Understanding the Differences Between Check Valves and Non-Return Valves in Fluid Systems

Understanding Check Valves and Non-Return Valves

Check valves and non-return valves are essential components in various fluid systems, primarily designed to control the flow of liquids and gases. Despite their similar functionalities, they serve distinct purposes and are utilized in different applications. This article aims to explore the key features, functions, and applications of check valves and non-return valves.

What is a Check Valve?

A check valve, also known as a one-way valve, is designed to allow fluid to flow in one direction while preventing backflow. This mechanism is fundamental in preventing contamination, preserving system integrity, and ensuring operational efficiency. Check valves come in various designs, including swing check valves, lift check valves, and diaphragm check valves, each suited for specific applications and flow characteristics.

Key Features

1. Unidirectional Flow The primary characteristic of a check valve is its ability to permit fluid to flow in one direction only. This is accomplished through a movable disc, ball, or diaphragm that opens with forward flow and closes when there is back pressure.

2. Automated Operation Unlike some valves that require manual operation, check valves function automatically, responding to the fluid flow and pressure changes. This feature makes them highly reliable in various settings.

3. Minimal Pressure Drop Check valves are designed to maintain a low-pressure drop across their body, ensuring that the system operates efficiently without significant loss of energy.

What is a Non-Return Valve?

A non-return valve is essentially another term used to describe a check valve. In many industries, the term non-return valve is commonly used in the context of specific applications, such as sewage systems, pump installations, and HVAC systems, where backflow could lead to inefficiencies, contamination, or equipment damage.

Key Features

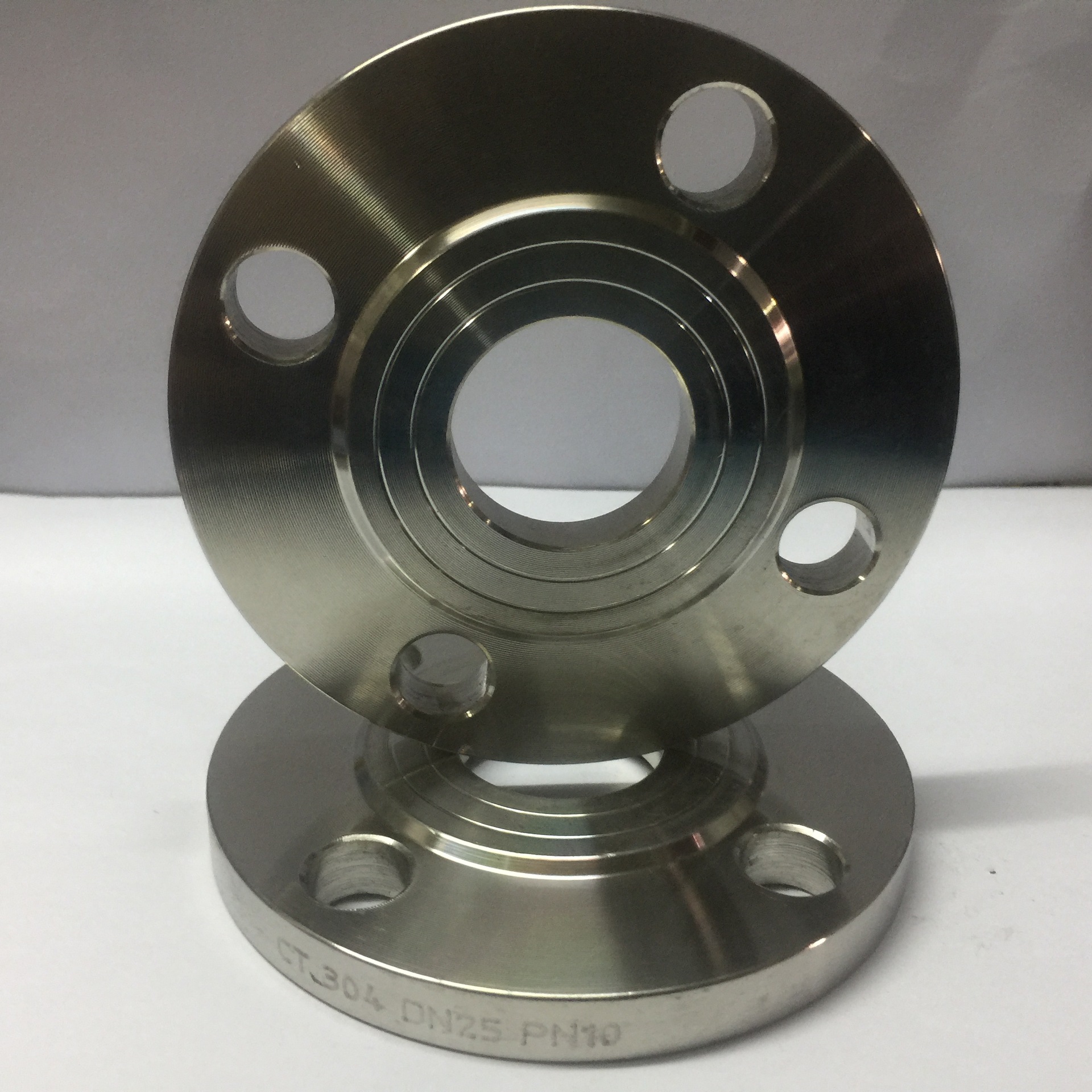

check valve and non return valve

1. Prevention of Backflow Just like check valves, non-return valves are crucial in preventing the backflow of fluids, thereby protecting the system from potential hazards.

2. Versatile Applications Non-return valves are widely used in plumbing, irrigation, and industrial applications, where maintaining unidirectional flow is critical to system operations.

3. Simple Design Non-return valves often have simple mechanisms, which contribute to their reliability and ease of maintenance.

Applications of Check and Non-Return Valves

Both check valves and non-return valves find applications across a multitude of industries, including

1. Water and Wastewater Treatment These valves are vital in municipal water systems to ensure that treated water does not flow back into contaminated sources.

2. Oil and Gas In oil refineries and gas transportation systems, check valves prevent backflow that could compromise safety and operational integrity.

3. Heating, Ventilation, and Air Conditioning (HVAC) Non-return valves help maintain proper airflow in HVAC systems, ensuring efficiency and comfort in residential and commercial buildings.

4. Industrial Processes Both types of valves are integral to various industrial processes where flow control is essential, including chemical manufacturing and pharmaceutical production.

Conclusion

In summary, check valves and non-return valves play critical roles in fluid systems by ensuring unidirectional flow and preventing backflow. Their applications span across various industries, highlighting their importance in maintaining system integrity and efficiency. Understanding their features and functions is essential for anyone involved in the design, operation, or maintenance of systems utilizing these valves. As technology advances, the development of more sophisticated and efficient valve designs continues to enhance their performance and reliability in diverse applications.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025