Wafer Disc Check Valve - Low Pressure Drop & Durable Design

Wafer disc check valves, often termed as disc check valve wafer type or wafer disk check valve, are at the forefront of fluid control in today’s industrial landscape, finding applications from petrochemical to metallurgy and water supply systems. The H74H / X-10 / 16/25/40 wafer disc check valve, as highlighted by HBYS Valves, integrates advanced material science and precision engineering for reliable, energy-efficient performance. This guide explores global industry trends, key specifications, technical advantages, leading suppliers, bespoke solutions, vivid application cases, and trustworthy data-driven analysis to empower your choice.

Industry Trends & Market Overview: Wafer Disc Check Valves

- Global demand for wafer type disc check valves is forecasted to reach USD 1.42 billion by 2026, growing at 5.8% CAGR (Source: Grand View Research, 2023).

- Energy efficiency & compact design are key drivers, particularly in pipeline infrastructure modernizations.

- Stringent ISO and ANSI standards drive compliance in critical sectors (oil & gas, chemical processing, water treatment, etc.).

- Growing customization needs push for advanced sealing, anti-corrosive materials (e.g., CF8M, duplex steel), and tight shut-off performance.

Technical Anatomy: Wafer Disc Check Valve Construction & Parameters

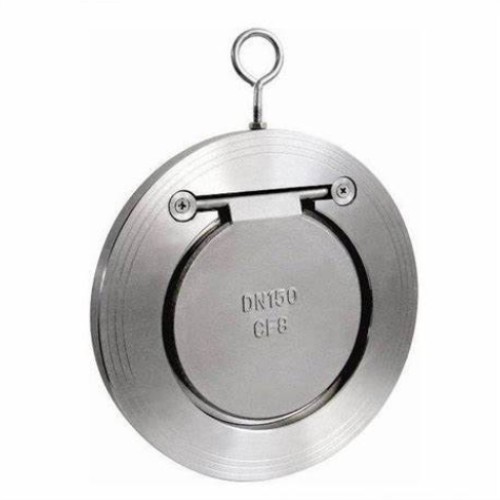

What is a Wafer Disc Check Valve?

Wafer disc check valve (also known as wafer type disc check valve or wafer disk check valve) is a non-return valve designed for installation between flanges (EN, ANSI, GB standards) with a spring-loaded, centrally seated disc. It prevents backflow and water hammer, guaranteeing one-directional flow with minimal pressure drop.

- Body Options: CF8/CF8M (stainless steel), WCB (carbon steel), duplex steel, etc.

- Disc: Precision cast, CNC machined. Optional: hard-faced for erosive media.

- Seat: Metal-to-metal, soft seat (EPDM, PTFE) available for tight shut-off.

- Spring: High-grade SS304/SS316 for reliable closure action and corrosion resistance.

- End Connections: Wafer (between flanges), dual-plate, swing type design.

| Parameter | Typical Value / Range | Description |

|---|---|---|

| Size Range | DN40 ~ DN600 (1.5" ~ 24") | Wide compatibility from pipelines to industrial systems |

| Pressure Rating | PN10, PN16, PN25, PN40 / Class 150, 300 | For various pressure classes |

| Material | CF8, CF8M, WCB, duplex SS, bronze | Selection based on medium & corrosion resistance |

| Seal Type | Metal/Soft seat | Ensures bubble-tight sealing |

| Working Temp. | -29°C ~ 400°C (depends on material) | Suitable for diverse operating environments |

| Standard Compliance | ISO 5208, API 594, BS 1868 | Global certification and acceptance |

| Flow Direction | Unidirectional | Prevents backflow |

Manufacturing Process: From Raw Material to Quality Valve

(CF8, CF8M, WCB)→ Casting & Forging→ CNC Machining→ Assembly→ Testing/Inspection→ Surface Treatment & Packaging

1. Material Certification: 100% PMI (Positive Material Identification) before casting.

2. Precision Machining: CNC lathes ensure dimensional tolerances meet ISO 5208.

3. Assembly Cleanliness: Ultra-clean assembly areas prevent contamination.

4. Testing: Hydrostatic & seat leakage tests per API 598/ISO 5208.

5. Final Inspection: Visual, functional, marking, and documentation checks before shipment.

6. Surface Protection: Anti-corrosive paint or pickling passive finish as per end application.

Wafer disc check valve manufacturing process

Product Focus: H74H / X-10 / 16/25/40 Wafer Disc Check Valve Specifications

The H74H / X-10 / 16/25/40 wafer disc check valve by HBYS Valves combines state-of-the-art metallurgy with robust sealing technology to deliver unmatched performance for critical flow control needs.

| H74H / X-10 / 16/25/40 Technical Data | |

|---|---|

| Nominal Size | DN40 ~ DN600 |

| Pressure Rating | PN10, PN16, PN25, PN40 |

| Body Material | Stainless Steel (CF8/CF8M), Carbon Steel (WCB) |

| Disc Material | CF8, CF8M, Cu, Alloy, Duplex SS |

| Seal Type | Metal Seat / EPDM / PTFE / NBR |

| Face-to-Face | EN 558, API 594 |

| Applicable Medium | Water, Oil, Gas, Steam, Corrosive Fluids |

| Operating Temp. | -29°C to 400°C (per material) |

| Standard | ISO 5208, API 598, EN1092-1/ANSI B16.5 |

| Coating / Finish | Epoxy / Pickling & Passivation |

| Springs | SS304, SS316 |

| Dual Certification | CE, ISO9001:2015 |

How Does It Compare? Technical Specs & Brands Side-by-Side

| Brand/Model | Pressure | Size (DN) | Material | Seal Type | Certifications | Service Life |

|---|---|---|---|---|---|---|

| HBYS H74H/X-10/16/25/40 | PN10–40 | 40–600 | CF8/CF8M/WCB/Duplex | Metal/EPDM/PTFE | ISO, CE, API | 15+ years |

| Velan D-010 | PN10–25 | 50–400 | SS316/CF8M/WCB | Metal/PTFE | API, ISO | 12+ years |

| Kitz DC | PN10–16 | 50–400 | CF8/Brass/Bronze | EPDM/Buna | ISO, JIS | 10+ years |

| SSV 740 | PN10–40 | 40–500 | CF8/CF8M | Metal/Soft | ISO, API | 12+ years |

“Wafer disc check valves with ISO/API compliance and full PMA documentation are increasingly favored by global EPC & process plant clients for reliability and total cost of ownership.”

— Valve World Magazine 2023

Advantages & Innovations of the Wafer Disc Check Valve Series

- Ultra-Compact, Low Pressure Drop: Minimal installation space, direct fit between flanges, pressure loss

- Outstanding Corrosion Resistance: CF8M/Duplex grades resist aggressive media—far exceeding API 594 requirements.

- Spring-Loaded Fast Closing: Prevents water hammer & reverse flow—vital for pumps, thermal systems, and steam circuits.

- Broad Application Temperature: Reliable tight shut-off from cryogenic -29°C service to steam up to 400°C.

- Lifecycle Tested: >20,000 open/close cycles at rated pressure with no seat leakage (

- Easy Maintenance: Fewer moving parts, modular seat design for swift field replacement.

End-User Customization & Engineering Solutions

HBYS Valves enables precision-engineered, project-based customization for wafer disc check valve orders:

- Material Matching: From CF8M stainless for acid, to duplex steel for offshore/oil sectors, and bronze for seawater.

- Face-to-Face, End Connection: Conforms to all major standards (EN 558/API 594, ANSI/GB). Custom face-to-face available.

- Soft or Metal Sealing: Depending on pressure, media, and shut-off requirements.

- Documentation: CMTR, hydrostatic/sealing test reports, NDT (RT, MT, PT), full traceability files.

- Special Coatings: Epoxy for potable water, HVOF spray for abrasive/corrosive environments.

- Testable Features: Optional third-party inspection (SGS, TUV, BV), fire-safe tests.

Application Scenarios: Real-World Case Studies

186 units H74H wafer disc check valve (DN150, CF8M) installed in sulfuric acid header lines.

Result: Achieved zero internal leakage; annual maintenance downtime reduced by 85%.

Customer rating: “Prefabricated sizing and corrosion resistance saved us weeks of fieldwork.”

Project: DN400 wafer disk check valve (WCB+EPDM) for high-flow station.

Result: Pressure loss reduced by 23%, no noise or water hammer for >18 months.

Audit report: “API 598 hydrostatic compliance verified onsite.”

47 sets wafer type disc check valve (Duplex, PN25) in glycol cooling loops.

Result: Cyclic service at 135℃ for 24/7 duty; no seat wear after 20,000 cycles.

Customized H74H wafer disc check valve (duplex steel, NACE MR0175) for produced water injection system.

Result: 30% longer lifespan vs. previous swing check solution.

Professional FAQ: Wafer Disc Check Valves

Q1: What are the main body materials used in wafer disc check valve manufacturing?

A: The most common are CF8 (AISI 304 SS), CF8M (AISI 316 SS), WCB (carbon steel), duplex and sometimes bronze. Choice depends on fluid medium, pressure, and temperature.

Q2: Which sealing types are available and how do they affect valve performance?

A: Metal seat (stainless-to-stainless, hard-faced) provides high temperature/abrasion resistance, while soft seat (EPDM, PTFE) ensures bubble-tight shut-off for water or low-pressure gas.

Q3: How is valve size (DN/ANSI) selected?

A: Size is determined by pipeline inner diameter and flow. Standard range: DN40~DN600 (also 1.5”–24” ANSI). Always match to flange standards (EN, ANSI, GB, etc.).

Q4: What installation standards should be followed?

A: Conform to relevant flange and valve standards: EN 1092-1, ANSI B16.5, face-to-face: EN 558/API 594. Install with flow arrow matching actual system direction.

Q5: What are typical tests conducted before shipment?

A: Hydrostatic shell/seat pressure, air seat leakage, and visual inspection per API 598 & ISO 5208. Some projects require ultrasonic (UT), magnetic particle (MT), or radiography (RT).

Q6: What is the typical lead/production time for custom H74H wafer disc check valve?

A: Standard models: 7–20 days. Special/custom: 25–40 days, depending on material, test scope and order quantity.

Q7: How is lifetime or cycle testing carried out?

A: Cyclic open/close testing is done at rated pressure and temperature (typically 10,000–20,000 cycles) to validate seat wear and spring integrity, ensuring durability as per ISO/API guidelines.

Delivery, Warranty & Support

- Delivery Time: Stock & standard valves in 7–20 working days; special materials or certifications may require up to 40 days.

- Warranty: 18–36 months from shipment, covering design & manufacturing (see official HBYS Terms).

- Technical Support: Free pre-sales selection, post-sales installation guidance, and detailed O&M manuals.

- Certifications: ISO9001:2015, CE, API 6D, with available 3.1/3.2 material and testing certificates.

- Customer Service: 24/7 online query service, full document package, international logistics assistance.

- Third-Party Inspection: Support for SGS, BV, TUV, and customer witnessed FAT/pressure tests.

References & Authoritative Resources

- API 594/ISO 5208 Valve Testing Standard: www.api.org / www.iso.org

- Valve World Magazine – Industry Trends (2023): www.valve-world.net

- Grand View Research - Check Valve Market: grandviewresearch.com

- Global Valve Forums: ENG-TIPS Valve Selection Forum

- Customer Case Studies: Internal HBYS project documentation (2021–2023)

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025