needle globe valve manufacturer

The Needle Globe Valve An Essential Component of Fluid Control Systems

In the world of fluid control systems, the needle globe valve has established itself as a crucial component for regulating flow in various industrial applications. As a specialized type of globe valve, it is designed to provide precision control over the flow of liquids and gases, making it an ideal choice for processes where accuracy is paramount. This article delves into the features, working principles, advantages, and applications of needle globe valves, while also highlighting some of the leading manufacturers in the industry.

Understanding the Needle Globe Valve

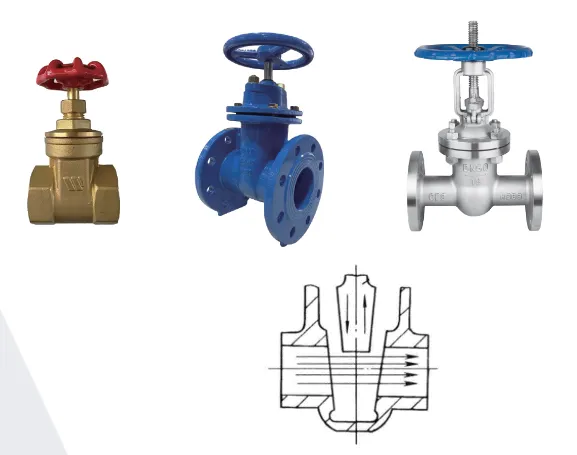

The needle globe valve is characterized by its long, tapered needle-like stem that allows for fine adjustments of fluid flow. Unlike regular globe valves, which have a more rounded disc, the needle design enables high-precision throttling capabilities. This feature is particularly significant in applications requiring meticulous control, such as in chemical processing, oil and gas industries, and laboratory environments.

The primary components of a needle globe valve include the body, inlet and outlet flanges, a bonnet, and the needle-shaped plug. The unique design ensures that when the valve is opened, the flow path is gradually widened, providing a smoother transition and minimizing turbulence, which can be critical for sensitive applications.

Working Principle of Needle Globe Valve

The functioning of a needle globe valve is relatively straightforward. When the handwheel is turned, the needle plug moves up or down in relation to the seat, allowing the operator to control the flow rate. By adjusting the position of the plug, users can either restrict or permit flow through the valve. The tapered design of the plug aids in achieving this precision, as the surface area in contact with the seating increases gradually, thus providing enhanced throttling capacity.

Moreover, the design of the needle globe valve also allows for bi-directional flow, which ensures that it can be installed in any orientation, making it a versatile choice for various piping systems.

Advantages of Needle Globe Valves

1. Precision Control The most significant advantage of needle globe valves is their ability to provide precise control over fluid flow. This makes them essential in applications that demand high accuracy.

2. Durability Needle globe valves are generally made from robust materials, such as stainless steel or brass, which can withstand demanding operating conditions, including high pressure and temperature variations.

3. Low Flow Resistance The smooth, gradual design of the flow path minimizes resistance, leading to improved system efficiency and reduced energy consumption.

4. Versatility Needle globe valves can handle a wide range of fluids, including corrosive substances, making them suitable for diverse applications in different industries.

5. Ease of Operation With a simple design and reliable performance, needle globe valves can be operated easily, often requiring minimal maintenance.

needle globe valve manufacturer

Applications of Needle Globe Valves

Needle globe valves are utilized across various industries due to their unique features. Some common applications include

- Chemical Processing Used for regulating the flow of chemicals in reactors and pipelines, ensuring safety and precision. - Oil and Gas Employed in drilling and production operations to control flow rates effectively.

- Water Treatment Implemented in water management systems to maintain the desired flow levels throughout the treatment process.

- HVAC Systems Essential for balancing and regulating flow in heating and cooling systems.

- Laboratory Equipment Utilized in various scientific experiments where precise fluid control is required.

Leading Needle Globe Valve Manufacturers

The market for needle globe valves features several reputable manufacturers known for their high-quality products and commitment to innovation. Some of the prominent names in the industry include

1. Swagelok Renowned for its comprehensive range of valves, including needle globe models, Swagelok emphasizes quality and reliability in fluid system components.

2. Parker Hannifin A global leader in motion and control technologies, Parker offers an extensive selection of needle valves designed for longevity and performance.

3. Val-Matic Known for its innovative valve solutions, Val-Matic manufactures needle globe valves that are engineered to meet the demands of various industries.

4. Apollo Valves With a strong focus on producing durable and efficient valve solutions, Apollo Valves is a trusted name in the fluid control market.

5. Emerson A major player in the automation and control sector, Emerson provides advanced valve technologies and controls, including needle globe valves.

In conclusion, needle globe valves play a pivotal role in fluid control systems by enabling precise regulation of flow rates. Their robust design, versatility, and efficiency make them indispensable in various applications across multiple industries. With leading manufacturers continually improving and innovating, the future of needle globe valves looks promising, ensuring they remain at the forefront of fluid control solutions.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025