Comparative Analysis of 8% Butterfly Valve Pricing in Today's Market

An In-Depth Look at 8% Butterfly Valve Pricing

When it comes to industrial applications, the importance of choosing the right valve cannot be overstated. Among various types of valves, the butterfly valve has gained immense popularity due to its compact design, lightweight nature, and significant flow control capabilities. The focus of this article will be on the pricing aspects of the 8% butterfly valve, exploring factors that influence its cost, market trends, and considerations for buyers.

Understanding Butterfly Valves

Butterfly valves are quarter-turn rotational valves that operate by turning a disc within the pipe. They are commonly used in throttling and isolation applications across industries such as water treatment, oil and gas, HVAC systems, and chemical processing. The term 8% butterfly valve typically refers to a specific type that is designed for particular performance metrics, likely involving flow coefficients or pressure drop percentages. However, when discussing the pricing of butterfly valves, especially those denoted with such specifications, a variety of factors come into play.

Factors Influencing Pricing

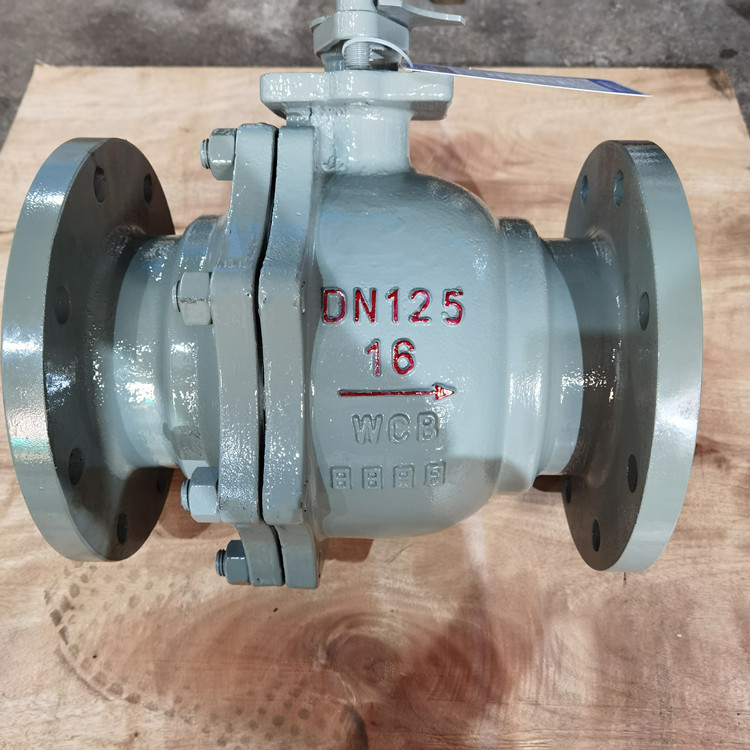

1. Material Composition The material from which a butterfly valve is made significantly impacts its price. Common materials include cast iron, stainless steel, and PVC. Stainless steel valves, known for their corrosion resistance and durability, tend to be on the higher end of the pricing spectrum whereas cast iron valves are generally more economical.

2. Size and Dimension The size of the butterfly valve directly affects its cost. Larger valves require more raw materials and are often subject to higher manufacturing and transportation costs. When estimating the price of an 8% butterfly valve, it’s essential to consider its diameter and the specific requirements of the application it is intended for.

3. End Connection Type Butterfly valves can be equipped with different types of end connections, including flanged, welded, or threaded ends. The complexity of the connection type can also influence pricing, with flanged connections typically costing more due to the associated machining and fabrication.

4. Operational Features Advanced features such as automatic actuators, positioners, and specialized seals can add to the overall price of butterfly valves. Valves designed for higher pressure ratings or exceptional temperature resistance will naturally command a higher price due to the enhanced engineering and materials involved.

8 butterfly valve price

5. Brand Reputation The manufacturer also plays a critical role in pricing. Established brands with a reputation for reliability often price their products at a premium. That said, they may also offer superior warranties and customer support, which can be valuable to long-term operations.

Market Trends

As industries continuously evolve, so do the trends in valve pricing. Currently, there is a noticeable increase in demand for energy-efficient and sustainable solutions in water and wastewater management. This shift has led to the development of eco-friendly butterfly valves, which are designed to minimize energy consumption during operation. Such innovations can initially result in higher prices, but they often lead to cost savings over time, making them an attractive option for many applications.

Additionally, fluctuations in raw material prices can create volatility in butterfly valve pricing. For example, recent market trends have seen significant changes in the costs of metals, which may lead to price adjustments for valves made of those materials. This makes it essential for buyers to stay informed about market conditions when planning purchases.

Considerations for Buyers

When it comes to purchasing an 8% butterfly valve, buyers must consider the total cost of ownership, which accounts for initial purchase prices, installation costs, maintenance, and potential operational savings. It is also prudent to engage in thorough research and comparison shopping, not just for pricing, but for quality and supplier reliability as well.

Another important consideration is the specific application requirements. Consulting with engineers or industry professionals can ensure that the selected valve type, size, and specifications meet both performance needs and budget constraints.

Conclusion

In summary, the pricing of an 8% butterfly valve is influenced by a myriad of factors including material, size, operational features, and market dynamics. Understanding these elements can help buyers make informed decisions that align with their technical and economic objectives. With the right approach, investing in butterfly valves can lead to improved efficiency and reliability in various industrial applications.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025