Top Manufacturers of High-Quality Ball Valves for Various Industrial Applications

Understanding Ball Valve Manufacturers A Comprehensive Overview

Ball valves are crucial components in various industrial applications, providing excellent control over the flow of liquids and gases. With their simple yet effective design, they are widely used in sectors such as oil and gas, water treatment, and chemical processing. As the demand for reliable valves increases, identifying reputable ball valve manufacturers becomes essential for businesses looking to optimize efficiency and safety. This article delves into the key aspects of ball valve manufacturers, focusing on what makes them stand out in the industry.

The Importance of Ball Valve Manufacturers

Ball valves are favored in many applications due to their ability to provide tight sealing and quick shut-off capabilities. These attributes play a significant role in maintaining the integrity of systems, reducing the risk of leaks and failures. Consequently, choosing the right manufacturer is vital to ensure that the valves meet industry standards and specifications. A reputable manufacturer will consider factors such as material quality, design, and compliance with international codes.

Key Features of Quality Ball Valve Manufacturers

1. Material Selection Quality ball valve manufacturers use high-grade materials, such as stainless steel, brass, and PVC, to produce valves that are durable and resistant to corrosion. The choice of material impacts the valve’s performance, longevity, and suitability for specific applications. Manufacturers must understand the requirements of their target industries to select materials that perform well under varying temperature and pressure conditions.

2. Expertise and Experience Established manufacturers bring a wealth of experience to the table. Their expertise in valve design and production allows for better innovation and adaptation to industry needs. A manufacturer with a long-standing reputation is likely to have the technical know-how to produce valves that not only meet but exceed customers' expectations.

3. Quality Control and Testing Rigorous quality control processes are a hallmark of reputable ball valve manufacturers. From the initial design to the final testing phase, each valve undergoes thorough examination to ensure it performs flawlessly. This may include hydrostatic testing, pressure testing, and performance assessments. Manufacturers who adhere to international quality standards, such as ISO 9001, are often more reliable, as they commit to maintaining consistency in their products.

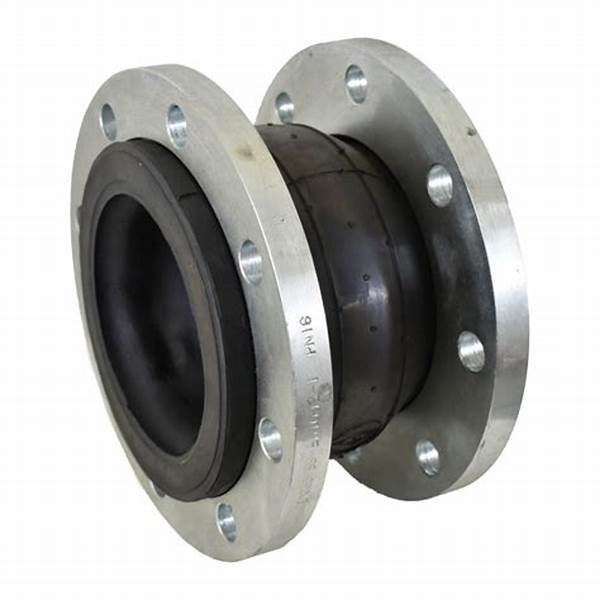

ball valve 3 manufacturer

4. Customization Options Different applications may require customized valves. Leading manufacturers often offer bespoke solutions tailored to specific customer needs. This includes the option to design valves with unique dimensions, materials, and functionalities. A manufacturer that provides customization services demonstrates flexibility and a customer-centric approach.

The Role of Technology in Manufacturing

Modern ball valve manufacturers increasingly rely on cutting-edge technology to enhance productivity and precision in their manufacturing processes. Computer-aided design (CAD) software allows engineers to simulate and modify valve designs before production, reducing errors and saving time. Additionally, advanced manufacturing techniques, such as CNC machining and 3D printing, enable manufacturers to produce complex designs with exceptional accuracy.

Sustainable Practices in Ball Valve Manufacturing

As industries strive for sustainability, leading ball valve manufacturers are adopting eco-friendly practices. This includes using recyclable materials, minimizing waste during production, and implementing energy-efficient machining processes. By prioritizing sustainability, manufacturers not only comply with environmental regulations but also appeal to environmentally conscious customers and markets.

Conclusion

Choosing the right ball valve manufacturer is paramount for any business seeking reliable, high-performance valves. Factors such as material selection, expertise, quality control, customization options, and technological innovation play critical roles in determining a manufacturer's reputation. As industries evolve and demands change, the best manufacturers will adapt by embracing sustainable practices and advanced technologies, ensuring they continue to meet the needs of their customers. By understanding these key aspects, businesses can make informed decisions that contribute to their operational success and safety.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025