PRODUCT PARAMETERS:

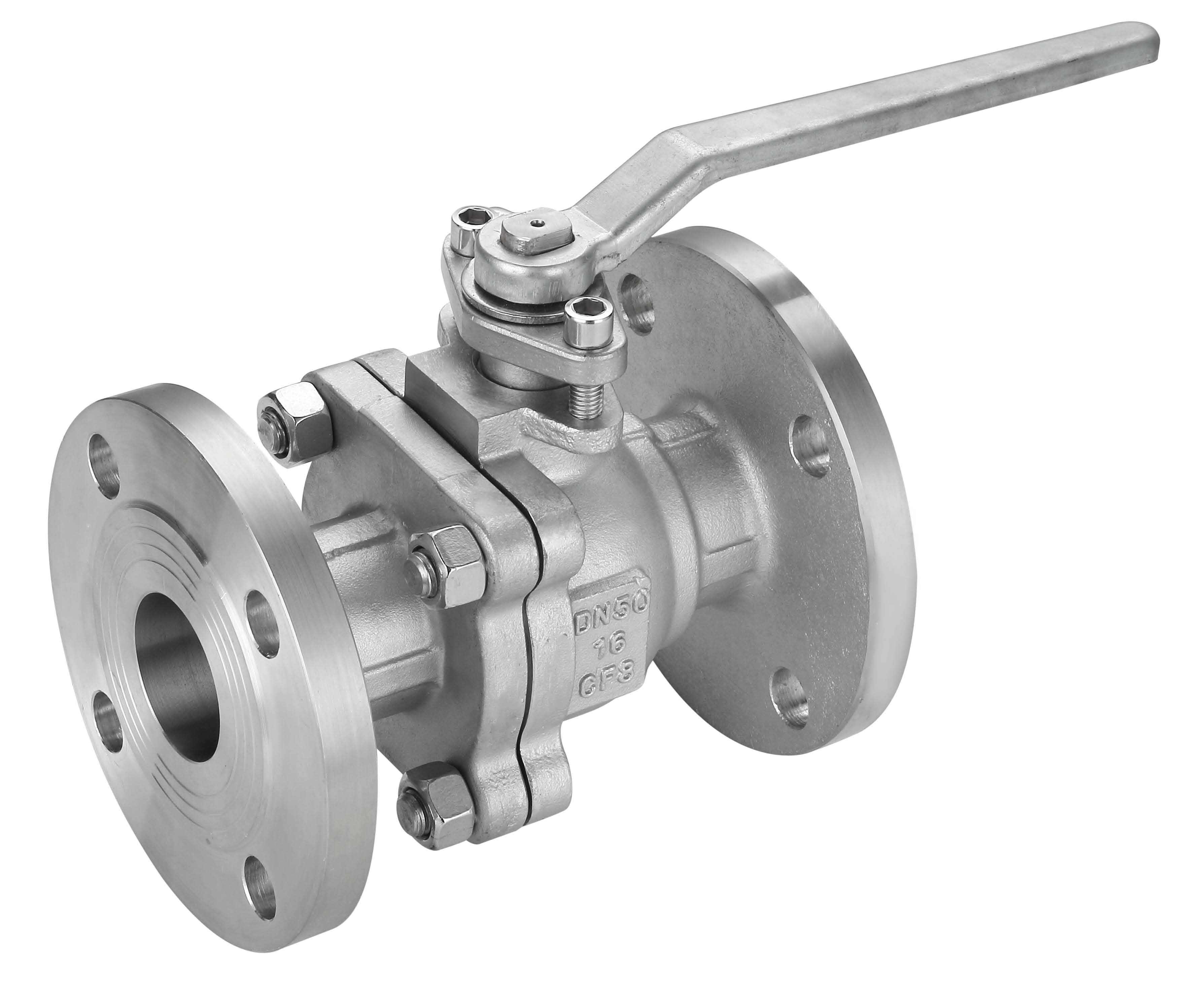

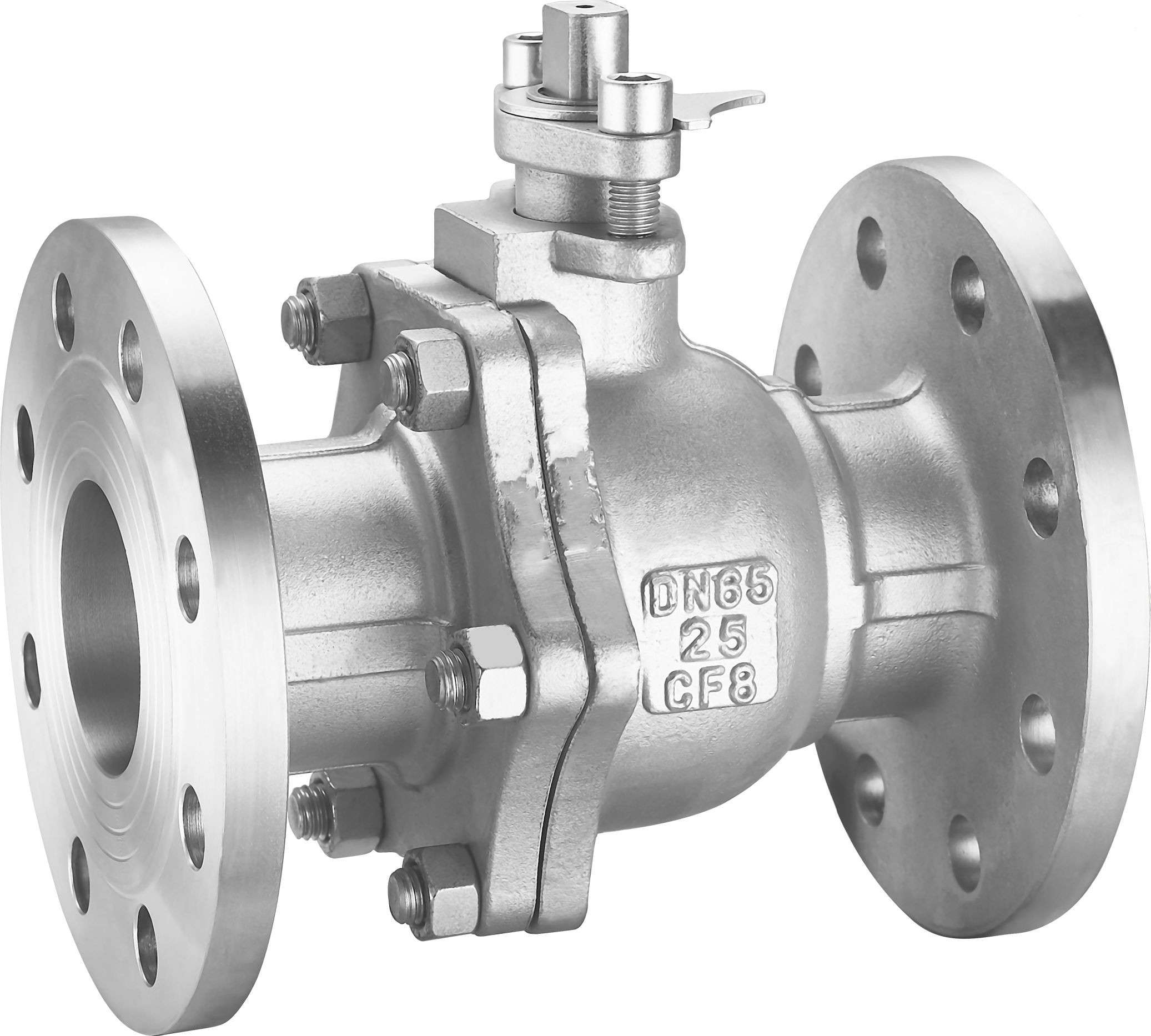

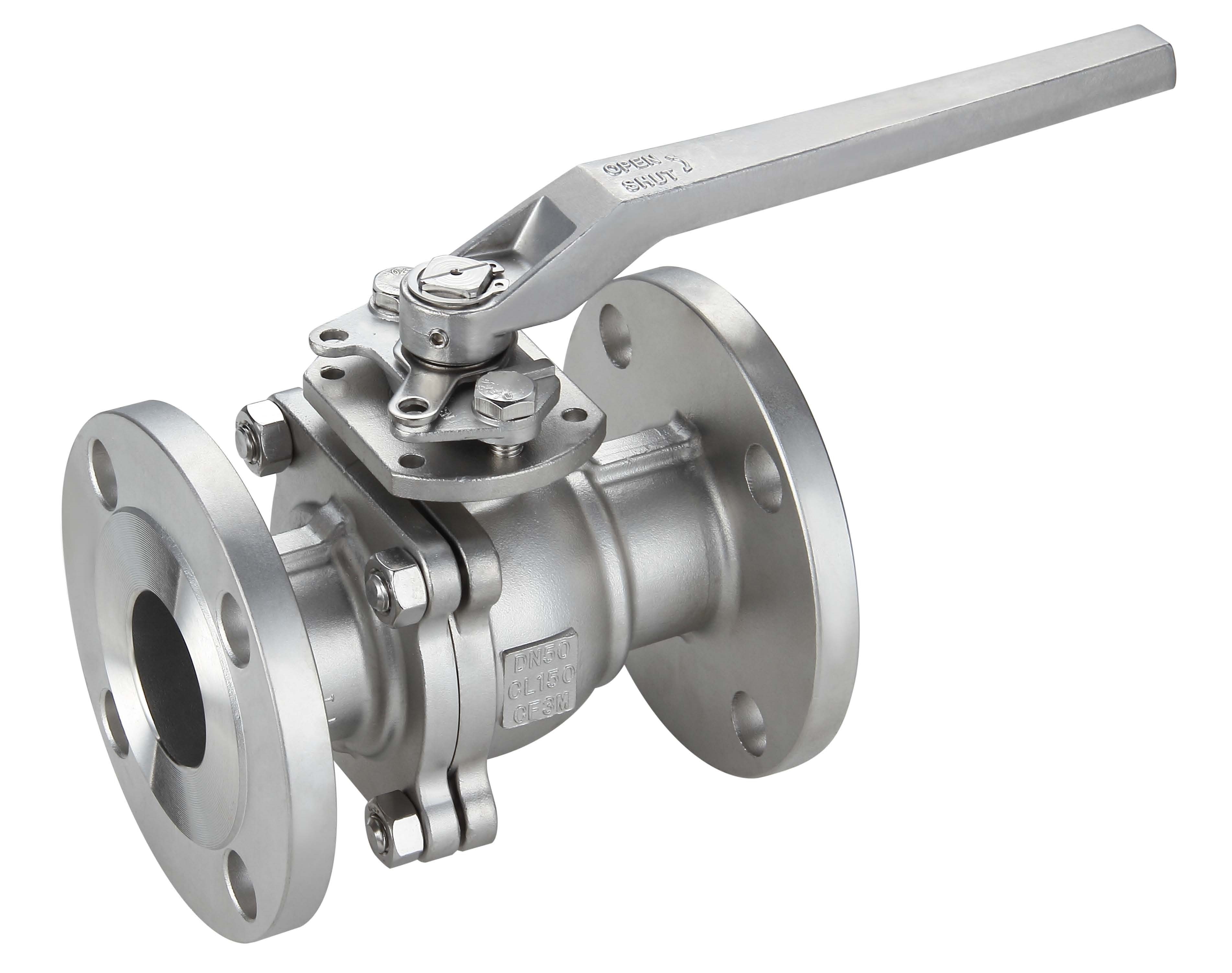

ANSI Floating Ball Valve Materiaal fan wichtichste dielen

|

ANSI Floating Ball Valve Materiaal fan wichtichste dielen |

|

|

Part Namme |

materiaal |

|

Body / motorkap |

ASTM A216 WCB, CF8, CF8M |

|

bal |

ASTM A105, F304, F316 |

|

Valve stem |

ASTM A182 F6a, F304, F316 |

|

Gasket |

PTFE |

ANSI Floating Ball Valve Q41F prestaasjes spesifikaasjes

|

ANSI Floating Ball Valve Q41F prestaasjes spesifikaasjes |

|||||

|

model |

Nominale druk |

Testdruk (mpa) wetter |

goede temperatuer |

Tapaslik medium |

|

|

sterkte |

segel |

||||

|

Q41F-150LB |

150 |

3.00 |

2.20 |

≤150 ℃ |

Wetter, stoom, oalje, ensfh. |

|

Q41F-300LB |

300 |

7.50 |

5.50 |

||

|

Q41F-600LB |

600 |

15.00 |

11.00 |

||

ANSI driuwende bal fentyl Q41F ôfmjittings en ferbining ôfmjittings

|

ANSI driuwende bal fentyl Q41F ôfmjittings en ferbining ôfmjittings |

|||||||

|

model |

Nominale diameter |

Grutte (mm) |

|||||

|

L |

D |

D1 |

D2 |

bf |

z-φd |

||

|

Q41F-150LB |

1/2 " |

108 |

90 |

60.5 |

35 |

11-2 |

4 * φ16 |

|

3/4 " |

117 |

100 |

70 |

43 |

13.5-2 |

4 * φ16 |

|

|

1" |

127 |

110 |

79.5 |

51 |

15-2 |

4 * φ16 |

|

|

1 1/4 " |

140 |

115 |

89 |

63.5 |

16.5-2 |

4 * φ16 |

|

|

1 1/2 " |

165 |

125 |

98.5 |

73 |

18-2 |

4 * φ16 |

|

|

2" |

178 |

150 |

121 |

92 |

19.5-2 |

4 * φ19 |

|

|

2 1/2 " |

190 |

180 |

140 |

105 |

23-2 |

4 * φ19 |

|

|

3 " |

203 |

190 |

152.5 |

127 |

24.5-2 |

4 * φ19 |

|

|

4 " |

229 |

230 |

190.5 |

157 |

24.5-2 |

8 * φ19 |

|

|

6 " |

394 |

280 |

241.5 |

216 |

26-2 |

8 * φ22 |

|

|

8" |

457 |

345 |

298.5 |

270 |

29-2 |

8 * φ22 |

|

|

Q41F-300LB |

1/2 " |

140 |

95 |

66.5 |

35 |

15-2 |

4 * φ16 |

|

3/4 " |

152 |

115 |

82.5 |

43 |

16.5-2 |

4 * φ19 |

|

|

1" |

165 |

125 |

89 |

51 |

18-2 |

4 * φ19 |

|

|

1 1/4 " |

178 |

135 |

98.5 |

63.5 |

19.5-2 |

4 * φ19 |

|

|

1 1/2 " |

190 |

155 |

114.5 |

73 |

21-2 |

4 * φ22 |

|

|

2" |

216 |

165 |

127 |

92 |

23-2 |

8 * φ19 |

|

|

2 1/2 " |

241 |

190 |

149 |

105 |

26-2 |

8 * φ22 |

|

|

3 " |

282 |

210 |

168.5 |

127 |

29-2 |

8 * φ22 |

|

|

4 " |

305 |

255 |

200 |

157 |

32-2 |

8 * φ22 |

|

|

6 " |

403 |

320 |

270 |

216 |

37-2 |

12 * φ22 |

|

|

8" |

502 |

380 |

330 |

270 |

42-2 |

12 * φ25 |

|

Oanfraach:

Dit fentyl is geskikt foar alle soarten pipelines dy't folslein iepen en folslein sluten binne, net foar throttling.

Foardielen fan it bedriuw:

-

1.Wy binne fabrikant Sûnt 1992.

1.Wy binne fabrikant Sûnt 1992. -

2.CE, API, ISO goedkard.

2.CE, API, ISO goedkard. -

3.Fast levering.

3.Fast levering. -

4.Low priis mei hege kwaliteit.

4.Low priis mei hege kwaliteit. -

5.Profesjoneel wurk Team!

5.Profesjoneel wurk Team!

Produkt foardielen:

1.We hawwe Sand of Precision casting technology, Sa kinne wy as jo tekenjen ûntwerp en produksje.

2.Customers 'logo's binne beskikber cast op it fentyl lichem.

3. Al ús casting mei tempering proseduere foar Processing.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding

6. Every valve must be tested before delivery from the factory, only qualified onescanbe shipped.

7.De soarte fentyl brûke wy normaal Houten gefallen om te pakken, Wy kinne ek neffens

spesifike klant oanfragen.