86-312-8695888

86-312-8695888

86-13722963501

86-13722963501

info@hbysindustry.com

info@hbysindustry.com

More Language

פבר . 13, 2025 20:10

Back to list

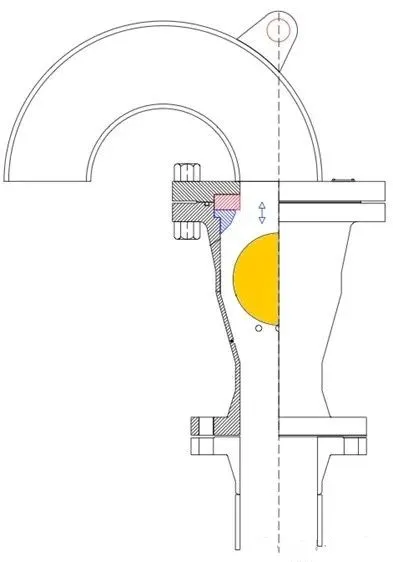

100X Remote Ball Cock 100x Manufacturer China

The rapidly advancing world of automation consistently seeks innovation to enhance efficiency, reliability, and precision in controlling fluid flow. Among the myriad of advancements in fluid control products, the electric actuated needle valve stands out as a sophisticated solution with a plethora of applications across industries. Its growing demand can be attributed to its ability to deliver accuracy, seamless control, and robustness in challenging environments.

Manufacturers of electric actuated needle valves are continually innovating, bringing forth models with enhanced connectivity and smart capabilities. The integration of IoT technology allows these valves to provide real-time data analytics, facilitating predictive maintenance and optimization of fluid dynamics within a plant. This evolution not only enhances operational efficiencies but also extends the lifecycle of the systems, promoting sustainability. Considering authoritativeness, the development and application of electric actuated needle valves are supported by extensive research and collaboration with academic institutions and industrial leaders. The expertise required in their design and implementation ensures these products are developed following stringent quality standards and industry regulations. Trust in these components is built on their proven performance in some of the world’s most demanding industrial settings. Electric actuated needle valves are more than just components of a fluid control system; they embody the fusion of mechanical engineering and digital technology for the enhancement of industrial processes. As industries continue to evolve, the integration of automation and precision control, as exemplified by these needle valves, will play a pivotal role in driving innovation and sustainability in fluid management solutions. In summary, the electric actuated needle valve is not merely a product; it is an essential component that embodies experience, expertise, authoritativeness, and trustworthiness. Its deployment can lead to enhanced efficiency, safety, and operational excellence across diverse industrial applications. Through continuous innovation and rigorously adhering to quality standards, it represents a cornerstone of modern automated control systems.

Manufacturers of electric actuated needle valves are continually innovating, bringing forth models with enhanced connectivity and smart capabilities. The integration of IoT technology allows these valves to provide real-time data analytics, facilitating predictive maintenance and optimization of fluid dynamics within a plant. This evolution not only enhances operational efficiencies but also extends the lifecycle of the systems, promoting sustainability. Considering authoritativeness, the development and application of electric actuated needle valves are supported by extensive research and collaboration with academic institutions and industrial leaders. The expertise required in their design and implementation ensures these products are developed following stringent quality standards and industry regulations. Trust in these components is built on their proven performance in some of the world’s most demanding industrial settings. Electric actuated needle valves are more than just components of a fluid control system; they embody the fusion of mechanical engineering and digital technology for the enhancement of industrial processes. As industries continue to evolve, the integration of automation and precision control, as exemplified by these needle valves, will play a pivotal role in driving innovation and sustainability in fluid management solutions. In summary, the electric actuated needle valve is not merely a product; it is an essential component that embodies experience, expertise, authoritativeness, and trustworthiness. Its deployment can lead to enhanced efficiency, safety, and operational excellence across diverse industrial applications. Through continuous innovation and rigorously adhering to quality standards, it represents a cornerstone of modern automated control systems.

Latest news

-

Top-Quality Pipe and Pipe Fittings for Reliable Fluid SystemsNewsAug.28,2025

-

Reliable Slip On Flange Manufacturer for Industrial ExcellenceNewsAug.28,2025

-

Premium Rubber Expansion Joints for Piping SystemsNewsAug.28,2025

-

Premium Electric Actuators for Smart Automation SolutionsNewsAug.28,2025

-

Innovative Flange Solutions for Modern Plumbing NeedsNewsAug.28,2025

-

High-Performance Exhaust Valves for Efficient Fluid SystemsNewsAug.28,2025

-

Buy WCB Gate Valve: Robust & Reliable Industrial SolutionNewsAug.28,2025