فېۋرال . 19, 2025 10:40

Back to list

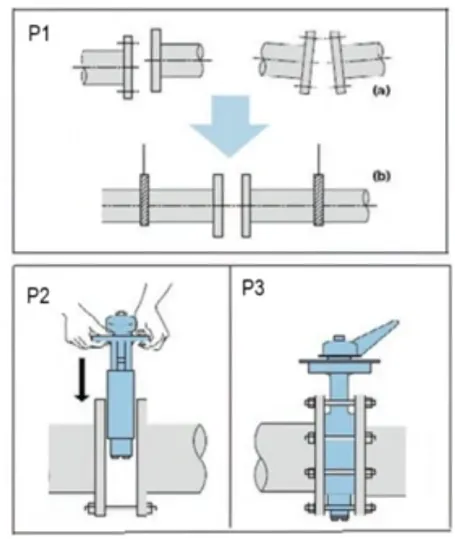

DP41X/F-10/16 Butterfly Balanced Valve

In the industrial world, precision and reliability are paramount, and the equipment chosen must stand up to these demands. Among the various solutions available for flow control, double flanged butterfly valves have emerged as a preferred choice across numerous sectors. Particularly in the vast landscape of industrial applications, Chinese double flanged butterfly valves have garnered attention due to their craftsmanship, state-of-the-art engineering, and adaptability to diverse operational environments.

Authority in manufacturing is evident through the numerous certifications and standards that these Chinese manufacturers adhere to. International standards such as ISO, API, and ANSI are commonly met (or even exceeded), reassuring customers of the product's reliability and safety. These credentials provide a significant competitive edge, making these valves desirable in global markets. Beyond the technical specifications, user trust is cultivated through comprehensive support and service platforms provided by Chinese suppliers. This includes detailed installation guides, maintenance tips, and troubleshooting advice, which are critical resources for ensuring optimal valve performance. In addition, most manufacturers offer warranties and after-sales service, cementing customer confidence in their purchase. Another compelling advantage of Chinese double flanged butterfly valves is their cost-effectiveness. While maintaining high standards of quality and durability, the efficient production methods and scale of operations allow these valves to be priced competitively. This affordability does not come at the cost of quality, but rather is a product of refined manufacturing processes and the economies of scale that Chinese factories are known for. In conclusion, choosing the right equipment is crucial for operational efficiency and safety in any industrial context. Chinese double flanged butterfly valves deliver on both counts, combining cutting-edge engineering with tried-and-true material science. Their wide applicability, coupled with the high standards of manufacturing, ensures that they meet the diverse needs of industries across the globe. For enterprises looking to optimize their fluid control systems without compromising on quality or reliability, these valves represent an optimal choice.

Authority in manufacturing is evident through the numerous certifications and standards that these Chinese manufacturers adhere to. International standards such as ISO, API, and ANSI are commonly met (or even exceeded), reassuring customers of the product's reliability and safety. These credentials provide a significant competitive edge, making these valves desirable in global markets. Beyond the technical specifications, user trust is cultivated through comprehensive support and service platforms provided by Chinese suppliers. This includes detailed installation guides, maintenance tips, and troubleshooting advice, which are critical resources for ensuring optimal valve performance. In addition, most manufacturers offer warranties and after-sales service, cementing customer confidence in their purchase. Another compelling advantage of Chinese double flanged butterfly valves is their cost-effectiveness. While maintaining high standards of quality and durability, the efficient production methods and scale of operations allow these valves to be priced competitively. This affordability does not come at the cost of quality, but rather is a product of refined manufacturing processes and the economies of scale that Chinese factories are known for. In conclusion, choosing the right equipment is crucial for operational efficiency and safety in any industrial context. Chinese double flanged butterfly valves deliver on both counts, combining cutting-edge engineering with tried-and-true material science. Their wide applicability, coupled with the high standards of manufacturing, ensures that they meet the diverse needs of industries across the globe. For enterprises looking to optimize their fluid control systems without compromising on quality or reliability, these valves represent an optimal choice.

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025