double flanged butterfly valve supplier

The Importance of Choosing a Reliable Double Flanged Butterfly Valve Supplier

When it comes to fluid control systems, butterfly valves are a go-to choice for many engineers and procurement managers, thanks to their simplicity, cost-effectiveness, and compact design. Among the various types of butterfly valves, double flanged butterfly valves stand out for their robust construction and suitability for high pressure and temperature applications. However, the effectiveness and reliability of these valves heavily depend on the supplier selected. This article highlights the significance of choosing a reputable double flanged butterfly valve supplier.

Understanding Double Flanged Butterfly Valves

A double flanged butterfly valve features flanges on both ends, allowing for direct mounting to pipe systems. This design ensures a secure connection and provides better alignment and support, making it suitable for larger pipe diameters and more demanding applications. These valves are widely used in industries such as water treatment, chemical processing, and power generation due to their robust sealing capabilities and ability to handle a variety of fluids.

Quality Standards and Certifications

One of the primary reasons for sourcing double flanged butterfly valves from a reliable supplier is the assurance of quality standards and certifications. Established suppliers adhere to industry standards like ISO 9001, API, and ANSI, which dictate rigorous criteria for design, manufacturing, and testing. By choosing a supplier with the right certifications, customers can ensure that the valves meet the necessary performance and safety standards, reducing the likelihood of failures and costly downtime.

Material Selection and Durability

The materials used in the construction of double flanged butterfly valves significantly affect their performance and longevity. High-quality suppliers offer valves made from durable materials like stainless steel, ductile iron, and various alloys, which provide excellent resistance to corrosion, wear, and temperature fluctuations. This ensures that the valves can operate efficiently in harsh environments without compromising functionality. In contrast, low-quality materials can lead to premature wear, leaks, and failures, resulting in operational inefficiencies and increased costs.

Customization and Technical Support

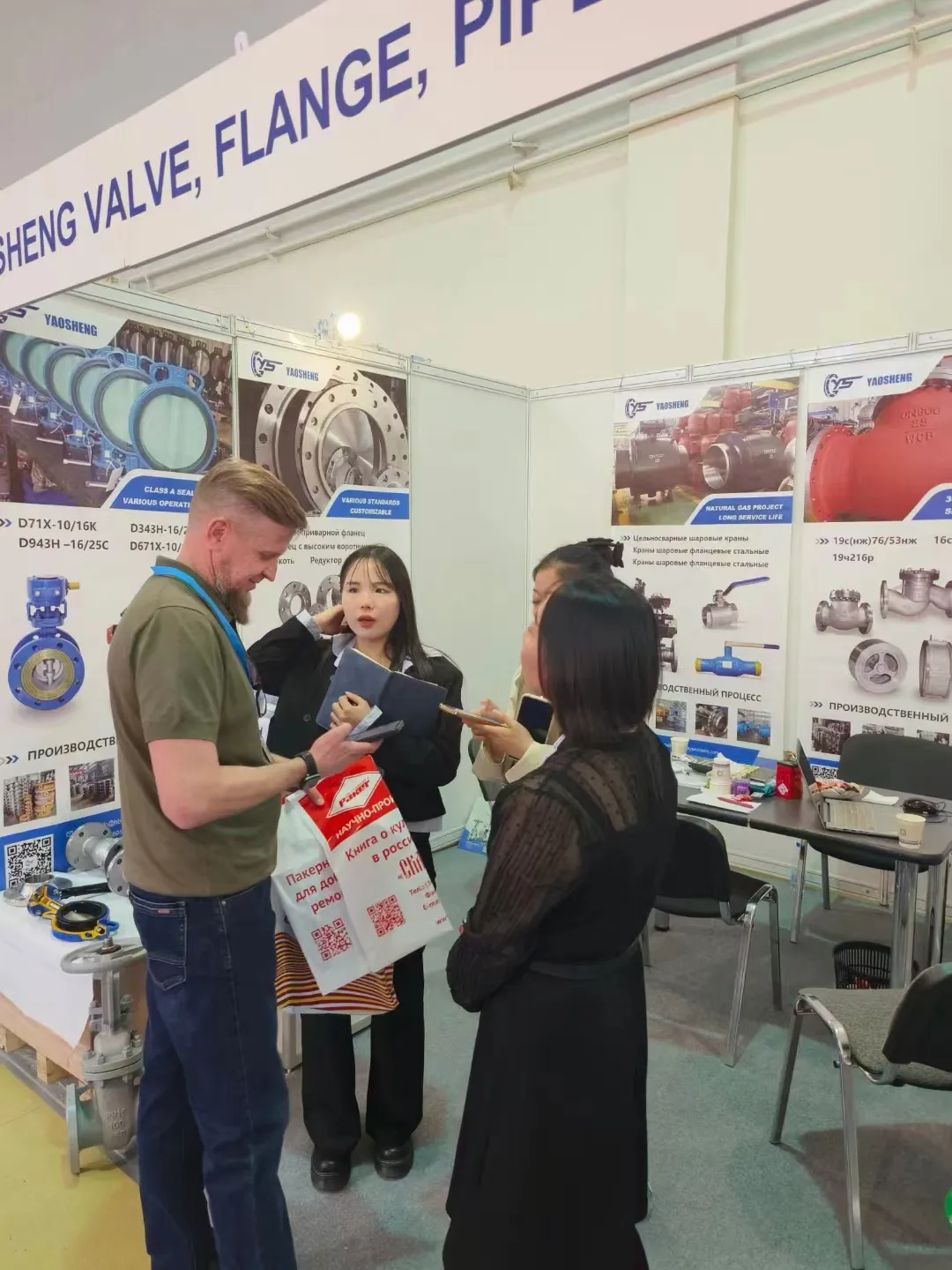

double flanged butterfly valve supplier

A reputable double flanged butterfly valve supplier often provides customization options to meet specific project requirements. This includes varied sizes, configurations, and materials tailored to particular applications. Additionally, established suppliers usually have experienced technical support teams that can assist customers with product selection, installation advice, and troubleshooting. This level of service is invaluable, especially for complex projects where technical expertise can enhance overall efficiency and performance.

Cost-Effectiveness

While it may be tempting to go for the cheapest option available in the market, investing in quality double flanged butterfly valves from a reliable supplier often proves to be more cost-effective in the long run. Cheaper alternatives may save money upfront but often lead to frequent replacements, repairs, and increased maintenance costs due to poor quality and performance. Ultimately, selecting a dependable supplier who offers high-quality products can lead to significant savings and better operational efficiency.

Availability and Delivery

Another crucial factor to consider when choosing a double flanged butterfly valve supplier is their ability to ensure timely delivery and availability of products. Delays in procurement can halt operations and lead to significant financial losses. Leading suppliers maintain adequate stock levels and efficient logistics operations to deliver products promptly, ensuring that projects progress smoothly.

Reputation and Customer Feedback

Before finalizing a supplier, it is advisable to research their reputation in the industry. Customer reviews and testimonials can provide valuable insights into the reliability and performance of the supplier's products. Companies that have a track record of satisfied customers are more likely to provide high-quality valves and excellent service.

Conclusion

The selection of a reliable double flanged butterfly valve supplier is crucial for the success of any fluid control system. By prioritizing quality standards, material durability, technical support, and customer reputation, project managers can significantly enhance the performance and reliability of their systems. Investing time in selecting the right supplier not only assures quality products but also leads to better operational efficiencies, reduced maintenance costs, and ultimately, a more successful project outcome.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025