NA PALAPALA HUA:

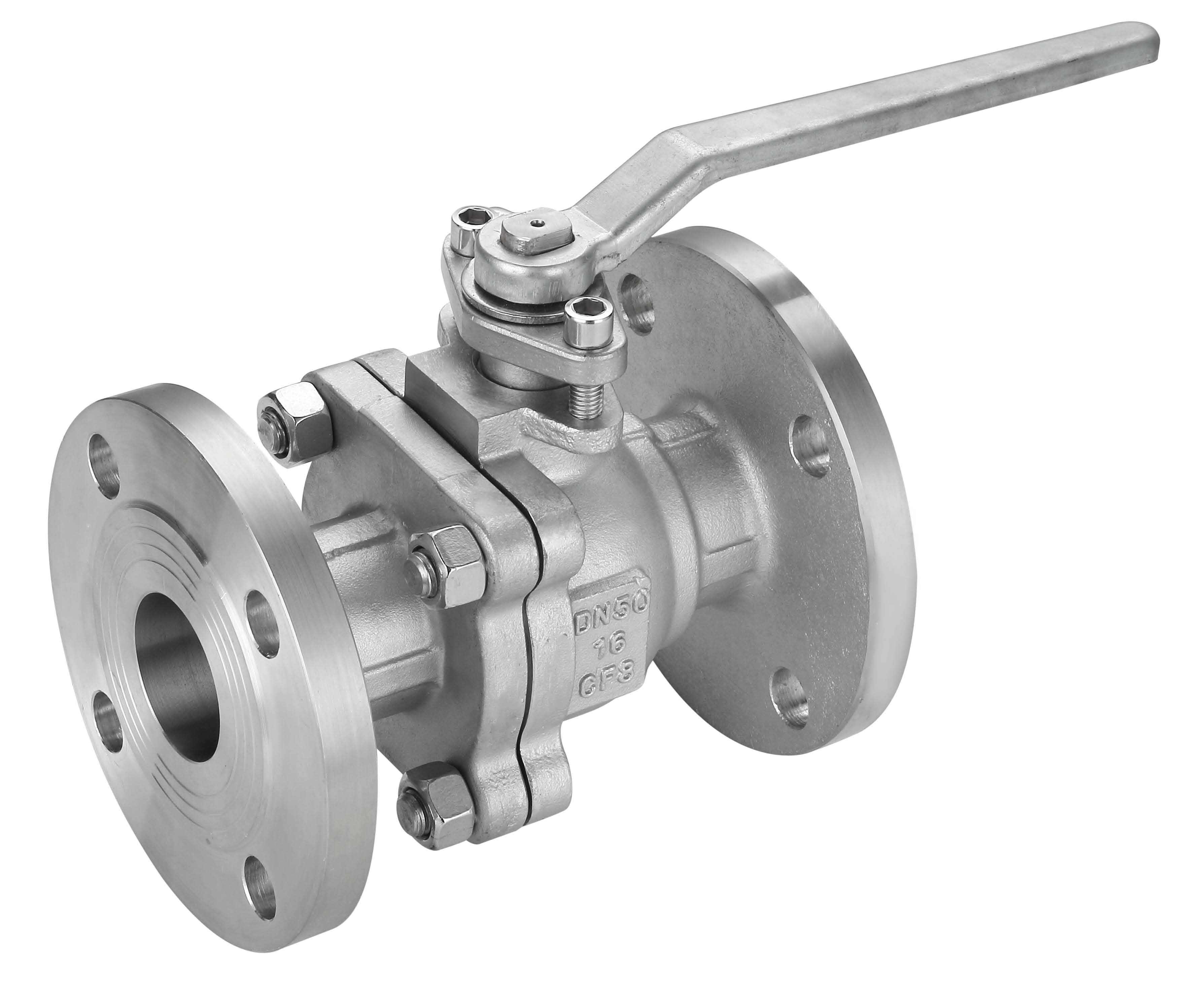

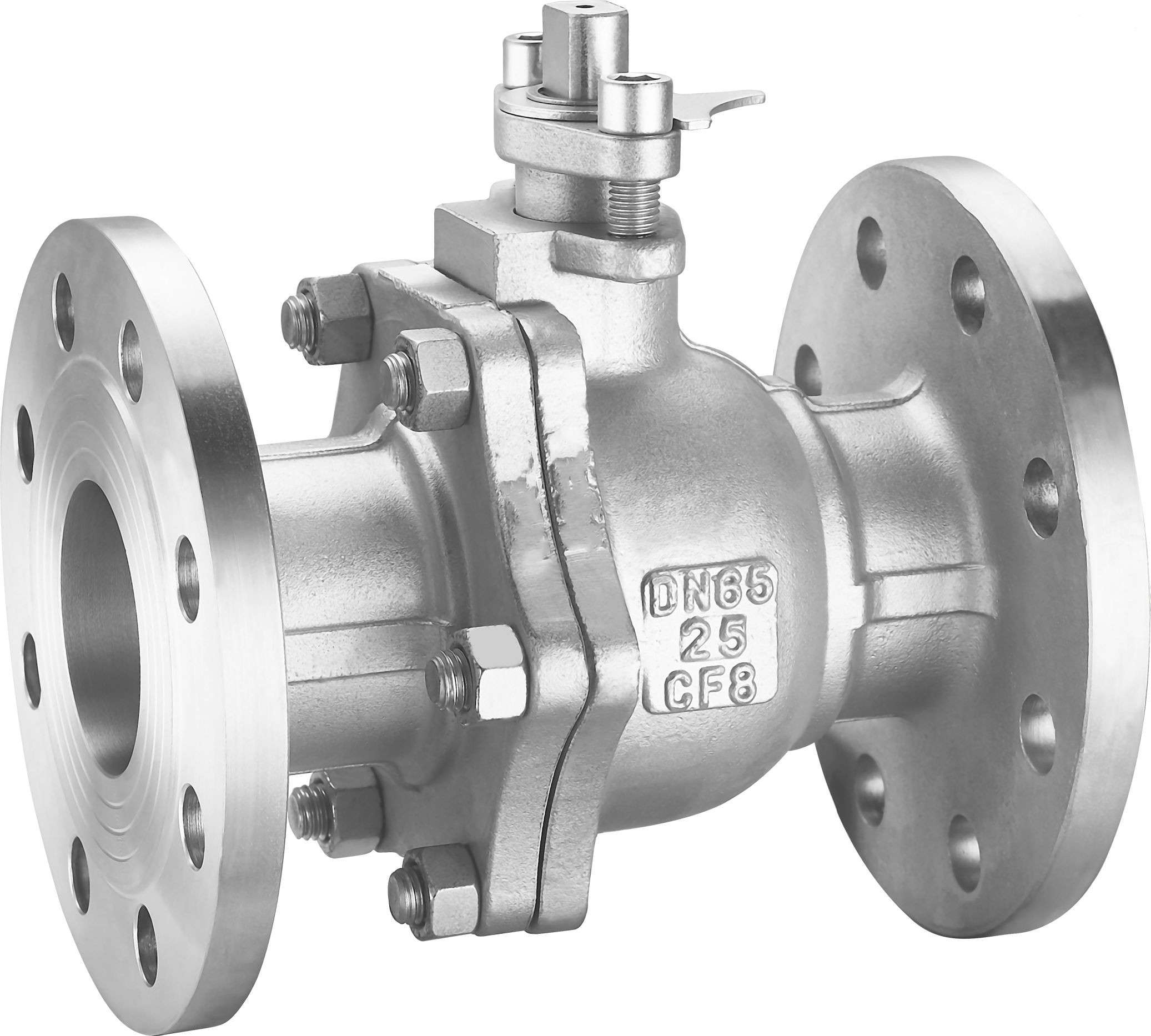

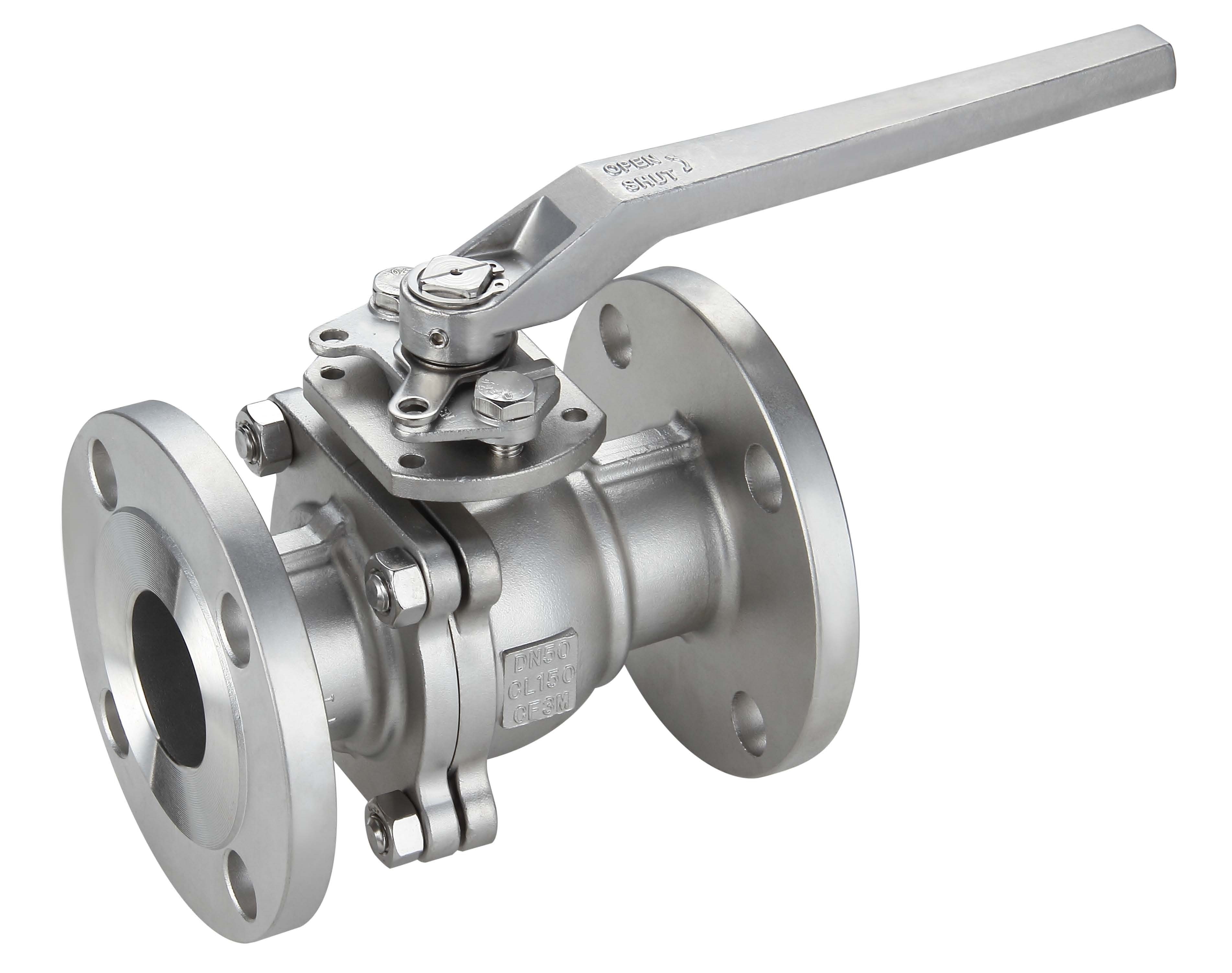

ANSI Floating Ball Valve Material o nā ʻāpana nui

|

ANSI Floating Ball Valve Material o nā ʻāpana nui |

|

|

Inoa Mahele |

mea waiwai |

|

Kino / pāpale |

ASTM A216 WCB, CF8, CF8M |

|

poepoe |

ASTM A105, F304, F316 |

|

Puu puuwai |

ASTM A182 F6a, F304, F316 |

|

Hoʻopaʻa |

PTFE |

ʻO ANSI Floating Ball Valve Q41F nā kikoʻī hana

|

ʻO ANSI Floating Ball Valve Q41F nā kikoʻī hana |

|||||

|

kumu hoʻohālike |

Pumi inoa |

ʻO ke kaomi hoʻāʻo (mpa) wai |

wela kūpono |

ʻAno kūpono |

|

|

ikaika |

sila |

||||

|

Q41F-150LB |

150 |

3.00 |

2.20 |

≤150 ℃ |

Wai, mahu, aila, etc. |

|

Q41F-300LB |

300 |

7.50 |

5.50 |

||

|

Q41F-600LB |

600 |

15.00 |

11.00 |

||

ʻO ANSI nā ʻāpana pōlele lana Q41F a me nā ana pili

|

ʻO ANSI nā ʻāpana pōlele lana Q41F a me nā ana pili |

|||||||

|

kumu hoʻohālike |

Anawaena inoa inoa |

Nui (mm) |

|||||

|

L |

D |

D1 |

D2 |

bf |

z-φd |

||

|

Q41F-150LB |

1/2 " |

108 |

90 |

60.5 |

35 |

11-2 |

4 * φ16 |

|

3/4 " |

117 |

100 |

70 |

43 |

13.5-2 |

4 * φ16 |

|

|

1" |

127 |

110 |

79.5 |

51 |

15-2 |

4 * φ16 |

|

|

1 1/4 " |

140 |

115 |

89 |

63.5 |

16.5-2 |

4 * φ16 |

|

|

1 1/2 " |

165 |

125 |

98.5 |

73 |

18-2 |

4 * φ16 |

|

|

2" |

178 |

150 |

121 |

92 |

19.5-2 |

4 * φ19 |

|

|

2 1/2 " |

190 |

180 |

140 |

105 |

23-2 |

4 * φ19 |

|

|

3 " |

203 |

190 |

152.5 |

127 |

24.5-2 |

4 * φ19 |

|

|

4 " |

229 |

230 |

190.5 |

157 |

24.5-2 |

8 * φ19 |

|

|

6 " |

394 |

280 |

241.5 |

216 |

26-2 |

8 * φ22 |

|

|

8" |

457 |

345 |

298.5 |

270 |

29-2 |

8 * φ22 |

|

|

Q41F-300LB |

1/2 " |

140 |

95 |

66.5 |

35 |

15-2 |

4 * φ16 |

|

3/4 " |

152 |

115 |

82.5 |

43 |

16.5-2 |

4 * φ19 |

|

|

1" |

165 |

125 |

89 |

51 |

18-2 |

4 * φ19 |

|

|

1 1/4 " |

178 |

135 |

98.5 |

63.5 |

19.5-2 |

4 * φ19 |

|

|

1 1/2 " |

190 |

155 |

114.5 |

73 |

21-2 |

4 * φ22 |

|

|

2" |

216 |

165 |

127 |

92 |

23-2 |

8 * φ19 |

|

|

2 1/2 " |

241 |

190 |

149 |

105 |

26-2 |

8 * φ22 |

|

|

3 " |

282 |

210 |

168.5 |

127 |

29-2 |

8 * φ22 |

|

|

4 " |

305 |

255 |

200 |

157 |

32-2 |

8 * φ22 |

|

|

6 " |

403 |

320 |

270 |

216 |

37-2 |

12 * φ22 |

|

|

8" |

502 |

380 |

330 |

270 |

42-2 |

12 * φ25 |

|

Nā noi:

He kūpono kēia kiwi no nā ʻano paipu a pau i hāmama a paʻa loa, ʻaʻole no ka throttling.

Nā Pono o ka Hui:

-

1. ʻO mākou ka mea hana mai ka makahiki 1992.

1. ʻO mākou ka mea hana mai ka makahiki 1992. -

2.CE, API, ISO aponoia.

2.CE, API, ISO aponoia. -

3. Hoʻouna wikiwiki.

3. Hoʻouna wikiwiki. -

4.Low kumu kūʻai me ke kūlana kiʻekiʻe.

4.Low kumu kūʻai me ke kūlana kiʻekiʻe. -

5. ʻOihana hana pūʻulu!

5. ʻOihana hana pūʻulu!

Nā Pono Huahana:

1. Loaʻa iā mākou ka ʻenehana hoʻolei ʻana i ka Sand a i ʻole Precision, no laila hiki iā mākou ke like me kāu hoʻolālā kiʻi kiʻi a me ka hana ʻana.

2. Loaʻa nā logo o nā mea kūʻai aku i hoʻolei ʻia ma ke kino valve.

3. ʻO kā mākou hoʻolei ʻana a pau me ke kaʻina hana tempering ma mua o ka Hana ʻana.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding

6. Every valve must be tested before delivery from the factory, only qualified onescanbe shipped.

7. ʻO ka valve ʻano maʻamau mākou e hoʻohana ai i nā hihia lāʻau e hoʻopili ai, hiki iā mākou ke like me

nā noi a ka mea kūʻai aku.