PRODUCT PARAMETERS:

| Nominal txoj kab uas hla (mm) |

L | D1 | D | ||||||

| NP10/16 | PN25 / 40 | PN10 | PIB 16 | PN25 PN40 |

PN40 | ||||

| 50 | 15 | 19 | 25 | 104 | 104 | 109 | 109 | ||

| 65 | 15 | 19 | 38 | 125 | 125 | 129 | 129 | ||

| 80 | 16 | 19 | 46 | 140 | 140 | 144 | 144 | ||

| 100 | 16 | 19 | 71.5 | 160 | 160 | 170 | 170 | ||

| 125 | 17 | 19 | 95 | 185 | 185 | 196 | 196 | ||

| 150 | 19 | 29 | 114 | 220 | 220 | 226 | 226 | ||

| 200 | 26 | 29 | 140 | 270 | 270 | 286 | 293 | ||

| 250 | 29 | 38 | 188 | 330 | 331 | 343 | 355 | ||

| 300 | 38 | 51 | 216 | 380 | 386 | 403 | 420 | ||

| 350 | 38 | 45 | 263 | 440 | 446 | 460 | 477 | ||

| 400 | 48 | 55 | 305 | 491 | 495 | 517 | 549 | ||

| 450 | 48 | 60 | 356 | 541 | 558 | 567 | 574 | ||

| 500 | 58 | 70 | 406 | 596 | 620 | 622 | 626 | ||

| 600 | 68 | 78 | 482 | 698 | 732 | 734 | 745 | ||

| 700 | 70 | 80 | 562 | 813 | 804 | 831 | - | ||

| 800 | 75 | 95 | 664 | 918 | 912 | 942 | - | ||

| 900 | 75 | 95 | 738 | 1018 | 1012 | 1040 | - | ||

| 1000 | 90 | 100 | 846 | 1124 | 1126 | 1155 | - | ||

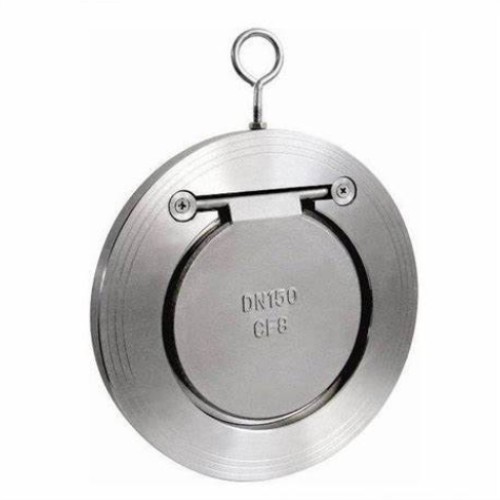

| Lub Npe | khoom | ||

| Lub cev / lub kaus mom | WCB / stainless steel | ||

| Disc | WCB / stainless steel | ||

| Lub nplhaib sealing | NBR / EPDM / PTFE / steel |

| qauv | Nominal siab (mpa) |

xeem siab | qhov kub thiab txias | Siv tau nruab nrab | |||||

| Lub zog (dej) | Sealed (dej) | ||||||||

| H74H / X-10 | 1.0 | Working pressure * 1.5 | Working pressure * 1.1 | ≤400 ℃ | Water and seal material selection | ||||

| H74H / X-16 | 1.6 | ||||||||

| H74H / X-25 | 2.5 | ||||||||

| H74H / X-40 | 4.0 | ||||||||

Tswv yim:

1.Compact qauv, tsim nyog tsim, zoo valve rigidity, du passage.

2.Kev siv cov graphite packing saj zawg zog, txhim khu kev qha sealing, lub teeb thiab saj zawg zog ua hauj lwm

Daim ntawv thov:

Industrial applications: Petroleum, Chemical, Paper Making, Fertilizer, Coal Mining,water treatment and etc.

PRODUCT ADVANTAGES:

1.Peb muaj Sand lossis Precision casting tshuab, Yog li peb tuaj yeem ua koj tus qauv tsim thiab tsim khoom.

2.Cov neeg siv khoom lub logo muaj nyob rau ntawm lub valve lub cev.

3. Tag nrho peb cov casting nrog tempering txheej txheem ua ntej ua.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding.

6. Every valve must be tested before delivery from the factory, only qualified ones can be shipped.

7.Qhov zoo valve peb feem ntau siv Hnab rau pob, Peb kuj tuaj yeem ua raws li cov neeg siv khoom thov.

COMPANY ADVANTAGES:

-

1.Peb yog cov chaw tsim khoom txij li xyoo 1992.

1.Peb yog cov chaw tsim khoom txij li xyoo 1992. -

2.CE, API, ISO pom zoo.

2.CE, API, ISO pom zoo. -

3. Kev xa khoom sai.

3. Kev xa khoom sai. -

4. Tus nqi qis nrog cov khoom zoo.

4. Tus nqi qis nrog cov khoom zoo. -

5. Pab neeg ua haujlwm tshaj lij!

5. Pab neeg ua haujlwm tshaj lij!