פבר . 11, 2025 23:25

Back to list

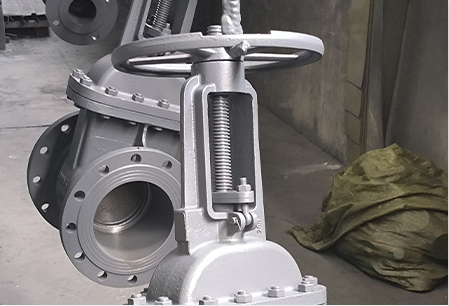

spring loaded globe valve

A spring-loaded globe valve is an integral component in various industrial piping systems, renowned for its precision and reliability. These specialized valves excel in scenarios demanding tight shut-off capabilities and controlled flow rates, thereby enhancing both system efficiency and safety. By harnessing the energy of a spring element, they offer exceptional performance in high-pressure and high-temperature environments, making them an essential asset in industries ranging from oil and gas to pharmaceuticals.

A notable development within the spring-loaded globe valve category is the integration of smart technologies. As part of the growing trend towards Industry 4.0, these valves are being equipped with sensors and connectivity modules that provide real-time data analysis. Such innovations allow for enhanced monitoring of valve health, performance trends, and system diagnostics, paving the way for predictive maintenance strategies and minimizing unplanned downtime. The installation of a spring-loaded globe valve requires a meticulous approach to ensure optimal functionality. It is essential to follow the manufacturer's guidelines concerning the orientation of the valve body and respect the flow direction markings. Proper torquing of the bolts and gaskets during installation can prevent leaks and maintain structural integrity, an area where specialized training can be beneficial for the installation crew. Working with reputable manufacturers and suppliers who adhere to industry standards, such as API, ANSI, and ISO certifications, is paramount. Their expertise not only guarantees a high-quality product but also provides access to comprehensive technical support and warranty services, thereby safeguarding your investment. In summary, spring-loaded globe valves represent a pinnacle of innovation in the valve industry. They combine precision engineering with advanced technologies to deliver solutions that meet the rigorous demands of modern industrial applications. By incorporating these valves, businesses can achieve heightened system reliability, improved operational efficiency, and enhanced safety outcomes. As the landscape of industrial technology continues to evolve, adopting high-performance components such as spring-loaded globe valves is a strategic decision that underscores a commitment to excellence and sustainability.

A notable development within the spring-loaded globe valve category is the integration of smart technologies. As part of the growing trend towards Industry 4.0, these valves are being equipped with sensors and connectivity modules that provide real-time data analysis. Such innovations allow for enhanced monitoring of valve health, performance trends, and system diagnostics, paving the way for predictive maintenance strategies and minimizing unplanned downtime. The installation of a spring-loaded globe valve requires a meticulous approach to ensure optimal functionality. It is essential to follow the manufacturer's guidelines concerning the orientation of the valve body and respect the flow direction markings. Proper torquing of the bolts and gaskets during installation can prevent leaks and maintain structural integrity, an area where specialized training can be beneficial for the installation crew. Working with reputable manufacturers and suppliers who adhere to industry standards, such as API, ANSI, and ISO certifications, is paramount. Their expertise not only guarantees a high-quality product but also provides access to comprehensive technical support and warranty services, thereby safeguarding your investment. In summary, spring-loaded globe valves represent a pinnacle of innovation in the valve industry. They combine precision engineering with advanced technologies to deliver solutions that meet the rigorous demands of modern industrial applications. By incorporating these valves, businesses can achieve heightened system reliability, improved operational efficiency, and enhanced safety outcomes. As the landscape of industrial technology continues to evolve, adopting high-performance components such as spring-loaded globe valves is a strategic decision that underscores a commitment to excellence and sustainability.

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025