មករា . 17, 2025 03:22

Back to list

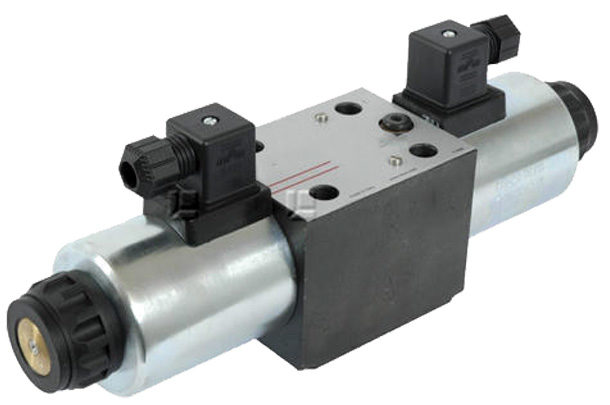

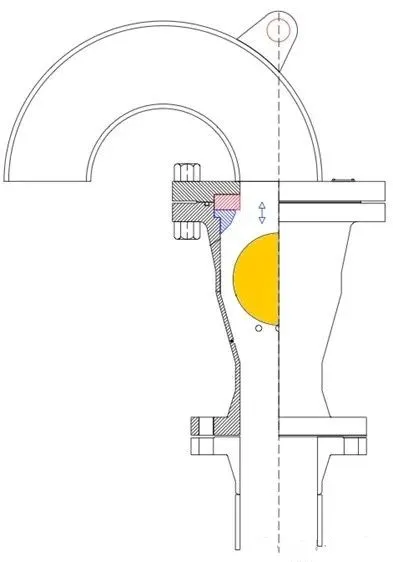

gate valve pneumatic

Fresh from the realms of cutting-edge engineering, pneumatic gate valves offer transformative solutions for industries demanding precise fluid control. As a leading-edge product in the realm of flow management, these valves are a testament to innovations in mechanical engineering and automation technologies. Delving into the nuances of pneumatic gate valves reveals their unmatched proficiency in industrial applications, encouraging industry experts to consider their benefits for optimized performance and reliability.

Expertise in selecting the right pneumatic gate valve involves understanding specific operational demands and environmental factors. Industry experts consider factors such as fluid type, pressure requirements, and ambient environmental conditions to recommend valves that achieve the best results. Collaborating with manufacturers who provide comprehensive support and customization options can lead to the development of bespoke solutions tailored to unique industry needs. In terms of authority and trustworthiness, pneumatic gate valves are frequently subjected to rigorous testing and compliance checks with industry standards. Certifications and adherence to international standards such as ISO and API reassure operators of their safety and efficiency. These components are meticulously engineered and tested to guarantee consistent performance, providing reassurance to even the most stringent safety audits. Furthermore, comprehensive maintenance and support programs offered by leading manufacturers enhance the operational lifespan of pneumatic gate valves. These programs encompass regular inspections, spare parts availability, and operational advice to mitigate downtimes and repairs. Partnering with reputable providers who offer these services further underscores the trustworthiness of pneumatic gate valves as a reliable investment. In conclusion, pneumatic gate valves represent a fusion of experience, expertise, and innovation in fluid control systems. Their advanced features, including durability, precision, and automation capabilities, make them an invaluable asset to industries seeking to enhance their operational efficiencies. Expert selection and adherence to industry standards elevate these valves as a trusted solution, endorsed by both engineers and operators across the globe. As industries continue to evolve, embracing such advanced technologies will foster sustainability and productivity for years to come.

Expertise in selecting the right pneumatic gate valve involves understanding specific operational demands and environmental factors. Industry experts consider factors such as fluid type, pressure requirements, and ambient environmental conditions to recommend valves that achieve the best results. Collaborating with manufacturers who provide comprehensive support and customization options can lead to the development of bespoke solutions tailored to unique industry needs. In terms of authority and trustworthiness, pneumatic gate valves are frequently subjected to rigorous testing and compliance checks with industry standards. Certifications and adherence to international standards such as ISO and API reassure operators of their safety and efficiency. These components are meticulously engineered and tested to guarantee consistent performance, providing reassurance to even the most stringent safety audits. Furthermore, comprehensive maintenance and support programs offered by leading manufacturers enhance the operational lifespan of pneumatic gate valves. These programs encompass regular inspections, spare parts availability, and operational advice to mitigate downtimes and repairs. Partnering with reputable providers who offer these services further underscores the trustworthiness of pneumatic gate valves as a reliable investment. In conclusion, pneumatic gate valves represent a fusion of experience, expertise, and innovation in fluid control systems. Their advanced features, including durability, precision, and automation capabilities, make them an invaluable asset to industries seeking to enhance their operational efficiencies. Expert selection and adherence to industry standards elevate these valves as a trusted solution, endorsed by both engineers and operators across the globe. As industries continue to evolve, embracing such advanced technologies will foster sustainability and productivity for years to come.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025