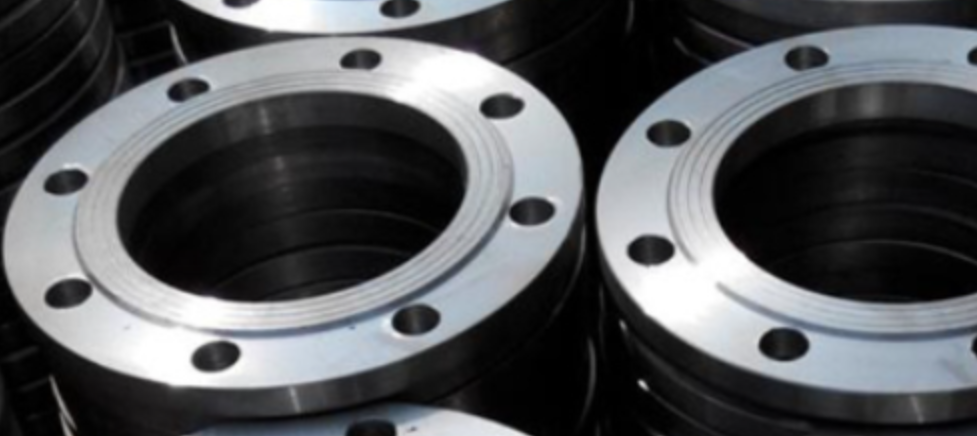

Types of gaskets for flanges selection guide

Types of gaskets for flanges selection guide involves nuanced considerations that extend beyond basic material compatibility, focusing on specialized performance traits critical for unique industrial environments. Flanges are important components for connecting pipes, valves, equipment and accessories to achieve safe and reliable connections. Flanges can be divided into various types according to different standards and uses. The right choice of gaskets directly impacts the integrity of these connections, making it essential to understand how types of gaskets for flanges, flange for sale, and pipe flange types interact under specific conditions. Hebei Yaosheng lndustry located in B # industrial park, Xushui district, Baodingcity, Hebei province, is a professional company that offers expertise in matching gaskets to flanges, ensuring optimal performance in applications ranging from high-pressure steam systems to corrosive chemical pipelines.

Compressed Fiber Gaskets in Types of Gaskets for Flanges

- Binder Compatibility: Types of gaskets for flangesinclude compressed fiber variants, where the binder (e.g., nitrile or neoprene) must resist the medium. Hebei Yaosheng recommends nitrile-bound gaskets for oil services, as they withstand hydrocarbon exposure without swelling, unlike natural rubber alternatives.

- Thickness Tolerance Control: These types of gaskets for flanges require precise thickness (±0.1mm) to ensure uniform compression. The company’s calibration process achieves this, preventing over-compression in low-pressure (PN6) water pipelines where flange warping is a risk.

- Reinforcement Layer Selection: For types of gaskets for flanges in vibration-prone systems (e.g., pump connections), Hebei Yaosheng adds a tinned steel core to compressed fiber gaskets, reducing creep by 40% compared to unreinforced versions.

Metal Jacketed Gaskets in Pipe Flange Types

- Corrugation Profile Design: Pipe flange types with raised faces (RF) benefit from metal jacketed gaskets with 0.5mm-deep corrugations, which enhance sealing on slightly uneven surfaces. Hebei Yaosheng’s CNC-pressed profiles ensure consistent corrugation, critical for PN16 steam flanges.

- Inner Liner Material Matching: For pipe flange types handling corrosive media, the gasket’s inner liner (PTFE or graphite) must outperform the jacket material. The company specifies 316L stainless steel jackets with PTFE liners for 316 flange systems in chemical processing, preventing galvanic corrosion.

- Temperature Cycling Resistance: Pipe flange types in thermal swing services (e.g., batch reactors) require metal jacketed gaskets with annealed cores. Hebei Yaosheng’s annealing process reduces brittleness, allowing gaskets to withstand 500+ cycles from -20℃ to 200℃ without cracking.

Spiral Wound Gaskets in Flange for Sale

- Filler Material Purity: Flange for sale often pairs with spiral wound gaskets, where the filler (graphite or PTFE) must be 99.9% pure. Hebei Yaosheng’s graphite fillers contain minimal ash, preventing contamination in food-grade water pipelines using stainless steel flanges.

- Wind Density Uniformity: The wire winding density (turns per cm) in these gaskets affects pressure retention. For high-pressure (PN25) flange for sale applications, the company uses 5 turns/cm, ensuring the gasket withstands 25bar without blowout, unlike lower-density alternatives.

- Outer Ring Compatibility: Flange for sale with large diameters (DN1600) require gaskets with reinforced outer rings. Hebei Yaosheng’s carbon steel rings (CT20) resist deformation under bolt torque, maintaining alignment in municipal water main flanges.

Elastomeric Gaskets in Pipe Flange Types

- Hardness Gradient Engineering: Pipe flange types for vacuum systems use elastomeric gaskets with 60-70 Shore A hardness, balancing flexibility and resilience. Hebei Yaosheng’s formulation achieves this, preventing gasket extrusion in PN10 vacuum flanges common in pharmaceutical processing.

- Molding Flash Removal: These pipe flange types demand gaskets with smooth edges to avoid crevice corrosion. The company’s post-molding trimming process eliminates flash, a critical detail for 304L stainless steel flanges in high-purity water systems.

- Peroxide Curing Advantage: For pipe flange types in high-temperature water (≤120℃), peroxide-cured EPDM gaskets outperform sulfur-cured versions. Hebei Yaosheng’s peroxide process enhances heat resistance, extending gasket life in boiler feedwater flanges by 2+ years.

|

Specification |

Details |

|

Standard |

GOST |

|

Pressure |

PN6, PN10, PN16, PN25 |

|

Size |

DN10-DN1600 |

|

Tip |

PLATE RF |

|

Malzeme |

CS CT20, 16MN; SS 304/304L, 316/316L |

|

Coating |

Rust-proof oil |

Types of Gaskets for Flanges FAQS

How do I match types of gaskets for flanges in corrosive environments?

Types of gaskets for flanges in corrosive service require material compatibility: use PTFE-lined metal gaskets for 316L flanges with acid media, and graphite gaskets for CS CT20 flanges in alkaline systems. Hebei Yaosheng tests gasket-medium pairs to ensure no chemical interaction.

What is the best gasket for large-diameter flange for sale?

Large-diameter (DN1600) flange for sale benefits from spiral wound gaskets with outer rings, which distribute bolt pressure evenly. Hebei Yaosheng’s custom rings prevent gasket creep in these oversized flanges, common in wastewater treatment plants.

How do pipe flange types influence gasket thickness selection?

Pipe flange types with raised faces (RF) need 3mm-thick gaskets for PN16 pressure, while flat-faced flanges require 1.5mm gaskets to avoid excessive compression. Hebei Yaosheng provides thickness charts tailored to each flange type.

Can types of gaskets for flanges be reused after disassembly?

Types of gaskets for flanges like spiral wound can be reused once if inspected for damage, but compressed fiber gaskets should be replaced. Hebei Yaosheng advises against reusing gaskets in critical services (e.g., steam) to prevent sudden failure.

What coating on flange for sale affects gasket selection?

Flange for sale with rust-proof oil coatings require gaskets resistant to oil absorption, such as PTFE or metal jacketed variants. Hebei Yaosheng warns that oil-soaked fiber gaskets lose compressibility, compromising seals in fuel pipelines.

-

3 types of check valves maintenance tipsHaberlerAug.23,2025

-

Ball valves types with trunnion mounted designHaberlerAug.23,2025

-

Butterfly valve company production capabilitiesHaberlerAug.23,2025

-

Fisher globe valve technical specificationsHaberlerAug.23,2025

-

Wedge gate valve suppliers quality standardsHaberlerAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaHaberlerAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryHaberlerAug.18,2025