Feb . 06, 2025 01:42

Back to list

butterfly valve 4 inch

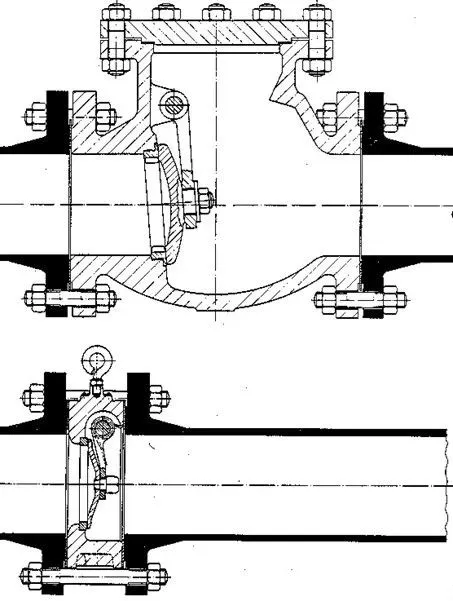

Understanding the 4-Inch Butterfly Valve A Comprehensive Guide for Industry Professionals

Operators must also consider the actuating mechanism of the butterfly valve. Manual, pneumatic, and electric actuators each offer specific advantages. Manual actuators give straightforward control in limited automation environments. In contrast, pneumatic actuators offer speed and reliability, making them ideal for frequent operations in automated setups. Electric actuators, on the other hand, provide precise modulating control, beneficial in processes requiring variable flow rates. The choice of actuator can significantly impact system performance and should be selected based on specific operational needs. A detailed understanding of the pressure and temperature ratings of a 4-inch butterfly valve is fundamental for ensuring reliable performance under varied conditions. The pressure rating denotes the maximum pressure the valve can withstand without leakage or damage, while the temperature rating specifies the range within which the valve material remains effective. For instance, valves used in chemical manufacturing require high-temperature thresholds, while those in water management systems may prioritize pressure endurance. Integrating a 4-inch butterfly valve into your system also requires diligence in maintenance to safeguard against unexpected failures and downtime. Regular inspection intervals must be established, with checks focused on the disc, seat, and actuating mechanism. Ensuring that the valve operates smoothly without unusual resistance or vibration is crucial, as these can be early indicators of wear. Industry leaders advise routine lubrication of moving parts to maintain mechanical integrity and extend operational life. Overall, the 4-inch butterfly valve is not merely a tool but a sophisticated component that complements myriad industrial applications. Its selection should involve scrutinizing material makeup, actuator type, and operational compatibility to maximize the value it delivers to a fluid system. With increasing industry demands and complex processing environments, professionals equipped with knowledge of butterfly valve intricacies will significantly enhance system efficiency, reduce operational costs, and ensure compliance with stringent environmental and safety regulations. As experts continue to innovate and refine butterfly valves, we can expect even greater advances in durability, efficiency, and technological integration. For industry professionals, staying abreast of these developments is not merely advantageous but essential for maintaining competitive edge and operational success.

Operators must also consider the actuating mechanism of the butterfly valve. Manual, pneumatic, and electric actuators each offer specific advantages. Manual actuators give straightforward control in limited automation environments. In contrast, pneumatic actuators offer speed and reliability, making them ideal for frequent operations in automated setups. Electric actuators, on the other hand, provide precise modulating control, beneficial in processes requiring variable flow rates. The choice of actuator can significantly impact system performance and should be selected based on specific operational needs. A detailed understanding of the pressure and temperature ratings of a 4-inch butterfly valve is fundamental for ensuring reliable performance under varied conditions. The pressure rating denotes the maximum pressure the valve can withstand without leakage or damage, while the temperature rating specifies the range within which the valve material remains effective. For instance, valves used in chemical manufacturing require high-temperature thresholds, while those in water management systems may prioritize pressure endurance. Integrating a 4-inch butterfly valve into your system also requires diligence in maintenance to safeguard against unexpected failures and downtime. Regular inspection intervals must be established, with checks focused on the disc, seat, and actuating mechanism. Ensuring that the valve operates smoothly without unusual resistance or vibration is crucial, as these can be early indicators of wear. Industry leaders advise routine lubrication of moving parts to maintain mechanical integrity and extend operational life. Overall, the 4-inch butterfly valve is not merely a tool but a sophisticated component that complements myriad industrial applications. Its selection should involve scrutinizing material makeup, actuator type, and operational compatibility to maximize the value it delivers to a fluid system. With increasing industry demands and complex processing environments, professionals equipped with knowledge of butterfly valve intricacies will significantly enhance system efficiency, reduce operational costs, and ensure compliance with stringent environmental and safety regulations. As experts continue to innovate and refine butterfly valves, we can expect even greater advances in durability, efficiency, and technological integration. For industry professionals, staying abreast of these developments is not merely advantageous but essential for maintaining competitive edge and operational success.

Next:

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025