Янв . 31, 2025 02:52

Back to list

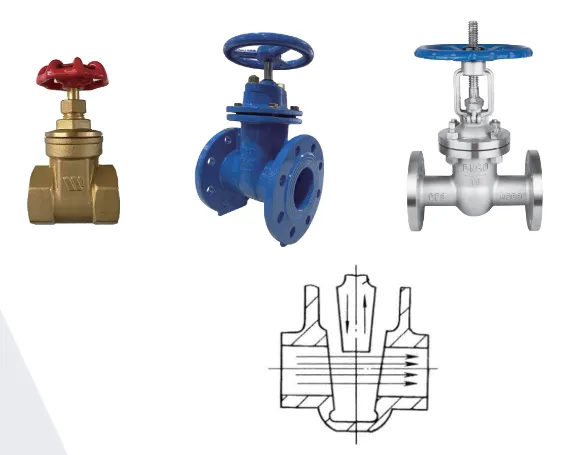

bellow sealed gate valves

In the complex world of industrial engineering and piping systems, bellow sealed gate valves stand as pivotal components that ensure safety, efficiency, and reliability. These valves are revered in industries where leakage concerns are paramount, such as chemical processing, nuclear power generation, and pharmaceuticals. Their superior design addresses common issues associated with traditional valve systems. This article delves into the unique features of bellow sealed gate valves, providing insights from firsthand experience, shedding light on their specialized applications, and reinforcing their standing as industry essentials.

Trustworthiness is an attribute that bellow sealed gate valves have earned through their impeccable performance record. In sectors where the cost of failure can be astronomical, relying on components that deliver as promised is non-negotiable. Feedback from plant operators underscores a consistent message the reliability of bellow sealed gate valves is a significant factor in process optimization and risk reduction strategies. Moreover, their ability to perform seamlessly over extended periods is a testament to the quality manufacturing practices adhered to by leading valve producers. The design considerations for these valves incorporate numerous technical nuances aimed at enhancing performance. For instance, the optimized flow path minimizes pressure drop across the valve, ensuring that systems maintain their efficiency. In practical terms, this feature translates into energy savings and enhances the overall performance of the piping system. Insights from field-operational data indicate that the marginally higher initial cost of bellow sealed valves is quickly offset by their reduced lifecycle cost compared to traditional valves. The adoption of bellow sealed gate valves is further driven by regulatory compliance requirements, especially in industries such as pharmaceuticals and food processing, where contamination can be a critical issue. The bellow design inherently mitigates the risk of external contamination entering the process stream, thus aligning with strict hygiene standards and regulatory mandates. On-site inspections and audits, as experienced by various industries, often recognize these valves as compliant with the most stringent criteria. In conclusion, bellow sealed gate valves represent a confluence of engineering ingenuity and operational necessity. They stand as indispensable components that provide unparalleled advantages in safety, reliability, and efficiency. For any industry where valve failure is not an option, and where production and staff safety are paramount, these valves offer a solution that expertly balances all key operational requirements. The compelling combination of their design features, backed by authoritative endorsements and proven trustworthiness, makes bellow sealed gate valves not just an asset but a necessity in modern industrial operations. As industries continue to push towards safer, more efficient technologies, the role of these valves is set to grow even more significant, ensuring their continued presence as a critical component of industrial infrastructure.

Trustworthiness is an attribute that bellow sealed gate valves have earned through their impeccable performance record. In sectors where the cost of failure can be astronomical, relying on components that deliver as promised is non-negotiable. Feedback from plant operators underscores a consistent message the reliability of bellow sealed gate valves is a significant factor in process optimization and risk reduction strategies. Moreover, their ability to perform seamlessly over extended periods is a testament to the quality manufacturing practices adhered to by leading valve producers. The design considerations for these valves incorporate numerous technical nuances aimed at enhancing performance. For instance, the optimized flow path minimizes pressure drop across the valve, ensuring that systems maintain their efficiency. In practical terms, this feature translates into energy savings and enhances the overall performance of the piping system. Insights from field-operational data indicate that the marginally higher initial cost of bellow sealed valves is quickly offset by their reduced lifecycle cost compared to traditional valves. The adoption of bellow sealed gate valves is further driven by regulatory compliance requirements, especially in industries such as pharmaceuticals and food processing, where contamination can be a critical issue. The bellow design inherently mitigates the risk of external contamination entering the process stream, thus aligning with strict hygiene standards and regulatory mandates. On-site inspections and audits, as experienced by various industries, often recognize these valves as compliant with the most stringent criteria. In conclusion, bellow sealed gate valves represent a confluence of engineering ingenuity and operational necessity. They stand as indispensable components that provide unparalleled advantages in safety, reliability, and efficiency. For any industry where valve failure is not an option, and where production and staff safety are paramount, these valves offer a solution that expertly balances all key operational requirements. The compelling combination of their design features, backed by authoritative endorsements and proven trustworthiness, makes bellow sealed gate valves not just an asset but a necessity in modern industrial operations. As industries continue to push towards safer, more efficient technologies, the role of these valves is set to grow even more significant, ensuring their continued presence as a critical component of industrial infrastructure.

Next:

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025