Reliable Rubber Expansion Joints for Pipe Systems

Navigating the Evolving Landscape of Industrial Piping Systems

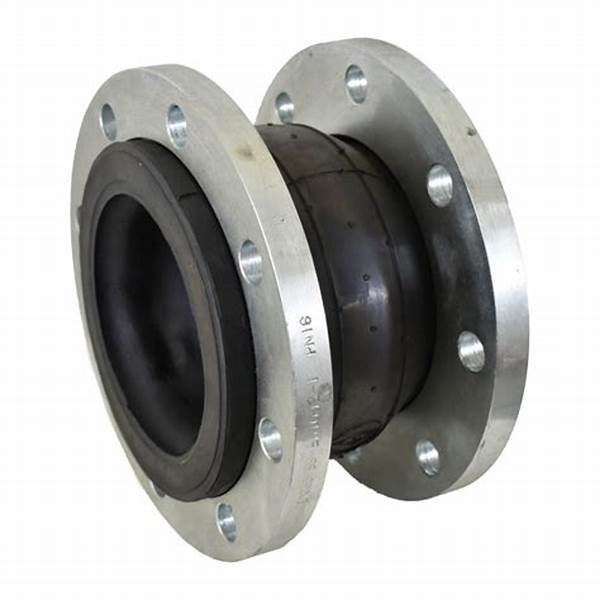

In the intricate world of industrial fluid transfer, managing thermal expansion, vibration, and pipe misalignment is critical for operational integrity and longevity. The demand for resilient, high-performance components has driven continuous innovation in solutions designed to absorb system stresses. Among these, rubber joints stand out as indispensable elements, providing unparalleled flexibility and durability. As industries globally push for greater efficiency and reliability, the evolution of these components, including advanced rubber expansion joint designs, is central to modern infrastructure development. This segment explores the prevailing industry trends and the pivotal role these flexible connectors play in diverse applications, from critical process piping to heavy machinery.

The market for rubber expansion joint solutions is experiencing robust growth, fueled by increasing investment in infrastructure, chemical processing, and power generation sectors. Current trends indicate a significant shift towards materials offering enhanced chemical resistance and higher temperature thresholds, alongside designs that facilitate easier installation and maintenance. Furthermore, the emphasis on sustainability and energy efficiency is prompting manufacturers to develop products that minimize pressure drop and improve flow characteristics. This strategic evolution ensures that these vital components can meet the demanding operational parameters of contemporary industrial environments, safeguarding against system failure and reducing downtime.

Understanding the Anatomy and Production of Advanced Rubber Joints

A rubber expansion joint for pipe is engineered to absorb axial compression, extension, lateral deflection, and angular rotation in piping systems, effectively mitigating stress caused by thermal changes, pump vibrations, or structural settlement. Typically, these joints consist of an elastomeric body, reinforced with fabric or metallic wire, and flanged or threaded end connections. The JGD41-10/16 Rubber Curved Joints, for instance, are meticulously designed with a curved profile, allowing for superior flexibility in confined spaces or specific directional changes, optimizing system layout while maintaining performance integrity.

Manufacturing Precision: From Raw Material to Finished Product

The manufacturing process for high-quality general rubber expansion joints is a multi-stage, precision-driven endeavor. It begins with the selection of premium elastomeric compounds—such as EPDM, NBR, or Neoprene—chosen for their specific chemical resistance, temperature range, and mechanical properties. These materials undergo calendering and cutting into precise patterns, which are then meticulously hand-wrapped around a mandrel. Reinforcement layers, typically high-strength nylon or steel wire, are incorporated to provide pressure resistance and structural integrity.

Following the assembly, the semi-finished joint undergoes vulcanization in specialized molds, a process where the rubber is cured under heat and pressure, transforming it into its final, resilient form. This crucial step ensures the material achieves optimal elasticity and strength. Post-vulcanization, each rubber expansion joint is subjected to rigorous quality control, including hydrostatic pressure tests to verify burst strength, vacuum tests for integrity, and dimensional checks against international standards such as ISO 9001:2015 and ANSI B16.5 for flange drilling patterns. Our JGD41-10/16 Rubber Curved Joints are engineered for a minimum service life of 5-10 years under specified conditions, depending on application severity and maintenance practices, demonstrating their robust design and manufacturing precision.

Key Technical Parameters and Performance Metrics

Selecting the appropriate rubber joints requires a thorough understanding of their technical specifications, which dictate their suitability for specific operational environments. Key parameters include nominal diameter, maximum operating pressure, temperature range, axial compression/extension, lateral deflection, and angular rotation capabilities. For instance, the JGD41-10/16 Rubber Curved Joints are specifically designed to accommodate significant movements in pipe systems where space constraints or complex layouts are present, offering a pressure rating typically up to 1.6 MPa and temperatures ranging from -15°C to 115°C, depending on the rubber compound used.

Typical Rubber Expansion Joint Parameters

| Parameter | Typical Range/Value | Significance |

|---|---|---|

| Nominal Diameter (DN) | DN32 - DN3000 | Matches pipe size for seamless integration. |

| Working Pressure | 0.6 MPa - 2.5 MPa | Determines suitability for low to high-pressure systems. |

| Operating Temperature | -20°C to +200°C (material dependent) | Crucial for material selection (e.g., EPDM for high temp, NBR for oil). |

| Axial Movement | ±10 mm to ±50 mm | Accommodates thermal expansion/contraction along pipe axis. |

| Lateral Movement | ±10 mm to ±30 mm | Handles pipe misalignment and transverse displacement. |

| Angular Movement | ±5° to ±15° | Compensates for angular pipe deflection. |

| Flange Standard | ANSI B16.5, DIN, JIS, EN1092-1 | Ensures compatibility with existing piping flanges globally. |

The performance of rubber joints is also significantly influenced by their design. Single-sphere, twin-sphere, or arched designs each offer distinct advantages in terms of movement absorption and pressure containment. The selection of materials, including the inner tube, reinforcing plies, cover, and metal flanges, is paramount. Advanced elastomers provide excellent chemical resistance to acids, alkalis, oils, and various industrial fluids, making these joints ideal for applications demanding rigorous material compatibility and long-term performance under harsh conditions.

Versatile Applications and Strategic Advantages

The versatility of rubber joints makes them indispensable across a multitude of industrial sectors. They are extensively used in petrochemical plants, protecting pipelines from thermal expansion and aggressive chemicals. In metallurgy, they absorb vibrations from heavy machinery like pumps and compressors, extending the lifespan of connected equipment. The water supply and drainage sector relies on them for managing pipeline settlement, seismic activity, and surges, ensuring uninterrupted flow and preventing leaks. Power generation facilities employ them to manage steam and cooling water lines, mitigating stress from high temperatures and pressures.

The strategic advantages of deploying high-quality rubber expansion joint for pipe solutions are multifaceted. They offer superior vibration absorption, significantly reducing noise and wear on pumps, chillers, and other vibrating equipment. Their elastomeric construction provides inherent corrosion resistance against various fluids, minimizing the need for frequent replacements compared to metal alternatives. Furthermore, by accommodating pipe misalignment and movement, they prevent stress concentrations, which can lead to fatigue failure in rigid piping systems. This proactive approach to pipe stress management translates into substantial energy savings by preventing leaks and maintaining optimal flow, alongside considerable cost reductions through extended equipment life and reduced maintenance. Our JGD41-10/16 Rubber Curved Joints are particularly advantageous in complex installations where their unique curvature simplifies pipe routing and enhances system flexibility.

Ensuring Quality: Certifications, Custom Solutions, and Customer Trust

In the B2B landscape, the authority and trustworthiness of a manufacturer are paramount. Our commitment to quality is underscored by rigorous adherence to international standards. Our manufacturing facilities operate under ISO 9001:2015 certified quality management systems, ensuring that every rubber expansion joint meets the highest benchmarks for design, production, and testing. Products are routinely tested for compliance with relevant industry standards such as ANSI, DIN, and JIS, guaranteeing compatibility and reliable performance globally. With over 20 years of expertise in valve and joint manufacturing, we have served a broad spectrum of industries, establishing long-term partnerships built on trust and consistent product excellence.

We understand that industrial applications often present unique challenges. Therefore, we specialize in providing tailored rubber expansion joint solutions, adapting designs, materials, and specifications to meet precise project requirements. Whether it's a specific chemical compatibility, higher pressure rating, or a unique physical dimension like our JGD41-10/16 Rubber Curved Joints, our engineering team collaborates closely with clients to deliver optimal solutions. This bespoke approach, combined with our robust quality assurance protocols and comprehensive after-sales support, solidifies our reputation as a trusted partner in critical infrastructure projects worldwide.

Frequently Asked Questions (FAQs) About Rubber Joints

- Q1: What is the typical lifespan of a rubber expansion joint?

- A1: The lifespan of a rubber expansion joint varies depending on factors such as operating temperature, pressure, media aggressiveness, and the frequency/magnitude of movements. Under normal operating conditions and proper installation, our joints are designed for a service life of 5 to 10 years, with some lasting even longer. Regular inspection and maintenance can extend their operational life.

- Q2: Can rubber joints handle corrosive fluids?

- A2: Yes, our rubber joints are manufactured with various elastomeric compounds (e.g., EPDM, NBR, Neoprene, Chlorobutyl) specifically chosen for their resistance to a wide range of corrosive chemicals, acids, alkalis, oils, and abrasive slurries. It is crucial to specify the fluid media during the selection process to ensure the correct material is used for optimal corrosion resistance.

- Q3: How does the JGD41-10/16 Rubber Curved Joints benefit complex piping systems?

- A3: The JGD41-10/16 Rubber Curved Joints are engineered with a specific curved geometry, offering superior flexibility and movement absorption in systems with limited space or requiring precise angular compensation. This design minimizes the need for additional elbows or complex pipe routing, streamlining installation and reducing overall system stress, particularly beneficial in compact plant layouts or marine applications.

- Q4: What is your typical delivery lead time and warranty policy?

- A4: Standard products typically have a delivery lead time of 4-6 weeks, while custom solutions may require additional time depending on complexity. We offer a comprehensive warranty, usually 12-18 months from shipment, covering manufacturing defects. Our dedicated customer support team is available to assist with any post-purchase inquiries, installation guidance, or technical support requirements.

Conclusion: Partnering for Reliable Industrial Solutions

The continuous innovation in rubber joints technology underscores their critical role in ensuring the integrity and efficiency of modern industrial piping systems. From mitigating seismic stresses in large infrastructure projects to absorbing pump vibrations in critical processing plants, these engineered components are vital for enhancing operational reliability and reducing long-term maintenance costs. Our commitment extends beyond providing high-quality products like the JGD41-10/16 Rubber Curved Joints; we aim to be a comprehensive solutions provider, offering expert consultation, custom design, and unwavering technical support to meet the unique demands of every project.

We pride ourselves on our rigorous testing protocols, adherence to global standards, and extensive experience, ensuring that every general rubber expansion joint delivered offers unmatched performance and durability. With transparent delivery schedules and robust warranty policies, we guarantee peace of mind for our B2B partners. Contact us to discuss your specific requirements and explore how our advanced rubber expansion joint for pipe solutions can optimize your industrial fluid handling systems.

References

- Fluid Sealing Association. (2018). Rubber Expansion Joint Technical Handbook.

- American National Standards Institute (ANSI). (2017). Piping Flanges and Flanged Fittings Standard (ASME B16.5).

- International Organization for Standardization (ISO). (2015). Quality management systems — Requirements (ISO 9001:2015).

- Rubber Manufacturers Association. (2019). Handbook of Rubber Compounds and Materials.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025