Січ . 13, 2025 15:29

Back to list

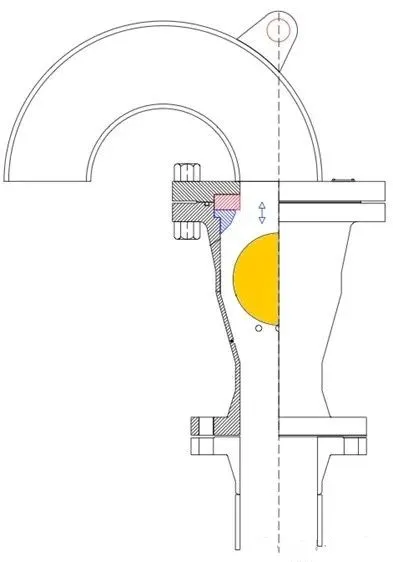

cast steel globe valve

In industrial applications where durability and reliability are paramount, the cast steel globe valve stands out as an indispensable asset. This robust component, expertly crafted using high-quality steel, is designed to control the flow of a variety of media, including liquids, gases, and steam, with precision and consistency. Its construction is pivotal for industries requiring seamless operational capabilities in high-temperature and high-pressure environments.

Real-world applications of cast steel globe valves underscore their reliability and efficiency. For instance, in a chemical plant, these valves are instrumental in handling aggressive fluids with precision, minimizing risks associated with leaks and contamination. Their robust design means they can handle rapidly changing conditions without compromising functionality. This reliability translates into decreased downtime and maintenance costs for businesses, bolstering trust in the product’s performance. Furthermore, the design of the cast steel globe valve allows for ease of maintenance and inspection, which is a crucial consideration for long-term operational efficiency. The accessibility of its components means that routine checks can be performed without the need for complete system shutdowns, ensuring continuous production and preventing costly interruptions. In summary, the cast steel globe valve is a testament to the blend of experience, expertise, authority, and trustworthiness that goes into industrial valve manufacturing. Its enduring presence and pivotal role in various industrial applications underscore its unparalleled status in facilitating precise flow control in harsh environments. Businesses seeking durable and reliable valve solutions can confidently rely on cast steel globe valves for their robust design and proven track record in performance excellence.

Real-world applications of cast steel globe valves underscore their reliability and efficiency. For instance, in a chemical plant, these valves are instrumental in handling aggressive fluids with precision, minimizing risks associated with leaks and contamination. Their robust design means they can handle rapidly changing conditions without compromising functionality. This reliability translates into decreased downtime and maintenance costs for businesses, bolstering trust in the product’s performance. Furthermore, the design of the cast steel globe valve allows for ease of maintenance and inspection, which is a crucial consideration for long-term operational efficiency. The accessibility of its components means that routine checks can be performed without the need for complete system shutdowns, ensuring continuous production and preventing costly interruptions. In summary, the cast steel globe valve is a testament to the blend of experience, expertise, authority, and trustworthiness that goes into industrial valve manufacturing. Its enduring presence and pivotal role in various industrial applications underscore its unparalleled status in facilitating precise flow control in harsh environments. Businesses seeking durable and reliable valve solutions can confidently rely on cast steel globe valves for their robust design and proven track record in performance excellence.

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025