Gearr . 01, 2025 05:11

Back to list

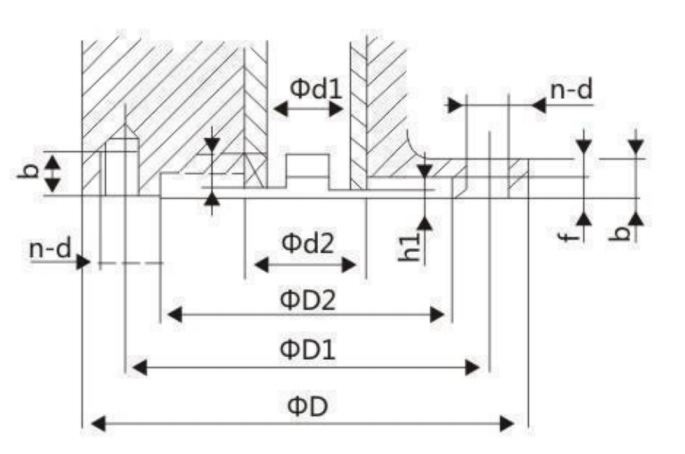

D71X-10 10Q 16 16Q Wafer Centerline Butterfly Valve

In the intricate world of industrial plumbing and fluid management, the ball valve stands as an unsung hero, particularly when discussing the ball valve 3. This specific type of valve plays an essential role in a myriad of applications, ranging from domestic piping systems to heavy-duty industrial processes. Its unique design and functionality not only make it a preferred choice among engineers and technicians but also an indispensable component in many sectors.

In the realm of trustworthiness, the ball valve 3 commands significant respect. Its durability has been tested repeatedly in various settings, confirming its high performance and reliability. Regular users often report a longer lifespan for these valves, credited to their sturdy build and minimal need for frequent replacements. Moreover, the design reduces the risk of leakage and mechanical failure — critical factors in applications where interruptions can lead to costly downtimes or safety hazards. In practical use, ball valve 3s are found in settings that demand rigorous flow control and ensure tight closures even in low-pressure scenarios. Their operation requires little torque, and with the option for automation, these valves can be integrated into sophisticated control systems that optimize workflow and increase the efficiency of the entire network. Despite their many advantages, selecting the right ball valve involves careful consideration of factors like pressure ratings, temperature range, and media type. For optimal use, consultation with a certified expert or manufacturer is advisable to match the ball valve 3 with the specific application’s requirements. Manufacturers of ball valve 3s often provide detailed specifications and operational guidelines that can empower users to make informed decisions. Given the global reliance on moving fluids safely and efficiently, the demand for reliable components like the ball valve 3 continues to rise. Therefore, investing in a high-quality valve not only ensures compliance and operational safety but also enhances overall system performance. In conclusion, whether used in a small-scale setting or a large industrial complex, the ball valve 3 remains a cornerstone of fluid management solutions. Its ability to provide precise control, coupled with its robust construction and compliance with industry standards, makes it a reliable choice across many sectors. Leveraging its full potential not only secures operational success but also informs better practices for fluid dynamics worldwide.

In the realm of trustworthiness, the ball valve 3 commands significant respect. Its durability has been tested repeatedly in various settings, confirming its high performance and reliability. Regular users often report a longer lifespan for these valves, credited to their sturdy build and minimal need for frequent replacements. Moreover, the design reduces the risk of leakage and mechanical failure — critical factors in applications where interruptions can lead to costly downtimes or safety hazards. In practical use, ball valve 3s are found in settings that demand rigorous flow control and ensure tight closures even in low-pressure scenarios. Their operation requires little torque, and with the option for automation, these valves can be integrated into sophisticated control systems that optimize workflow and increase the efficiency of the entire network. Despite their many advantages, selecting the right ball valve involves careful consideration of factors like pressure ratings, temperature range, and media type. For optimal use, consultation with a certified expert or manufacturer is advisable to match the ball valve 3 with the specific application’s requirements. Manufacturers of ball valve 3s often provide detailed specifications and operational guidelines that can empower users to make informed decisions. Given the global reliance on moving fluids safely and efficiently, the demand for reliable components like the ball valve 3 continues to rise. Therefore, investing in a high-quality valve not only ensures compliance and operational safety but also enhances overall system performance. In conclusion, whether used in a small-scale setting or a large industrial complex, the ball valve 3 remains a cornerstone of fluid management solutions. Its ability to provide precise control, coupled with its robust construction and compliance with industry standards, makes it a reliable choice across many sectors. Leveraging its full potential not only secures operational success but also informs better practices for fluid dynamics worldwide.

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025