NA PALAPALA HUA:

| inoa hapa | Mea waiwai | |||

| Kino / pāpale | CF8/CF3/CF8M/CF3M | |||

| pani pani | CF8/CF3/CF8M/CF3M | |||

| Hoʻopaʻa | Flexible graphite+304、PTFE | |||

| Hex nuts | 45 35CRMoA、25CR2MoV、 0CR18NI9 0CR17NI12MO2 |

|||

| Stud | 35CRMoA、25CR2Mo2、 0CR18NI9 0CRL17NI12MO2 |

|||

Application: It is widely used in pipelines under various working conditions, such as petrochemical, pharmaceutical, fertilizer, and power industries, to prevent the medium from flowing backward.

| Stainless Steel Lifting Check Valve Performance specifications | |||||||||

| kumu hoʻohālike | Pumi inoa (LB) |

ho'āʻo kaomi(mpa)) | wela kūpono | ʻAno kūpono | |||||

| ikaika | sila | ||||||||

| H41W-16P | 1.6 | 2.40 | 1.80 | ≤425℃ | Water, steam, petroleum, nitric acid, acetic acid, etc. | ||||

| H41W-25P | 2.5 | 3.75 | 2.75 | ||||||

| H41W-40P | 4.0 | 6.00 | 4.40 | ||||||

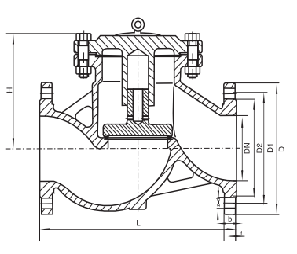

| Stainless Steel Lifting Check Valve Dimensions and connection dimensions | |||||||||

| kumu hoʻohālike | Anawaena inoa inoa (mm) |

nui (mm) | |||||||

| L | D | D1 | D2 | b | z-φd H1 |

||||

| H41W-16P | 15 | 130 | 95 | 65 | 45 | 14 | 4*φ14 | ||

| 20 | 150 | 105 | 75 | 55 | 14 | 4*φ14 | |||

| 25 | 160 | 115 | 85 | 65 | 14 | 4*φ14 | |||

| 32 | 180 | 135 | 100 | 78 | 16 | 4*φ18 | |||

| 40 | 200 | 145 | 110 | 85 | 16 | 4*φ18 | |||

| 50 | 230 | 160 | 125 | 100 | 16 | 4*φ18 | |||

| 65 | 290 | 180 | 145 | 120 | 18 | 4*φ18 | |||

| 80 | 310 | 195 | 160 | 135 | 20 | 8*φ18 | |||

| 100 | 350 | 215 | 180 | 155 | 20 | 8*φ18 | |||

| 125 | 400 | 245 | 210 | 185 | 22 | 8*φ18 | |||

| 150 | 480 | 280 | 240 | 210 | 24 | 8*φ23 | |||

| 200 | 600 | 335 | 295 | 265 | 26 | 12*φ23 | |||

| 250 | 650 | 405 | 355 | 320 | 30 | 12*φ25 | |||

| 300 | 750 | 460 | 410 | 375 | 34 | 12*φ25 | |||

| 400 | 950 | 580 | 525 | 485 | 36 | 16*φ30 | |||

PRODUCT ADVANTAGES:

1. Loaʻa iā mākou ka ʻenehana hoʻolei ʻana i ke one a i ʻole Precision, no laila hiki iā mākou ke like me kāu hoʻolālā kiʻi a me ka hana.

2. Loaʻa nā logo o nā mea kūʻai aku i hoʻolei ʻia ma ke kino valve.

3. ʻO kā mākou hoʻolei ʻana a pau me ke kaʻina hana tempering ma mua o ka Hana ʻana.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding

6. Every valve must be tested before delivery from the factory, only qualified onescanbe shipped.

7. ʻO ka valve ʻano maʻamau mākou e hoʻohana ai i nā hihia lāʻau e hoʻopili ai, hiki iā mākou ke like me

nā noi a ka mea kūʻai aku.

COMPANY ADVANTAGES:

-

1. ʻO mākou ka mea hana mai ka makahiki 1992.

1. ʻO mākou ka mea hana mai ka makahiki 1992. -

2.CE, API, ISO aponoia.

2.CE, API, ISO aponoia. -

3. Hoʻouna wikiwiki.

3. Hoʻouna wikiwiki. -

4.Low kumu kūʻai me ke kūlana kiʻekiʻe.

4.Low kumu kūʻai me ke kūlana kiʻekiʻe. -

5. ʻOihana hana pūʻulu!

5. ʻOihana hana pūʻulu!