flanged check valve manufacturers

Flanged Check Valve Manufacturers Ensuring Quality and Reliability

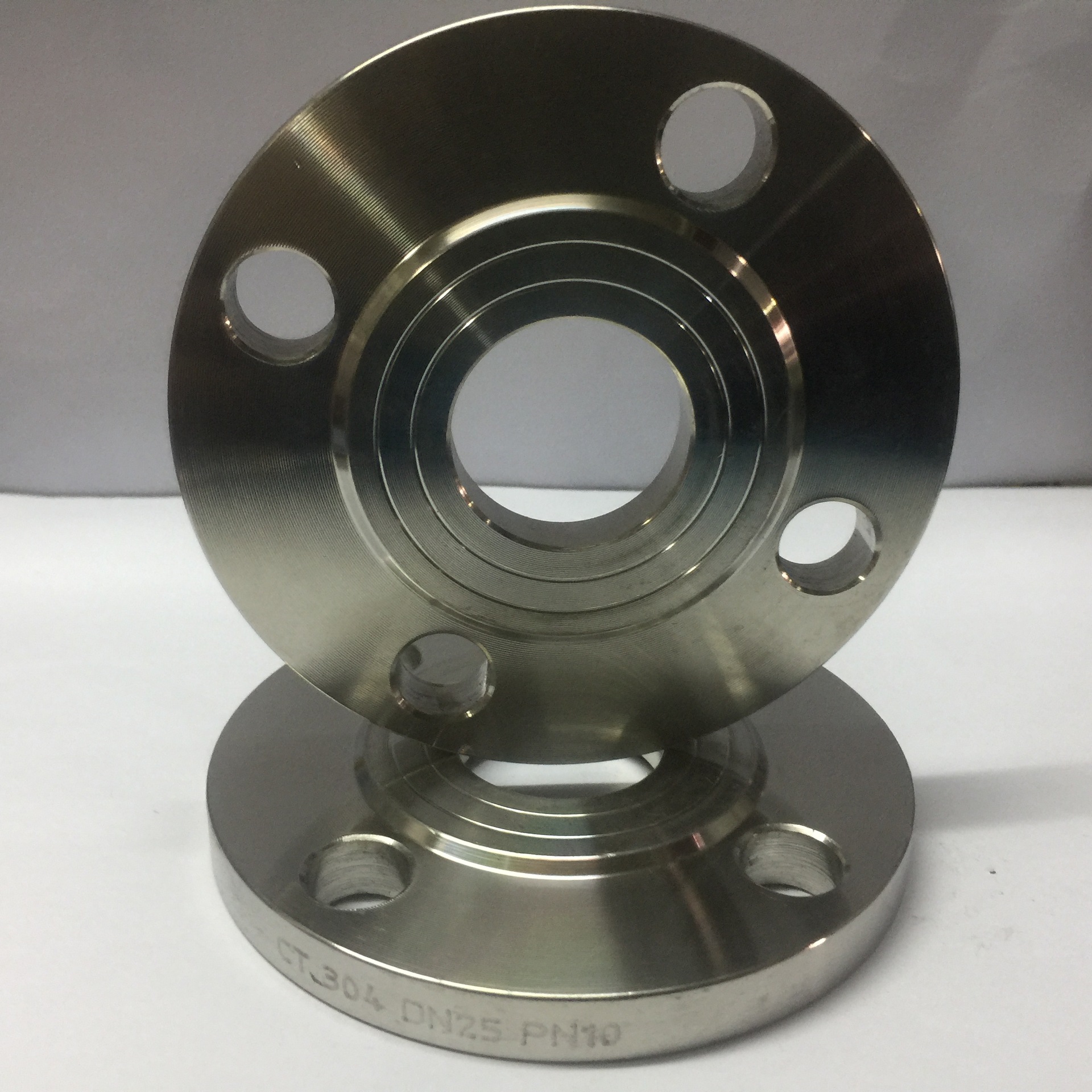

Flanged check valves are crucial components in various industrial applications, primarily used to prevent backflow in piping systems. They are designed with a flange connection, allowing for an easy and secure attachment to pipelines. As the demand for reliable and efficient fluid control solutions rises, flanged check valve manufacturers play a vital role in delivering products that meet industry standards and customer needs.

One of the main reasons industries rely heavily on flanged check valves is their ability to maintain directional flow. These valves are engineered to close automatically when the fluid flow reverses, thus protecting equipment and maintaining system integrity. Manufacturers of flanged check valves focus on various features, including the valve design, materials used, and the overall reliability of the product.

The manufacturing process of flanged check valves involves several steps. It begins with selecting high-quality raw materials, such as stainless steel, carbon steel, or other alloys, depending on the application and environment where the valve will be used. These materials are crucial because they need to withstand significant pressure, temperature variations, and corrosive elements present in certain fluids.

Moreover, leading flanged check valve manufacturers emphasize rigorous quality control throughout the production process. This includes testing for leaks, pressure ratings, and adherence to industry standards like ISO, API, and ASME. By ensuring that the valves can withstand the operational demands, manufacturers build trust and reliability with their clients, whether in oil and gas, water treatment, food processing, or chemical industries.

flanged check valve manufacturers

In addition to quality, customization is another significant aspect provided by flanged check valve manufacturers. As each industry has unique requirements, manufacturers often offer tailored solutions to meet specific needs. Customization can range from specific dimensions, materials, or even additional features such as built-in actuation systems. This flexibility allows businesses to integrate these valves seamlessly into their piping systems.

When selecting a flanged check valve manufacturer, it's essential to consider several factors. A reputable manufacturer will not only provide high-quality products but will also offer excellent customer support and guidance. This includes assisting clients in selecting the right type of check valve for their specific applications. Additionally, manufacturers should be able to provide technical specifications and installation instructions to ensure a smooth integration into existing systems.

Furthermore, sustainability is becoming increasingly important in the manufacturing sector. Many flanged check valve manufacturers are adopting eco-friendly practices by utilizing recyclable materials and reducing waste during production. This commitment to sustainability not only appeals to environmentally conscious consumers but also ensures compliance with global environmental regulations.

As technology evolves, flanged check valve manufacturers are also incorporating advanced features into their products. This includes the integration of smart technology that allows for monitoring and control of valve performance remotely. These innovations lead to improved operational efficiency and better maintenance practices, ultimately reducing downtime and costs for industries.

In conclusion, flanged check valve manufacturers are pivotal in providing essential components for fluid control systems across various sectors. Their commitment to quality, customization, and sustainability ensures that industries receive reliable solutions tailored to their specific needs. As the landscape of industrial operations continues to evolve, these manufacturers will play an increasingly integral role in maintaining efficiency and safety in fluid management processes. Choosing the right manufacturer can significantly impact the reliability and performance of piping systems, making it imperative for industries to partner with trusted and innovative suppliers.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025