Jan . 13, 2025 14:02

Back to list

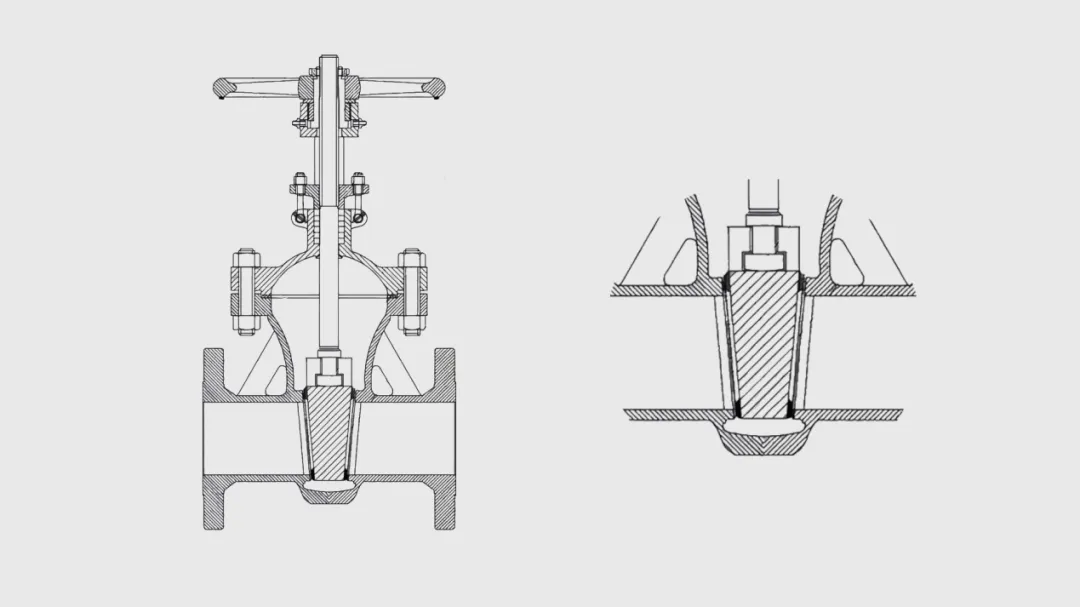

ANSI CAST STEEL MANUAL GATE VALVE WITH WATER

Navigating the landscape of industrial equipment demands an understanding of quality and durability, especially when choosing components like cast iron globe valves. These highly prized components serve as essential regulation devices in various pipeline systems, allowing precise control over fluid flow in industries ranging from oil and gas to water treatment facilities. Recognized for their robustness and versatility, cast iron globe valves offer a competitive advantage in energy efficiency and operational safety.

Incorporating an intuitive design process also contributes to the valve's functionality and reliability. Modern cast iron globe valves incorporate advanced sealing technologies, such as elastomer and metal-to-metal seal configurations, which enhance their suitability for isolation and accurate flow regulation. Such technological advancements in construction empower industries to achieve high precision in flow management, thereby bolstering operational trust over time. Moreover, leading-edge manufacturers often infuse the valve’s development process with innovative testing methodologies. Rigorous testing simulating real-world conditions ensures that every cast iron globe valve output can withstand the dynamic challenges encountered in diverse operation settings, further increasing the product's credibility. These valves not only exceed performance expectations but also enhance safety protocols, delivering peace of mind to operators and engineers alike. When selecting a cast iron globe valve, it's imperative to match the software with specific flow requirements. Consulting with engineers or valve specialists aids in choosing a configuration that aligns with the pipeline’s functional demands, ensuring optimal performance. This collaboration between knowledge and requirement underscores the essence of expertise, helping industries make informed decisions. In conclusion, the significance of cast iron globe valves cannot be overstated within the industrial sector. These devices epitomize durability, trustworthiness, and efficiency. Their use translates into operational excellence, aligning with a commitment to sustainable and cost-effective industrial processes. Entrusting your system with cast iron globe valves from elite manufacturers positions you at the forefront of innovation and reliability, embodying the core principles of experience, expertise, authoritativeness, and trustworthiness.

Incorporating an intuitive design process also contributes to the valve's functionality and reliability. Modern cast iron globe valves incorporate advanced sealing technologies, such as elastomer and metal-to-metal seal configurations, which enhance their suitability for isolation and accurate flow regulation. Such technological advancements in construction empower industries to achieve high precision in flow management, thereby bolstering operational trust over time. Moreover, leading-edge manufacturers often infuse the valve’s development process with innovative testing methodologies. Rigorous testing simulating real-world conditions ensures that every cast iron globe valve output can withstand the dynamic challenges encountered in diverse operation settings, further increasing the product's credibility. These valves not only exceed performance expectations but also enhance safety protocols, delivering peace of mind to operators and engineers alike. When selecting a cast iron globe valve, it's imperative to match the software with specific flow requirements. Consulting with engineers or valve specialists aids in choosing a configuration that aligns with the pipeline’s functional demands, ensuring optimal performance. This collaboration between knowledge and requirement underscores the essence of expertise, helping industries make informed decisions. In conclusion, the significance of cast iron globe valves cannot be overstated within the industrial sector. These devices epitomize durability, trustworthiness, and efficiency. Their use translates into operational excellence, aligning with a commitment to sustainable and cost-effective industrial processes. Entrusting your system with cast iron globe valves from elite manufacturers positions you at the forefront of innovation and reliability, embodying the core principles of experience, expertise, authoritativeness, and trustworthiness.

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025