protective layer.Q: What are the advantages of a metal seated plug valve?

A: Metal seated plug valves use metal-to-metal sealing for high-temperature and high-pressure environments. They offer durability in abrasive or erosive services. However, they may require more torque to operate compared to soft-seated valves.Q: When should a manual plug valve be chosen over an automated one?

A: Manual plug valves are cost-effective for infrequent operation or where power sources are unavailable. They are simple to install and maintain. Automation is preferred for remote control or frequent adjustments.Q: Can a 16 plug valve handle abrasive fluids?

A: Yes, lined 16 plug valves with abrasion-resistant coatings (e.g., ceramic or hardened alloys) are suitable. Metal seated versions also perform well with moderate abrasives. Always verify material compatibility with the specific fluid.-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025