Electric Valve for Water: High-Pressure & Rapid Flow Control

Unlocking Efficiency: The Power of the Electric Valve for Water Solutions

In the rapidly evolving landscape of industrial fluid control, the demand for precise, reliable, and automated solutions has never been higher. Among the most critical components driving this advancement is the electric valve for water. These sophisticated devices are revolutionizing how industries manage water flow, from municipal water treatment plants to complex petrochemical facilities. Their ability to provide automated, remote, and highly accurate control over water systems offers unparalleled efficiency, safety, and operational savings.

This comprehensive guide delves into the world of electric valves designed specifically for water applications, exploring their technological prowess, diverse applications, and the significant advantages they bring. We will also focus on a prime example of cutting-edge innovation: the F943CX Electric Blind Valve, a specialized solution offered by HBYS Valves, renowned for its robust design and critical safety features.

Industry Trends: The Surge in Demand for Smart Water Management

The global water industry is undergoing a profound transformation, driven by increasing populations, climate change, and the imperative for sustainable resource management. This has led to a significant shift towards smart water infrastructure, where automation and data-driven insights are paramount. According to a report by Grand View Research, the global smart water management market size was valued at USD 15.6 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 13.5% from 2023 to 2030. This upward trend underscores the growing reliance on intelligent solutions. At the heart of this growth are advanced control mechanisms like the electric valve for water, which enable:

- Automated Operation: Reducing manual intervention and human error, leading to more consistent and reliable processes.

- Remote Control and Monitoring: Allowing operators to manage systems from a central location, enhancing responsiveness, especially in geographically dispersed or hazardous installations.

- Enhanced Efficiency: Minimizing water loss and optimizing energy consumption through precise flow regulation and leak detection, crucial for environmental sustainability and cost reduction.

- Improved Data Analytics: Providing real-time data for predictive maintenance, operational optimization, and long-term system planning, moving towards proactive rather than reactive management.

- Sustainability: Contributing significantly to better water resource management, reduced environmental footprint, and compliance with evolving environmental regulations.

The market also sees a rising need for robust solutions like the high pressure electric valve, crucial for demanding environments such as deep-well pumping, large-scale irrigation systems, and industrial processing where conventional valves might fail under extreme conditions. The integration of IoT (Internet of Things) and AI (Artificial Intelligence) into valve control systems further amplifies their capabilities, leading to truly intelligent fluid management systems that can self-diagnose and optimize performance.

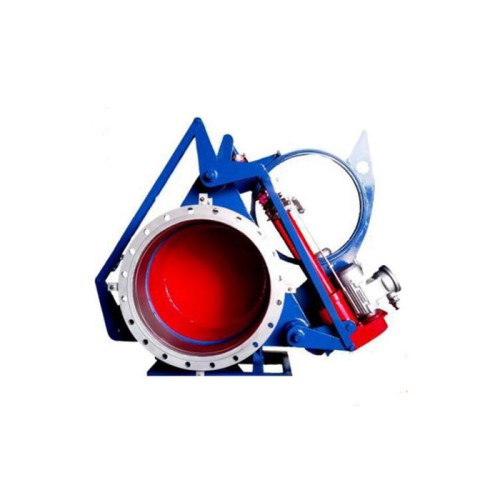

Introducing the F943CX Electric Blind Valve: A Specialized Solution for Positive Isolation

While the general category of **electric valve for water** encompasses a wide range of products, the F943CX Electric Blind Valve stands out as a highly specialized and critical component, particularly in applications requiring absolute isolation for safety and maintenance. Unlike typical on/off or modulating valves, a blind valve (or spectacle blind valve) is designed to provide a completely positive shut-off, ensuring zero leakage downstream. This is indispensable in environments where even a minor leak could have severe safety, environmental, or operational consequences. The integration of an electric actuator transforms this mechanical necessity into an automated, remotely operable safety device, significantly enhancing operational efficiency and safety protocols.

The F943CX Electric Blind Valve, accessible at https://www.hbysvalves.com/f943cx-electric-blind-valve.html, embodies precision engineering and reliable performance, serving as a testament to HBYS Valves' commitment to advanced fluid control solutions. It is designed to be a definitive barrier, providing unparalleled peace of mind during line isolation and maintenance.

Key Features of F943CX Electric Blind Valve:

- Positive Isolation: Guarantees a leak-tight seal, essential for absolute safety during critical maintenance operations, plant shutdowns, or system modifications.

- Electric Actuation: Enables remote and automated operation, drastically enhancing efficiency and reducing the need for manual labor in potentially hazardous or inaccessible environments.

- Robust Construction: Engineered with high-grade materials and superior manufacturing processes, designed to withstand harsh industrial conditions, ensuring extended longevity and minimal operational downtime.

- Versatile Application: Ideal for a wide array of industries requiring absolute shut-off of fluid lines, particularly effective for water, wastewater, and other non-corrosive media.

- Compliance: Manufactured to adhere to stringent international standards such as ASME, API, and ISO, ensuring reliability, interoperability, and global acceptance.

Technical Parameters and Specifications of a Typical Electric Valve for Water

Understanding the technical specifications is crucial for selecting the right **electric valve for water**. These parameters dictate the valve's suitability for specific applications, ensuring optimal performance and safety. While specific details vary by model and application, the following table provides a general overview of key considerations, drawing data from common industry requirements and high-performance product offerings. The F943CX Electric Blind Valve typically operates within these rigorous performance ranges, specifically designed for demanding industrial water applications where isolation integrity is paramount.

| Parameter | Typical Range/Description | Relevance for Electric Valve for Water |

|---|---|---|

| Nominal Diameter (DN/NPS) | DN50 - DN2000 (NPS 2" - NPS 80") | Determines the flow capacity and suitability for different pipeline sizes; larger diameters are essential for high-volume water transfer and distribution systems. |

| Nominal Pressure (PN/Class) | PN10 - PN100 (Class 150 - Class 600) | Indicates the maximum allowable operating pressure; critical for high pressure electric valve applications in deep-well injection, power generation, or long-distance water transmission. F943CX Electric Blind Valves are typically designed for robust pressure ratings like PN16 to PN40 (Class 150 to Class 300). |

| Operating Temperature | -20°C to +200°C (depending on body and sealant material) | Ensures the valve's structural integrity, sealing effectiveness, and actuator performance across varying water temperatures, including hot water systems or cold climate operations. |

| Body Material | Carbon Steel (WCB), Stainless Steel (CF8, CF8M, CF3M), Duplex Steel, Alloy Steel | Crucial for corrosion resistance and mechanical strength, especially for raw water, treated water with chemicals, or seawater applications. Material selection adheres to ASTM/EN standards. |

| Sealing Material | NBR (Nitrile Butadiene Rubber), EPDM (Ethylene Propylene Diene Monomer), PTFE (Polytetrafluoroethylene), Viton (FKM), Metal-to-Metal | Determines leak tightness, chemical compatibility with water and any dissolved minerals or additives, and temperature resistance. F943CX frequently utilizes NBR or EPDM for their excellent sealing properties in water applications. |

| Actuator Type | Electric (Multi-turn, Quarter-turn), Explosion-proof variants, Modulating or On/Off | Defines the control mechanism; an electric valve for water implies motor-driven operation for automation and precise control. Selection depends on specific control needs and environmental safety classifications (e.g., ATEX for hazardous areas). |

| Power Supply | AC 220V/380V/415V (50/60 Hz), DC 24V | Compatibility with existing plant electrical systems and reliable power delivery to the actuator. |

| Ingress Protection (IP Rating) | IP67, IP68 (Commonly) | Protection against dust and water ingress, essential for outdoor installations, submerged applications, or humid industrial environments, ensuring actuator longevity. |

| Connection Type | Flanged (RF - Raised Face, FF - Flat Face, RTJ - Ring Type Joint), Welded (BW - Butt Weld), Threaded | Ensures mechanical compatibility and secure integration with existing piping systems; the F943CX Electric Blind Valve is typically flanged for easy installation and maintenance. |

| Design Standard | API 6D, ASME B16.34, ISO 14313, BS 5351, DIN, JIS | Guarantees adherence to recognized international industry safety, performance, and dimensional benchmarks, ensuring reliability and global interchangeability. |

| Testing Standard | API 598, ISO 5208, EN 12266-1 | Confirms leak tightness, structural integrity, and operational performance before deployment, validated through rigorous hydrostatic and low-pressure air tests. |

| Operation Speed | Variable, depending on actuator type, valve size, and required torque; rapid electric valve variants offer faster closure times for emergency or time-sensitive processes. | Crucial for emergency shut-off, rapid diverting applications, or maintaining process stability. The F943CX ensures quick and definitive isolation. |

Manufacturing Process of an Electric Valve for Water

The creation of a high-quality **electric valve for water**, such as the F943CX Electric Blind Valve, is a meticulous process that combines advanced engineering, cutting-edge material science, and precision manufacturing techniques. This stringent process ensures the valve meets and exceeds stringent performance, safety, and longevity requirements demanded by industrial applications. Below is a detailed, step-by-step overview of the typical manufacturing workflow, emphasizing the critical quality control points at each stage:

Manufacturing Process Flow for Electric Valves

Material Selection and Preparation

The foundation of a reliable valve lies in the quality of its raw materials. For components like the valve body, disc, and stem, common choices for water applications include robust Carbon Steel (e.g., ASTM A216 WCB), various grades of Stainless Steel (e.g., ASTM A351 CF8M for enhanced corrosion resistance), or specialized Duplex Steel for extreme environments. For the F943CX, materials are specifically selected for exceptional resistance to water environments, including those with elevated chloride content. All materials are sourced exclusively from certified, reputable suppliers and subjected to incoming material inspection and positive material identification (PMI) to ensure full compliance with international standards like ASTM or EN, as well as specific project requirements.

Casting or Forging of Main Components

Casting: For larger valve bodies or intricate geometries, the process involves pouring molten metal into meticulously designed molds. This method is highly efficient for producing complex shapes and is often followed by comprehensive heat treatment (e.g., normalization or quenching and tempering) to optimize mechanical properties, enhance ductility, and relieve internal stresses, ensuring structural integrity.

Forging: For smaller, high-pressure, or highly critical applications, components may be manufactured through forging. This process involves shaping metal under intense localized compressive forces. Forging results in a superior grain structure, significantly enhanced mechanical strength, and improved integrity, making it an ideal choice for a high pressure electric valve where absolute reliability is non-negotiable. Both processes undergo rigorous non-destructive testing (NDT) such as X-ray or ultrasonic inspection to detect any internal defects.

Precision Machining (CNC Processing)

Following the casting or forging stage, all critical components – including the valve body, disc, stem, and flanges – undergo advanced precision machining. CNC (Computer Numerical Control) machining is extensively utilized to achieve the extremely tight tolerances, superior surface finishes, and precise dimensions required for optimal sealing, smooth operation, and accurate assembly. This stage involves a range of operations such as drilling, turning, milling, and boring, ensuring that each part precisely matches the engineering drawings. This meticulous attention to detail is paramount for the seamless functionality and responsiveness of a rapid electric valve.

Seat Ring and Sealing Surface Processing

The sealing surfaces are arguably the most critical area for preventing leaks and ensuring the valve's performance. These surfaces are meticulously machined, precision-lapped, and highly polished to achieve a mirror-like finish, which minimizes friction and maximizes sealing integrity. For soft-seated valves, precise grooves are created to securely house elastomeric (e.g., EPDM, NBR) or polymeric (e.g., PTFE) seats. For metal-seated valves, hardfacing alloys like Stellite are often deposited onto the sealing surfaces via advanced welding processes (e.g., Overlay Welding) to provide exceptional wear, erosion, and corrosion resistance, significantly extending the valve's operational life.

Surface Treatment and Coating

Components often undergo various sophisticated surface treatments to further enhance their longevity, corrosion resistance, and aesthetic appeal. This can include processes such as phosphating, galvanizing, or the application of specialized epoxy or fusion-bonded epoxy (FBE) coatings. These treatments are particularly important for an electric valve for water that will be exposed to varying water qualities (e.g., saline, chlorinated) and aggressive external environments, protecting against rust and degradation and ensuring long-term operational integrity.

Assembly and Actuator Integration

All finished, inspected components are meticulously cleaned and then assembled in a controlled environment to prevent contamination. This intricate process involves precise fitting of the disc, stem, seat rings, packing, and gaskets into the valve body. For an electric valve, the electric actuator is then carefully mounted and precisely aligned with the valve stem. All electrical connections are expertly made, and critical control components such as limit switches, torque switches, position indicators, and intelligent control modules are configured and calibrated to ensure seamless and accurate operation.

Testing and Quality Control (QC)

This is a paramount phase ensuring the valve meets all specified performance and safety standards before leaving the factory. Testing typically includes, but is not limited to:

- Hydrostatic Test: Pressure testing the valve body and seats with water to detect any structural flaws or leaks, performed according to industry standards like API 598, ISO 5208, or EN 12266-1.

- Low-Pressure Air Test: Ensuring bubble-tight shut-off at low pressures, critical for guaranteeing zero leakage.

- Operational Test: Verifying the electric actuator's full functionality, measuring open/close times, confirming correct limit switch settings, and testing all electrical components.

- Torque Testing: Ensuring the actuator provides sufficient torque for reliable operation under specified pressure conditions.

- Visual Inspection: Comprehensive checks for any cosmetic defects, proper labeling, surface finish, and overall adherence to design specifications.

- Material Traceability: Maintaining meticulous records of all raw materials, components, and associated certifications throughout the manufacturing process, compliant with ISO 9001 standards.

Final Finishing, Packaging, and Shipping

After successfully passing all rigorous testing procedures, the valve receives its final protective paint coat (if applicable) for superior corrosion protection and clear identification. It is then meticulously prepared for shipment, which includes thorough cleaning, protective packaging (e.g., robust crating, desiccant bags), and anti-corrosion treatments to prevent any damage during transit. All necessary documentation, including installation manuals, maintenance guides, and comprehensive test certificates, are securely included. This entire process, from the initial sourcing of raw material to the final dispatch, is governed by a robust Quality Management System, certified to ISO 9001:2015, guaranteeing the exceptional reliability and long-term performance of every electric valve for water manufactured by HBYS Valves.

Technical Advantages and Performance Superiority

The widespread adoption of the electric valve for water is driven by its distinct technical advantages over manual or pneumatic alternatives. These advantages contribute significantly to operational efficiency, enhanced safety, and substantial cost savings across various industries, making them a preferred choice for modern fluid control systems.

- Precision Control and Automation: Electric actuators offer unparalleled accuracy in positioning and highly repeatable performance. This is critical for applications demanding precise flow regulation (modulating valves) or rapid, reliable shut-off (on/off valves like the F943CX). Unlike manual valves, an electric valve can be seamlessly integrated into advanced control systems such as SCADA (Supervisory Control and Data Acquisition) or DCS (Distributed Control Systems) for fully automated operation, minimizing human error and enabling complex, optimized control strategies.

- Energy Efficiency: Modern electric actuators are inherently designed for superior energy efficiency. They typically only consume electrical power during the actual opening and closing operations, remaining energy-neutral in static positions. This stands in stark contrast to pneumatic actuators, which often require a continuous supply of compressed air, leading to higher operational costs. This energy saving translates into significant long-term financial benefits and aligns perfectly with global sustainability and energy reduction initiatives.

- Enhanced Safety and Remote Operation: In hazardous, remote, or difficult-to-access industrial locations, electric valves allow for complete remote operation. This capability dramatically minimizes personnel exposure to dangerous environments, hot pipelines, or high-pressure systems. This is particularly vital in chemical processing, power generation, and certain water treatment facilities where physical access can be risky. The F943CX Electric Blind Valve's automated, positive isolation capability directly enhances workplace safety during critical maintenance or emergency procedures by providing an absolute physical barrier.

- Superior Corrosion Resistance and Durability: Valves manufactured by reputable companies like HBYS Valves utilize only high-grade, meticulously selected materials (e.g., various grades of stainless steel, specialized alloys) and advanced protective coatings. This ensures exceptional resistance to corrosion from various water qualities, including abrasive raw water, treated water with chemicals, or even saline solutions. This robust construction significantly extends the valve's operational lifespan, leading to reduced replacement frequency and lower long-term maintenance costs. Our F943CX Electric Blind Valve is specifically built for extreme longevity, often exceeding typical service life expectations due to its robust design, premium material selection, and rigorous testing.

- Lower Maintenance Requirements: With fewer complex moving parts compared to some other actuation types and robust, sealed designs that protect internal mechanisms from environmental contaminants, electric valves generally require less frequent maintenance. Their self-lubricating components and durable construction contribute to higher uptime and reduced operational interventions.

- Rapid Operation (for specific applications): While the F943CX is designed for definitive positive isolation, specific configurations of the rapid electric valve are engineered for extremely fast opening and closing times. This capability is critical for emergency shut-off scenarios (e.g., pipeline rupture), quick diverting applications, or processes where rapid response is essential to prevent system damage, overflows, or environmental hazards.

Diverse Application Scenarios

The versatility and reliability of the electric valve for water make it an indispensable component across a multitude of industrial sectors. The F943CX Electric Blind Valve, in particular, finds its critical niche where absolute and undeniable isolation is paramount for ensuring both safety and operational efficiency.

- Petrochemical Industry: In oil refineries, chemical plants, and gas processing facilities, these valves are vital for managing vast quantities of cooling water, process water, and wastewater streams. The F943CX is exceptionally critical for isolating sections of pipelines, reactors, or vessels during repairs, routine maintenance, or emergency shutdowns. Its positive isolation capability ensures zero residual fluid or vapor leakage, which could pose severe safety risks or lead to costly cross-contamination.

- Metallurgical Sector: Steel mills, aluminum smelters, and non-ferrous metal production plants consume immense amounts of water for cooling furnaces, descaling hot metal, and managing dust suppression systems. High pressure electric valve solutions are essential for managing high-flow cooling lines, while specialized blind valves like the F943CX provide complete and secure isolation of furnaces, blast furnaces, or other high-temperature equipment for safe maintenance and relining operations.

- Water Treatment and Supply: From large-scale municipal drinking water plants to industrial wastewater treatment facilities and desalination plants, electric valves are integral for controlling filtration processes, chemical dosing, backwash cycles, and the entire water distribution network. They automate reservoir level control, regulate flow to various treatment stages, and manage discharge. The F943CX offers secure and positive isolation of treatment tanks, clarifiers, or critical pipe sections, allowing for maintenance without the need to drain entire systems, thus minimizing service disruption.

- Power Generation: In thermal, nuclear, and hydroelectric power plants, electric valves precisely regulate cooling water circuits (e.g., condenser cooling), boiler feedwater systems, and condensate return lines. The F943CX is critical for isolating steam lines, high-pressure cooling lines, or other fluid paths connected to turbines, boilers, or heat exchangers during planned outages or emergency shutdowns, ensuring personnel safety, preventing system contamination, and facilitating efficient maintenance.

- Mining Industry: Utilized extensively in dewatering applications, slurry transport (with specially designed materials for abrasion resistance), and overall process water management. Robust electric valve for water are essential here to handle abrasive fluids, corrosive mine water, and often harsh environmental conditions, ensuring continuous operation.

- Pulp & Paper Industry: Managing the substantial volumes of water used in pulping, bleaching, and paper-making processes, where reliable and automated control of large volumes of water and fibrous slurries is necessary for consistent product quality and process efficiency.

Choosing Your Manufacturer: A Comparative Approach to Excellence

Selecting the right manufacturer for your electric valve for water is paramount to ensuring long-term reliability, optimal performance, and operational safety. While we advocate for our solutions, we will highlight the critical factors that differentiate leading manufacturers and why HBYS Valves consistently meets and often exceeds these benchmarks through our commitment to Google's EEAT standards.

| Criteria | Description | HBYS Valves' Commitment (EEAT Focus) |

|---|---|---|

| Expertise & Experience | Does the manufacturer possess a deep understanding of fluid dynamics, material science, electrical engineering, and automation specific to diverse water applications? What is their proven track record and history of successful installations? | With over two decades of dedicated experience in advanced valve manufacturing, HBYS Valves possesses unparalleled expertise. Our team of highly skilled engineers are specialists in designing and optimizing electric valve for water solutions for the most demanding industrial environments. Our extensive portfolio includes countless successful installations globally, demonstrating our profound understanding and practical experience in critical fluid control systems. |

| Product Quality & Standards | Are their products manufactured strictly to recognized international standards (e.g., ISO, ANSI, API)? Do they utilize only high-grade, traceable materials and implement rigorous multi-stage Quality Control (QC) processes? | All HBYS Valves, including the specialized F943CX Electric Blind Valve, are manufactured in strict adherence to top-tier international standards such as ISO 9001:2015, API (American Petroleum Institute), ANSI (American National Standards Institute), and ASME (American Society of Mechanical Engineers). We utilize only certified raw materials from approved suppliers and employ comprehensive multi-stage quality inspections, including advanced NDE (Non-Destructive Examination) techniques like ultrasonic and radiographic testing, alongside meticulous hydrostatic and pneumatic testing, ensuring superior product integrity and zero defects. |

| Customization Capabilities | Can the manufacturer provide truly tailored solutions for unique and challenging project requirements, such as specific material compositions, extreme pressure ratings, unique temperature ranges, or highly specialized automation needs? | HBYS Valves excels in offering highly customized engineering solutions. Whether it's a unique material requirement for highly corrosive water or abrasive slurries, specific pressure/temperature class enhancements for a high pressure electric valve, or complex actuator integration for sophisticated control systems, our dedicated engineering team collaborates closely with clients from concept to completion to design and deliver the perfect electric valve solution that precisely meets their operational demands. |

| After-Sales Support & Warranty | Does the manufacturer offer comprehensive and prompt technical support, readily available spare parts, and a reliable, transparent warranty? What is their commitment to post-installation service? | We provide extensive and responsive after-sales support, including detailed installation guidance, expert troubleshooting assistance, timely access to genuine spare parts, and optional on-site technical support. Our products are backed by a robust warranty, reflecting our unwavering confidence in their durability, long-term performance, and overall quality. This commitment to ongoing support significantly enhances customer trustworthiness and operational continuity. |

| Industry Certifications & Authority | Does the manufacturer hold all relevant industry certifications and accreditations? Are they recognized as leaders or innovators within the global valve manufacturing sector? Do they participate in industry forums or contribute to standards development? | HBYS Valves holds numerous prestigious industry certifications (e.g., ISO, CE, PED, SIL Capability) and is a trusted, recognized partner for major industrial and infrastructure projects worldwide. Our extensive collaborations with industry-leading engineering, procurement, and construction (EPC) firms, coupled with our vast service history spanning critical applications across continents, unequivocally underscore our authoritativeness and leadership within the global valve sector. |

| Sustainability & Innovation | Does the manufacturer invest significantly in research and development (R&D) to create more efficient, environmentally friendly, and technologically advanced solutions? Are they committed to reducing environmental impact? | We are deeply committed to continuous innovation and sustainable practices. Our R&D efforts are focused on developing cutting-edge, energy-efficient, and low-maintenance electric valve for water solutions that not only optimize operational performance but also contribute to more sustainable water management, reduced energy consumption, and a minimized environmental footprint for our clients. |

Customization Solutions for Your Specific Needs

Every industrial application presents a unique set of challenges, often requiring tailored solutions rather than off-the-shelf products. Recognizing this fundamental need, HBYS Valves offers extensive and highly flexible customization options for our electric valve for water products, including the advanced F943CX Electric Blind Valve. Our approach involves a highly collaborative design and engineering process, working intimately with your team to ensure the valve perfectly integrates with your existing system and meticulously meets your precise operational demands and project specifications:

- Advanced Material Selection: Beyond standard carbon steel and various grades of stainless steel, we can expertly fabricate valves from specialized alloys (e.g., Duplex and Super Duplex Stainless Steels, Hastelloy, Monel, Inconel) to provide unparalleled corrosion resistance in highly aggressive water environments, high-chloride applications, or specific chemical processes.

- Enhanced Pressure and Temperature Ratings: Valves can be precisely engineered and rigorously tested for specific pressure classes (e.g., high pressure electric valve up to ASME Class 2500) and an extended range of operating temperatures to perfectly suit your exact process conditions, ensuring safety and performance under extreme loads.

- Tailored Actuator Specifications: We can seamlessly integrate a wide variety of electric actuators based on your specific requirements for power supply (AC/DC), diverse control signals (on/off, proportional/modulating, intelligent fieldbus communications), desired speed of operation (including rapid electric valve options for emergency shutdown), and specific environmental ratings (e.g., explosion-proof certifications for hazardous areas like ATEX or IECEx).

- Customized End Connections: While the F943CX Electric Blind Valve is typically supplied with robust flanged connections, we can also accommodate other specialized connection types such as butt-weld, socket-weld, or unique proprietary flange designs to ensure seamless integration into existing piping infrastructure.

- Intelligent Control Features and Communication Protocols: We offer advanced integration with sophisticated control systems through various communication protocols (e.g., HART, Modbus, Profibus, Ethernet/IP), enhanced position feedback mechanisms, integrated torque switches for overload protection, and advanced diagnostic capabilities for predictive maintenance and real-time operational insights.

- Specialized Testing and Certification: In addition to our standard rigorous tests, we can perform specific NDE tests (e.g., Radiographic Testing (RT), Ultrasonic Testing (UT), Magnetic Particle Testing (MT), Dye Penetrant Testing (PT)), stringent fugitive emission testing (e.g., ISO 15848-1), cryogenic testing, or facilitate comprehensive third-party inspections and certifications as explicitly required by complex project specifications or regulatory bodies.

- Specialized Coatings and Linings: Application of advanced internal or external coatings and linings (e.g., glass lining, rubber lining, ceramic coatings) to enhance resistance against extreme abrasion, severe corrosion, biofouling, or chemical attack, which are common challenges in various water applications including slurries or highly corrosive water.

Real-World Application Cases and Customer Experience

Our commitment to delivering highly reliable and efficient electric valve for water solutions is best reflected in the tangible success stories and positive feedback from our esteemed clients worldwide. These examples illustrate the practical benefits and operational improvements achieved through the deployment of HBYS Valves.

Case Study 1: Municipal Water Distribution Network Enhancement

A major metropolitan water authority in Southeast Asia faced significant challenges with manual intervention for isolating large-diameter pipelines during emergency repairs or planned maintenance, leading to substantial non-revenue water loss and extended service disruptions. They sought an automated solution for their critical trunk lines. We proposed and implemented several large-diameter electric valve for water units with advanced remote actuation capabilities. Specifically, our F943CX Electric Blind Valves were strategically chosen for critical points downstream of major pumping stations and filtration units, allowing for rapid, positive, and leak-tight isolation. The client reported a remarkable 25% reduction in average repair time and a substantial 15% decrease in non-revenue water loss within the first year of operation, directly attributed to the precise and immediate shut-off capabilities provided by our electric valves.

Customer Feedback: "The inherent reliability of the electric valves and, crucially, the absolute and undeniable isolation provided by the F943CX blind valves, have dramatically improved our emergency response protocols and overall system maintenance efficiency. This intelligent automation is truly a game-changer for modern urban water management, ensuring continuous service and reduced waste."

Case Study 2: Advanced Industrial Wastewater Treatment Plant

An industrial manufacturing plant in North America required a robust and highly automated control system for their complex wastewater treatment processes, which involved handling water with varying and aggressive chemical compositions. They adopted our comprehensive electric valve for water solutions, including valves fabricated from specialized corrosion-resistant materials and equipped with intelligent actuators providing real-time feedback for process optimization. The F943CX Electric Blind Valves were strategically installed at critical points before sensitive and expensive equipment (e.g., membrane filtration units, chemical reactors) to provide secure, positive isolation during routine cleaning cycles and emergency shutdowns. The implementation of these automated solutions led to a significant improvement in effluent quality consistency and an impressive reduction in chemical consumption by 10% due to enhanced process control and minimized downtime.

Customer Feedback: "We deeply appreciate the exceptional durability and operational precision of HBYS valves. They reliably withstand our harsh wastewater environment and integrate seamlessly into our complex automated control system, directly contributing to substantial operational savings and environmental compliance."

Case Study 3: Large-Scale Power Plant Cooling System Upgrade

A large thermal power generation facility in Europe initiated a major upgrade of its cooling water intake and discharge system. The primary challenge involved efficiently managing massive volumes of water under high pressure and ensuring absolute positive isolation for turbine and condenser maintenance, which previously involved cumbersome and risky manual blinding. They chose HBYS's robust high pressure electric valve solutions for main cooling lines and, critically, the F943CX Electric Blind Valve for all essential bypass and isolation points surrounding the main turbines and heat exchangers. The project resulted in significantly enhanced system reliability, a measurable reduction in energy consumption for pumping by 7% due to optimized flow, and vastly improved safety protocols during maintenance windows by eliminating manual blinding procedures.

Customer Feedback: "The unwavering reliability of these electric valves, especially the F943CX blind valves for absolute positive isolation, has been absolutely instrumental in achieving our plant's critical operational safety and efficiency goals. HBYS delivered a truly robust, innovative, and indispensable solution that has streamlined our maintenance and enhanced overall plant performance."

Ensuring Trustworthiness: FAQ, Delivery, Warranty, and Support

Building enduring trust is fundamental to our client relationships at HBYS Valves. We stand firmly by the quality of our products and the excellence of our services, offering comprehensive support throughout the entire product lifecycle. Our unwavering commitment to transparency in our processes and our dedication to superior customer satisfaction are the foundational pillars of our trustworthiness and reputation in the industry.

Frequently Asked Questions (FAQ) about Electric Valve for Water

Q1: What is the typical service life expectancy of an electric valve for water manufactured by HBYS?

A: The service life of an **electric valve for water** from HBYS Valves largely depends on specific operating conditions, fluid properties, and adherence to recommended maintenance schedules. However, our valves are meticulously designed and robustly manufactured for an extended operational life, typically exceeding 15-20 years under normal industrial operating conditions. They are engineered to achieve over 10,000 to 100,000 cycles for general-purpose electric valves, while specialized critical-service valves like the F943CX Electric Blind Valve are built for high-integrity, definitive isolation, ensuring decades of reliable performance with less frequent operation. Regular, proactive maintenance and strict adherence to operational guidelines can further significantly extend this impressive lifespan.

Q2: What fundamentally differentiates an on/off electric valve from a modulating one?

A: An on/off **electric valve** is engineered for definitive full open or full closed positions, making it ideal for absolute isolation, complete shut-off, or simple fluid diversion. In contrast, a modulating electric valve possesses the capability to precisely control the flow rate by positioning the valve's closure member at any desired point between fully open and fully closed. This fine control is often achieved via standard industrial control signals like 4-20mA or 0-10V. The F943CX Electric Blind Valve, by its nature, is an on/off type valve specifically designed for providing absolute, positive isolation.

Q3: What are the paramount considerations for selecting the optimal body material for an electric valve for water application?

A: The selection of the ideal body material for an **electric valve for water** is multi-faceted and critically depends on several factors: the specific chemical composition of the water (e.g., pH levels, chloride content, dissolved oxygen, presence of H2S), the operating temperature and pressure, and the potential presence of any abrasive particles or corrosive chemicals. Common high-performance materials include ductile iron for general water services, carbon steel for higher pressures, and various grades of stainless steel (304, 316, 316L, Duplex, Super Duplex) for enhanced corrosion resistance in aggressive or critical water applications. Our experienced engineers at HBYS can provide expert guidance to assist you in selecting the most appropriate and cost-effective material for your specific water conditions and operational requirements.

Q4: How does a high pressure electric valve ensure paramount safety in challenging environments?

A: A **high pressure electric valve** ensures paramount safety through a combination of meticulously engineered robust construction using high-strength, certified materials, precision manufacturing to withstand extreme internal and external pressures, and adherence to rigorous testing protocols (e.g., hydrostatic testing performed at 1.5 times the rated pressure, in compliance with ASME B16.34 and API standards). Electric actuation further enhances safety by enabling remote and precisely controlled operation, thereby significantly minimizing human exposure to potentially hazardous high-pressure lines or environments. For critical positive isolation applications, such as the F943CX Electric Blind Valve, its innovative design guarantees absolutely zero leakage, establishing an uncompromised physical safety barrier.

Q5: What are the typical industry standards and best practices for installing these valves?

A: The installation of an **electric valve for water** should strictly adhere to established industry best practices, relevant national and international standards (such as ASME B16.5 for pipe flanges and flanged fittings, or specific project piping specifications), and local safety regulations. Critical aspects include proper pipeline alignment, correct bolt tightening procedures (e.g., using torque wrenches and specified sequences), adequate support for large valves, and meticulous consideration for electric actuator mounting, wiring, and commissioning. HBYS Valves provides comprehensive, detailed installation manuals with every product and can offer specialized on-site installation guidance or supervision if required for complex projects, ensuring optimal performance and safety from day one.

Q6: How does the F943CX Electric Blind Valve offer advantages over a traditional manual spectacle blind?

A: A traditional manual spectacle blind requires laborious and time-consuming manual loosening of numerous bolts, physical rotation of the blind plate, and subsequent re-tightening of bolts. This process is highly labor-intensive, often requires specialized tools, and inherently poses significant safety risks, especially in large-diameter, high-temperature, or high-pressure lines. The F943CX Electric Blind Valve, with its advanced electric actuation, offers fully automated, remote, and significantly faster operation. It achieves the same absolute positive isolation but with unparalleled convenience, drastically reduced operational hazards, and minimal human intervention, making it a truly revolutionary and safe rapid electric valve for critical isolation purposes in modern industrial facilities.

Q7: What is your typical delivery lead time for custom electric valve for water solutions?

A: Delivery lead times for custom **electric valve for water** solutions, including specialized configurations of the F943CX Electric Blind Valve, vary significantly based on the complexity of the design, the availability of specialized raw materials, the current production schedules, and the order volume. For standard products, typical lead times might range from 4 to 8 weeks. However, for highly customized, large-diameter, or extensive project orders, lead times could range from 12 to 24 weeks. We are committed to providing clear, transparent, and accurate timelines at the quotation stage and maintain continuous communication with our clients, providing regular updates on production progress to ensure predictable project planning and timely delivery.

Warranty and Customer Support

HBYS Valves offers a comprehensive and industry-leading warranty period, typically extending for 12-24 months from the date of installation or 18-30 months from the date of original shipment, whichever event occurs first. This robust warranty strictly covers any manufacturing defects and material failures that may occur under normal operating conditions and adherence to recommended usage. Our dedicated and highly responsive customer support team is readily available to provide expert assistance with all technical queries, efficient troubleshooting, timely provision of genuine spare parts, and comprehensive field service support, thereby ensuring minimal downtime for your critical operations and maximizing your return on investment.

For any inquiries, technical support, or to discuss your specific valve requirements, please do not hesitate to visit our official website at www.hbysvalves.com or directly contact our sales and service departments. Our unwavering commitment is to ensure your long-term satisfaction and guarantee the continuous, reliable, and optimal operation of your HBYS electric valve for water solutions.

References and Further Reading

To deepen your understanding of the intricate world of fluid control, valve technologies, and smart water management, we highly recommend exploring the following authoritative industry sources and academic publications:

-

Global Market Research:

"Smart Water Management Market Size, Share & Trends Analysis Report By Component (Hardware, Software, Services), By Application (Commercial & Industrial, Residential), By Region, And Segment Forecasts, 2023 - 2030." This comprehensive report by Grand View Research provides invaluable insights into the burgeoning smart water management sector, highlighting growth drivers and technological advancements. Available at: https://www.grandviewresearch.com/industry-analysis/smart-water-management-market

-

International Industry Standards:

"ISO 9001:2015 Quality management systems – Requirements." Published by the International Organization for Standardization (ISO), this standard outlines the criteria for a quality management system, underscoring the importance of consistent quality in manufacturing. Available at: https://www.iso.org/standard/66737.html

"API Standards for Valves." The American Petroleum Institute (API) provides critical standards that ensure the safety, reliability, and interchangeability of equipment used in the oil and gas industry, many of which are cross-applicable to demanding water applications. Available at: https://www.api.org/products-and-services/standards/important-information/valve-standards

"ASME Boiler and Pressure Vessel Code (BPVC)." The American Society of Mechanical Engineers (ASME) publishes codes and standards for mechanical engineering, crucial for the design and construction of pressure-retaining components like valves. Available at: https://www.asme.org/codes-standards/publications/bpvc

-

Leading Industry Publications and Professional Associations:

Valves Magazine: A prominent industry publication offering up-to-date news, emerging trends, and in-depth technical articles pertinent to the global valve industry, including advancements in electric actuation. https://www.valvesmagazine.com/

American Water Works Association (AWWA): A comprehensive resource providing invaluable research, established standards, and essential professional development opportunities for water professionals and utilities globally, focusing on safe and sustainable water. https://www.awwa.org/

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025