Oca . 09, 2025 12:43

Back to list

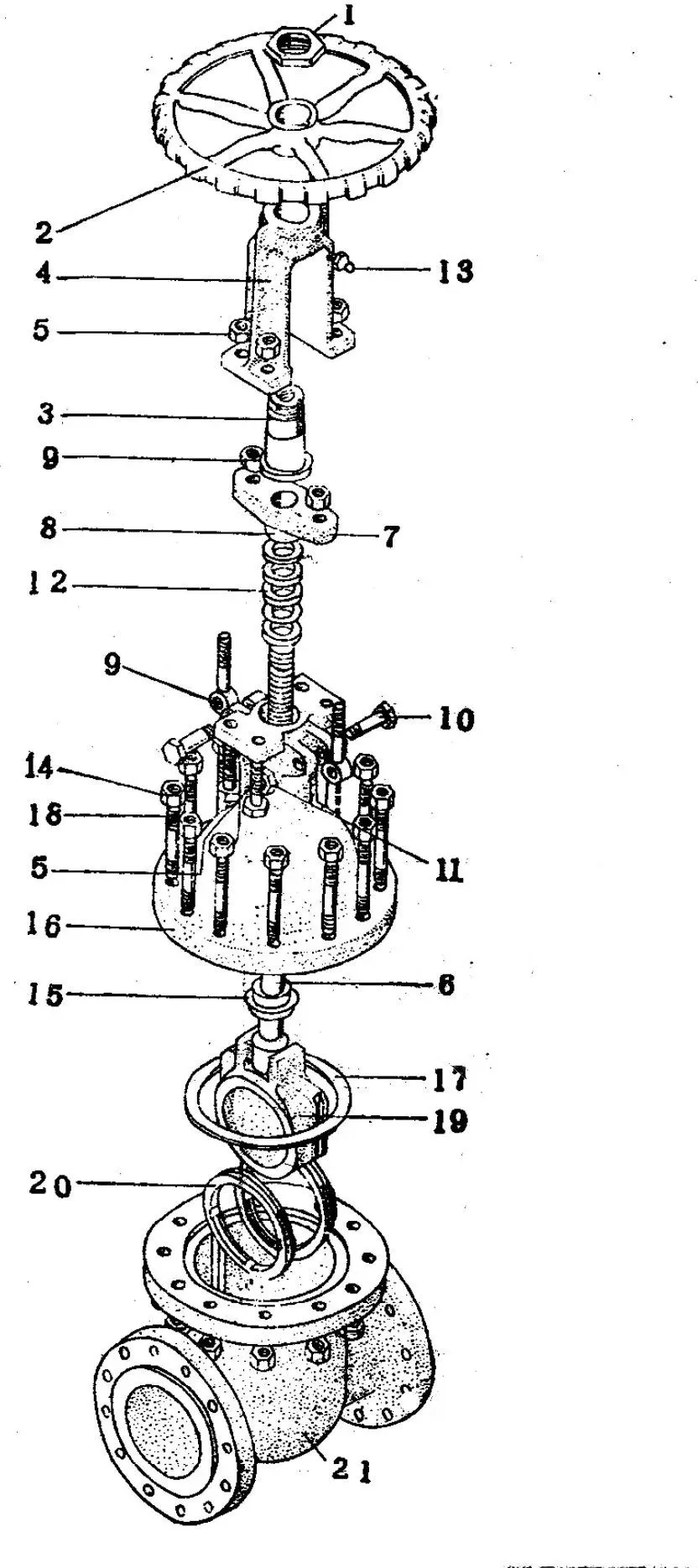

globe valve

Selecting the right valve type is crucial for ensuring optimal performance in any fluid control process. Among various types, the globe valve stands out due to its excellent throttling capabilities and robust design. With years of hands-on experience in fluid dynamics and valve technologies, I can confidently assert that globe valves are indispensable in achieving precise control over fluid flow in diverse applications.

Globe valves also boast a reputation for trustworthiness, primarily due to their fail-safe nature. The manual operation mechanism allows for quick shutdown in emergencies, providing an added layer of safety in critical circumstances—an essential feature appreciated by engineers and safety officers alike. This reliability cultivates confidence among users, knowing that the valve will effectively manage flow under varied conditions without compromising system integrity. Furthermore, from an authoritative perspective, the selection of globe valves is supported by industry standards and certifications that underscore their quality and reliability. Compliance with international standards such as ANSI, ASME, and API guarantees that these valves not only meet but exceed the requisite benchmarks for performance and safety. Industry leaders continue to endorse globe valves' unparalleled capabilities for modulating flow and maintaining system equilibrium, solidifying their status as a trusted component in fluid control systems. In conclusion, the expertise and real-world insights gathered over the years corroborate that globe valves are an optimal choice for applications demanding precise flow control and robust durability. Their unparalleled capacity to operate under diverse conditions while ensuring minimal leakage and efficient shut-off makes them indispensable in achieving operational excellence. Embracing globe valves means investing in a future where system efficiency, safety, and reliability are non-negotiable priorities.

Globe valves also boast a reputation for trustworthiness, primarily due to their fail-safe nature. The manual operation mechanism allows for quick shutdown in emergencies, providing an added layer of safety in critical circumstances—an essential feature appreciated by engineers and safety officers alike. This reliability cultivates confidence among users, knowing that the valve will effectively manage flow under varied conditions without compromising system integrity. Furthermore, from an authoritative perspective, the selection of globe valves is supported by industry standards and certifications that underscore their quality and reliability. Compliance with international standards such as ANSI, ASME, and API guarantees that these valves not only meet but exceed the requisite benchmarks for performance and safety. Industry leaders continue to endorse globe valves' unparalleled capabilities for modulating flow and maintaining system equilibrium, solidifying their status as a trusted component in fluid control systems. In conclusion, the expertise and real-world insights gathered over the years corroborate that globe valves are an optimal choice for applications demanding precise flow control and robust durability. Their unparalleled capacity to operate under diverse conditions while ensuring minimal leakage and efficient shut-off makes them indispensable in achieving operational excellence. Embracing globe valves means investing in a future where system efficiency, safety, and reliability are non-negotiable priorities.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025