Suppliers of Ring Joint Flanges for Reliable Sealing Solutions and Applications

Understanding Ring Joint Flanges and the Importance of Reliable Suppliers

In various industrial applications, flanges serve as crucial components in piping systems, ensuring the secure connection of pipes and equipment. Among the multitude of flange types available in the market, ring joint flanges distinguish themselves through their unique design and functionality. For engineers, procurement managers, and operators in industries such as oil and gas, chemical processing, and power generation, choosing the right supplier for ring joint flanges is a critical decision that can significantly impact the integrity and safety of operations.

What are Ring Joint Flanges?

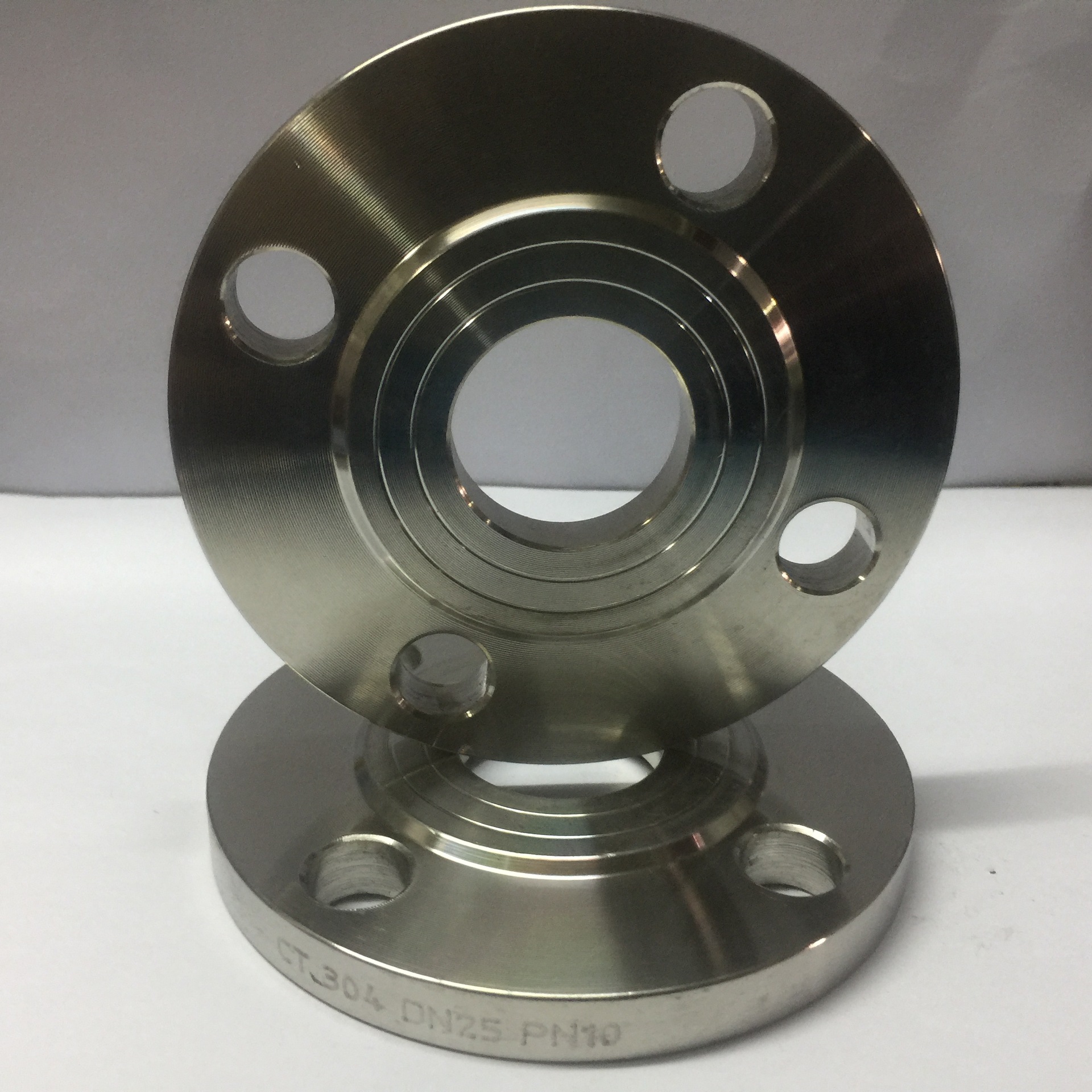

Ring joint flanges are specialized flange designs that utilize a metallic ring inserted into a groove on the flange face to create an effective seal when pressure is applied. This type of flange is particularly advantageous in high-pressure and high-temperature applications, where leakage is a critical concern. The design allows for a more uniform load distribution, resulting in enhanced sealing capabilities compared to traditional flat or raised face flanges.

The rings used in these flanges are typically made from materials like soft iron, stainless steel, or other alloys, enabling them to achieve a compressed state that forms an airtight seal. Common applications include oil drilling rigs, refineries, and chemical plants, where the challenge of maintaining a secure seal on pipelines is paramount.

The Role of Suppliers

The selection of a reliable supplier for ring joint flanges is vital for several reasons

1. Quality Assurance The integrity of flanges directly affects the performance and safety of the piping system. Suppliers must adhere to stringent quality control standards and obtain necessary certifications like ISO 9001. This ensures that flanges can withstand operational stresses without failure.

2. Material Specifications Different applications require specific materials to withstand various pressures, temperatures, and corrosive environments. A reputable supplier should offer a wide range of materials and possess the technical expertise to guide customers toward the most suitable choices for their unique applications.

3. Customization Every project is different, and often, standard flange sizes may not meet specific engineering requirements. Established suppliers can provide customization options, such as unique dimensions, ring designs, and material properties, ensuring compatibility and optimal performance.

ring joint flanges suppliers

4. Timely Delivery In industrial settings, delays in procurement can lead to significant financial losses and project setbacks. Reliable suppliers understand the importance of timely deliveries and often maintain extensive inventories or efficient manufacturing processes to meet urgent demands.

5. Technical Support and Consultation The complexity of working with ring joint flanges necessitates a supplier with robust technical support. Suppliers that offer consulting services help customers choose the right flange sizes, gasket types, and sealing methods, significantly reducing the risk of installation errors and subsequent failures.

Choosing the Right Supplier

When looking for ring joint flange suppliers, several factors should be considered

- Reputation and Experience Review customer feedback and case studies to gauge the supplier’s track record in the industry. An experienced supplier is likely to have encountered various challenges and can provide insights based on practical experiences.

- Certifications and Standards Compliance Ensure that the supplier complies with all relevant industry regulations and standards, as this is indicative of their commitment to quality and safety.

- Range of Products A wide array of options can indicate a supplier's expertise and ability to cater to diverse industry needs.

- After-Sales Support Consider suppliers that provide after-sales support, which can include installation guidance or assistance with troubleshooting post-installation issues.

Conclusion

In conclusion, ring joint flanges represent a critical component in high-pressure piping systems across various industries. The importance of selecting a reliable supplier cannot be overstated. By prioritizing quality, material selection, customization, timely delivery, and robust technical support, businesses can ensure the optimal performance and safety of their operations. Investing time in choosing the right supplier ultimately pays dividends in the form of reduced downtime, enhanced operational efficiency, and greater peace of mind.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025