Wholesale Low Pressure Check Valves | Reliable and Affordable Solutions

Understanding Wholesale Check Valves for Low Pressure Applications

Check valves, often referred to as non-return valves, play a crucial role in various piping systems, especially in applications involving low pressure. They allow fluid to flow in one direction while preventing backflow, ensuring efficiency and safety in various industrial processes. This article explores the significance of wholesale check valves designed for low-pressure applications, detailing their features, benefits, and considerations for procurement.

What are Check Valves?

Check valves are simple yet effective devices that automatically prevent backflow in piping systems. They operate based on the pressure difference between the upstream and downstream sides. When fluid flows in the designated direction, the check valve opens; conversely, if the flow reverses, the valve closes, preventing any backflow. This mechanism is vital for maintaining the integrity of the system and protecting equipment from potential damage caused by reverse flow.

Key Features of Low Pressure Check Valves

When discussing check valves for low pressure applications, several key features come to the forefront

1. Material Compatibility Low pressure check valves are typically made from materials like PVC, brass, or stainless steel, depending on the application. It's crucial to choose a material compatible with the fluids being handled.

2. Size and Design Available in various sizes, these valves can be tailored to fit specific piping requirements. Their design often promotes fluid dynamics, ensuring minimal pressure drop and efficient flow.

3. Spring-Loaded Mechanism Many low pressure check valves incorporate a spring mechanism that helps the valve close more quickly, enhancing performance in systems where slight pressure fluctuations are common.

4. Ease of Maintenance Wholesale options often come with features that ensure easy maintenance and replacement, reducing downtime and operational costs.

Benefits of Wholesale Procurement

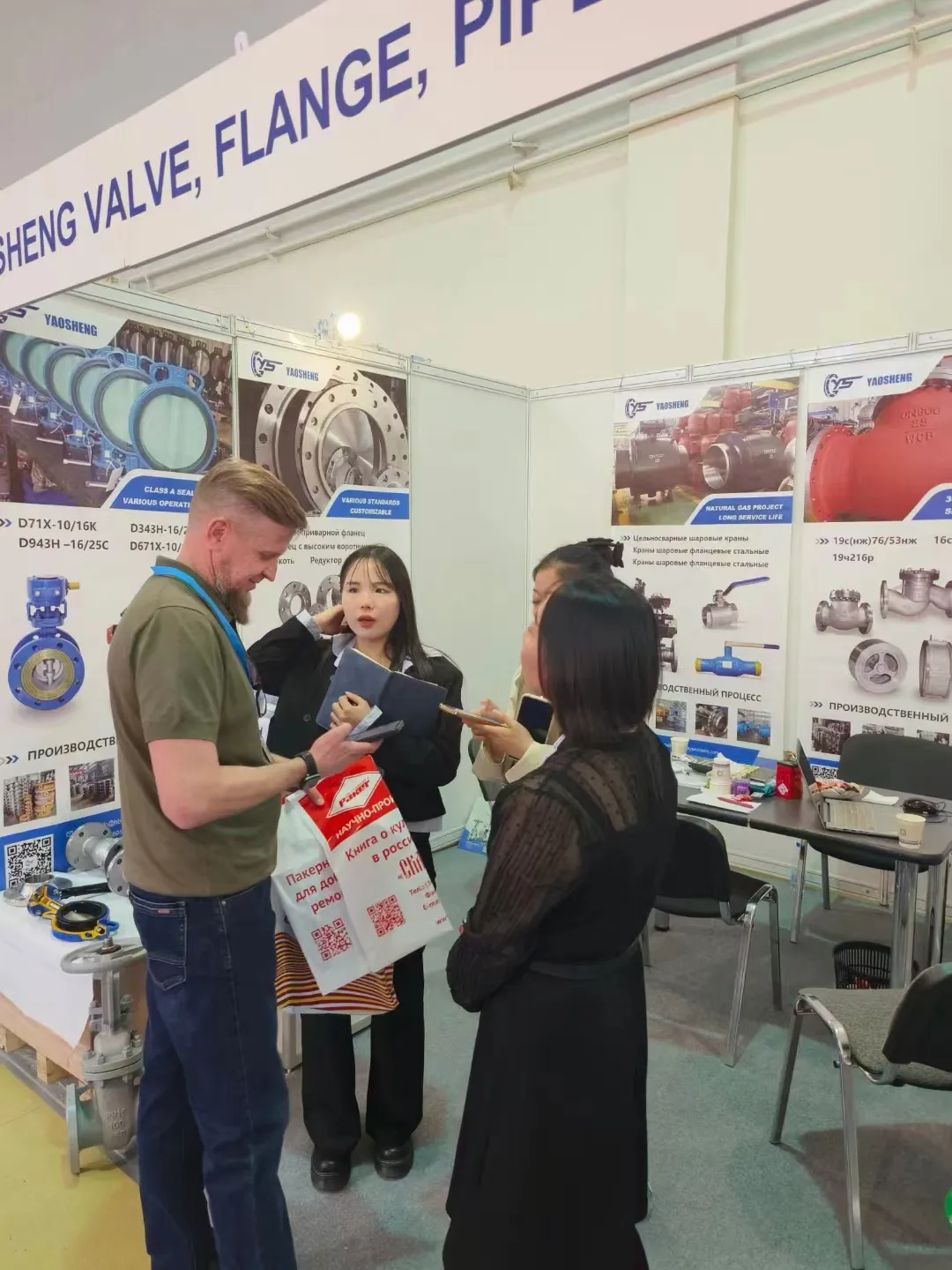

wholesale check valves low pressure

Purchasing check valves in wholesale quantities can lead to significant benefits for businesses

1. Cost Efficiency Buying in bulk often results in lower cost per unit, aiding budget management for projects requiring multiple valves.

2. Consistency in Supply Securing a wholesale agreement ensures a consistent supply of products, which is particularly beneficial for companies with ongoing projects or regular requirements.

3. Access to Varied Options Wholesale suppliers often offer a wide range of options, enabling businesses to select the perfect fit for their specific applications without sacrificing quality or performance.

Considerations Before Purchase

Before acquiring wholesale check valves for low pressure systems, consider the following

- Application Requirements Clearly define the requirements of your application, including pressure ratings and fluid characteristics.

- Supplier Reputation Choose reputable suppliers with a history of providing high-quality check valves. Reviews and referrals can provide insights into reliability.

- Standards Compliance Ensure that the check valves meet relevant industry standards for safety and performance.

Conclusion

Wholesale check valves for low pressure applications are essential components in many fluid handling systems. Their ability to prevent backflow while maintaining flow efficiency makes them invaluable in various industries. By understanding the features, benefits, and procurement considerations, businesses can make informed decisions, ensuring operational success and enhanced system reliability.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025