feb . 13, 2025 22:23

Back to list

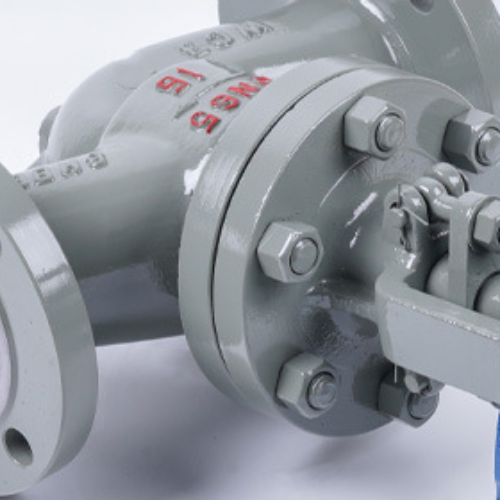

2 way needle valve

A two-way needle valve is an essential component in fluid control systems, known for its precision and reliability in regulating fluid flow rates. Used extensively across industries such as oil and gas, chemical processing, and pharmaceuticals, a two-way needle valve stands out for its ability to provide precise flow control, an attribute critical to optimizing operational efficiency and maintaining safety standards.

Trustworthiness is another pillar anchoring the reputation of two-way needle valves. In industries where precision and safety are paramount, these valves must demonstrate reliability over extended periods. Trust is built through a proven track record of performance, often illustrated through industry testimonials and case studies. Establishing this trust involves a commitment from manufacturers to provide comprehensive support services, such as installation guidance, maintenance tips, and readily available spare parts, ensuring minimal downtime for end users. The experience of using a two-way needle valve is enhanced by intuitive operation and maintenance. Whether installed in a complex automation system or a manual setup, the valve's user-friendly interface, typically featuring an easy-to-turn knob and clear scale indicator, ensures simple, precise adjustments. Maintenance is generally straightforward, involving routine checks and cleaning to prevent buildup of residues that might affect function. With proper care, these valves can function optimally across a wide temperature and pressure range, ensuring a dependable performance that users can count on. Incorporating modern advancements, many two-way needle valves now come equipped with smart technology integrations. These features allow for remote operation, monitoring, and adjustments, catering to the increasing demand for automation in industrial processes. This modern twist on a classic design not only boosts efficiency but also serves to further solidify the valve's standing as a cornerstone in fluid management systems. Selecting the right two-way needle valve requires balancing several factors, including pressure and temperature ratings, material compatibility, and flow characteristics specific to the application's requirements. For any business invested in fluid handling, prioritizing high-quality, expertly designed valves is a step towards optimizing both performance and safety, eventually securing operational longevity and success in competitive markets.

Trustworthiness is another pillar anchoring the reputation of two-way needle valves. In industries where precision and safety are paramount, these valves must demonstrate reliability over extended periods. Trust is built through a proven track record of performance, often illustrated through industry testimonials and case studies. Establishing this trust involves a commitment from manufacturers to provide comprehensive support services, such as installation guidance, maintenance tips, and readily available spare parts, ensuring minimal downtime for end users. The experience of using a two-way needle valve is enhanced by intuitive operation and maintenance. Whether installed in a complex automation system or a manual setup, the valve's user-friendly interface, typically featuring an easy-to-turn knob and clear scale indicator, ensures simple, precise adjustments. Maintenance is generally straightforward, involving routine checks and cleaning to prevent buildup of residues that might affect function. With proper care, these valves can function optimally across a wide temperature and pressure range, ensuring a dependable performance that users can count on. Incorporating modern advancements, many two-way needle valves now come equipped with smart technology integrations. These features allow for remote operation, monitoring, and adjustments, catering to the increasing demand for automation in industrial processes. This modern twist on a classic design not only boosts efficiency but also serves to further solidify the valve's standing as a cornerstone in fluid management systems. Selecting the right two-way needle valve requires balancing several factors, including pressure and temperature ratings, material compatibility, and flow characteristics specific to the application's requirements. For any business invested in fluid handling, prioritizing high-quality, expertly designed valves is a step towards optimizing both performance and safety, eventually securing operational longevity and success in competitive markets.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025