ጥር . 20, 2025 09:03

Back to list

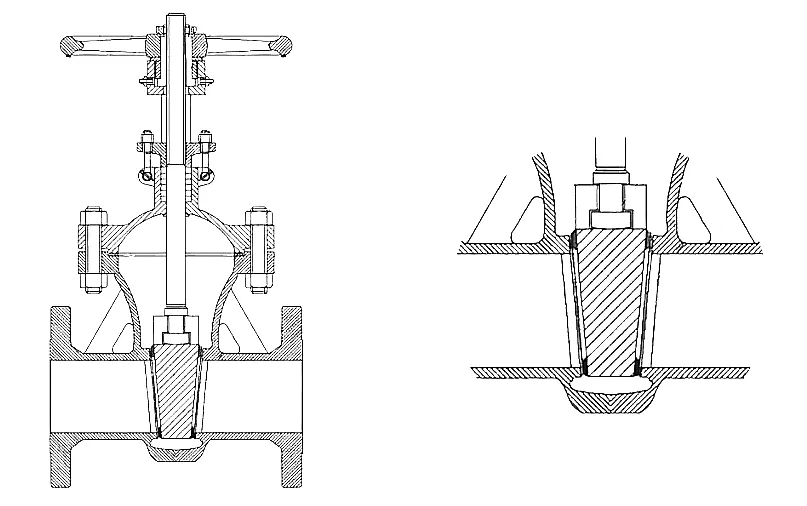

flanged gate valves

Flanged gate valves are critical components in various industries, including oil and gas, water treatment, power generation, and chemical processing. These valves are designed to control the flow of liquid through pipelines by lifting a gate out of the path of the fluid. What sets flanged gate valves apart is their flanged ends, which provide enhanced sealing capabilities and ease of maintenance. This article explores the unique advantages of flanged gate valves and how they meet the highest standards of reliability and performance.

When it comes to installation and maintenance, flanged gate valves offer unique advantages over their threaded or welded counterparts. The use of flanges means that these valves can be removed from the pipeline without needing to cut or weld the pipes, significantly reducing downtime and labor costs during maintenance or replacement procedures. Additionally, the sealing mechanism inherent in flange connections provides a robust and leak-proof joint. One must consider the specific application to determine the optimal configuration of a flanged gate valve. Factors such as the type and velocity of the fluid, pipeline pressure, and required flow control precision influence the choice between rising and non-rising stem designs, different body materials, and actuator types. Consulting with valve specialists and leveraging their expertise can ensure the selection of the most suitable valve configuration, enhancing operational efficiency and longevity. Despite their many advantages, it is important to note that flanged gate valves do have limitations that need to be addressed. For instance, they are generally not recommended for use in throttling applications, where precise flow control is necessary. The gate's perpendicular movement can cause wear and tear, leading to potential leakage or compromised performance over time. Therefore, it is vital to apply these valves in scenarios where they best align with their intended purpose – as on/off or isolation valves. In conclusion, flanged gate valves are invaluable assets in industries where robust flow control solutions are required. Their design facilitates low fluid resistance, ease of maintenance, and adaptability to various materials and standards. The compliance with stringent industry certifications further establishes their authority and reliability. For industry professionals prioritizing efficient pipeline management, flanged gate valves offer unparalleled experience and trustworthiness without sacrificing functionality. Understanding their capabilities and limitations allows for informed decision-making and optimal system design, ensuring seamless operations across various industrial applications.

When it comes to installation and maintenance, flanged gate valves offer unique advantages over their threaded or welded counterparts. The use of flanges means that these valves can be removed from the pipeline without needing to cut or weld the pipes, significantly reducing downtime and labor costs during maintenance or replacement procedures. Additionally, the sealing mechanism inherent in flange connections provides a robust and leak-proof joint. One must consider the specific application to determine the optimal configuration of a flanged gate valve. Factors such as the type and velocity of the fluid, pipeline pressure, and required flow control precision influence the choice between rising and non-rising stem designs, different body materials, and actuator types. Consulting with valve specialists and leveraging their expertise can ensure the selection of the most suitable valve configuration, enhancing operational efficiency and longevity. Despite their many advantages, it is important to note that flanged gate valves do have limitations that need to be addressed. For instance, they are generally not recommended for use in throttling applications, where precise flow control is necessary. The gate's perpendicular movement can cause wear and tear, leading to potential leakage or compromised performance over time. Therefore, it is vital to apply these valves in scenarios where they best align with their intended purpose – as on/off or isolation valves. In conclusion, flanged gate valves are invaluable assets in industries where robust flow control solutions are required. Their design facilitates low fluid resistance, ease of maintenance, and adaptability to various materials and standards. The compliance with stringent industry certifications further establishes their authority and reliability. For industry professionals prioritizing efficient pipeline management, flanged gate valves offer unparalleled experience and trustworthiness without sacrificing functionality. Understanding their capabilities and limitations allows for informed decision-making and optimal system design, ensuring seamless operations across various industrial applications.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025