មករា . 13, 2025 11:01

Back to list

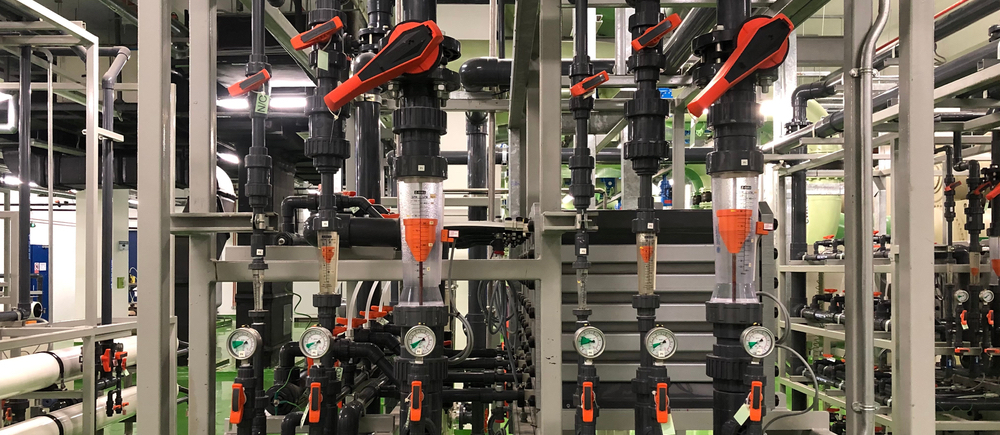

flange butterfly valve

Flange butterfly valves represent a significant component in various industrial applications, known for their efficacy in controlling fluid flow with precision. These valves, characterized by their circular disc which rotates to modulate flow, blend the simplicity of design with optimal functionality, creating a pivotal role in numerous engineering and manufacturing processes.

Trustworthiness in the context of flange butterfly valves is further established through proven field performance and positive customer testimonials. Companies provide detailed documentation, including technical datasheets, installation guides, and maintenance manuals, which help end-users in the proper deployment and upkeep of these valves. Additionally, many manufacturers offer warranties and after-sales support, ensuring continued service throughout the lifecycle of the product. One of the key real-world experiences enhancing the adoption of flange butterfly valves is their role in increasing efficiency and reducing operational costs. For instance, in water treatment facilities, these valves offer rapid switching capabilities and minimal pressure drop, enhancing the overall process speed and reducing energy consumption. In contrast, their corrosion-resistant properties in chemical plants prevent contamination, ensuring the purity and quality of the final product. Moreover, the evolution of technology has integrated smart systems with flange butterfly valves, allowing remote monitoring and control. This advancement not only optimizes performance but also enables predictive maintenance, thereby preventing downtime and minimizing repair costs. These smart systems collect and analyze data to inform decision-making processes, ensuring that the valve’s performance aligns with the intended application requirements. In conclusion, flange butterfly valves continue to be an essential component across a myriad of industries, thanks to their flexible connectivity, robust design, and adaptability to various operational demands. By understanding the intrinsic details, technological enhancements, and industry standards governing their use, stakeholders can leverage these valves to achieve superior outcomes, underscoring their position as a trusted solution in fluid control applications. Emphasizing expertise, authoritativeness, and trustworthiness in the selection and application of flange butterfly valves will ensure operational success and continuity.

Trustworthiness in the context of flange butterfly valves is further established through proven field performance and positive customer testimonials. Companies provide detailed documentation, including technical datasheets, installation guides, and maintenance manuals, which help end-users in the proper deployment and upkeep of these valves. Additionally, many manufacturers offer warranties and after-sales support, ensuring continued service throughout the lifecycle of the product. One of the key real-world experiences enhancing the adoption of flange butterfly valves is their role in increasing efficiency and reducing operational costs. For instance, in water treatment facilities, these valves offer rapid switching capabilities and minimal pressure drop, enhancing the overall process speed and reducing energy consumption. In contrast, their corrosion-resistant properties in chemical plants prevent contamination, ensuring the purity and quality of the final product. Moreover, the evolution of technology has integrated smart systems with flange butterfly valves, allowing remote monitoring and control. This advancement not only optimizes performance but also enables predictive maintenance, thereby preventing downtime and minimizing repair costs. These smart systems collect and analyze data to inform decision-making processes, ensuring that the valve’s performance aligns with the intended application requirements. In conclusion, flange butterfly valves continue to be an essential component across a myriad of industries, thanks to their flexible connectivity, robust design, and adaptability to various operational demands. By understanding the intrinsic details, technological enhancements, and industry standards governing their use, stakeholders can leverage these valves to achieve superior outcomes, underscoring their position as a trusted solution in fluid control applications. Emphasizing expertise, authoritativeness, and trustworthiness in the selection and application of flange butterfly valves will ensure operational success and continuity.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025