Industry Trends in Gas Ball Valves Market

The gas ball valves market is experiencing robust growth, projected to reach a CAGR of 4.6% through 2028[1]. This surge is driven by the rapid expansion in the energy sector, stricter environmental safety regulations, and demand for advanced automation in pipeline control. With technological advances like anti-leakage seats, smart actuators, and ultra-low fugitive emissions, gas ball valves are now preferred for critical applications over conventional gate and globe valves.

- Major Drivers: LNG terminal expansion, pipeline upgrades, clean energy transitions

- Market Segments: Natural gas ball valve, oil and gas ball valve, industrial gas isolation, hydrogen projects

- Top Certifications: API 6D, ISO 15848-1, ANSI B16.34, CE, SIL3

Technical Parameters: Comparing Key Gas Ball Valve Types

Table 1: Technical Comparison of Gas Ball Valves (General Industry Data)| Type | Nominal Size (DN) | Working Pressure (PN / Class) | Body Material | Design Standard | Sealing Type | Fugitive Emission Rate | Service Life |

|---|---|---|---|---|---|---|---|

| Welded Gas Ball Valve | 15–800 mm | PN 16–420 (Class 150–2500) | ASTM A105, SS316 | API 6D, ISO 14313 | Soft/Metal | < 50 ppmv | 30,000 cycles |

| Flanged Natural Gas Ball Valve | 15–600 mm | PN 16–250 | WCB, F316 | ANSI, API | Soft | < 100 ppmv | 20,000 cycles |

| Oil & Gas Split Body Ball Valve | 50–1200 mm | PN 25–400 | LF2, CF8M | API 6D, EN 13709 | Soft/Metal | < 80 ppmv | 25,000 cycles |

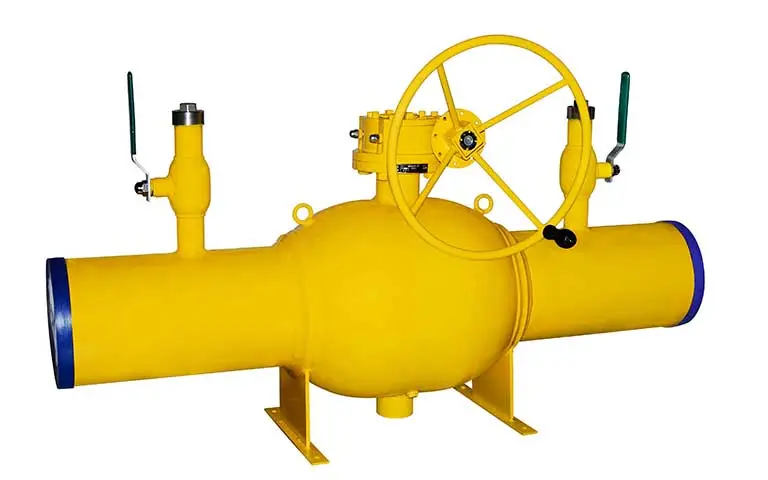

How DN 15-800mm Oil And Gas Welded Ball Valves Are Manufactured

Manufacture Summary: All raw materials for gas ball valves are sourced from ISO 9001-certified suppliers, forged with microstructure refinement, then precision CNC machined and welded under robotic control. Final assemblies undergo 100% hydrostatic and pneumatic leak-testing per API 598 & ANSI/FCI 70-2 with traceable testing certificates available.

- Material focus: ASTM A105/F304/F316L, Duplex Stainless, Inconel

- Design standards: API 6D, ISO 14313, ASME B16.34 Certified

- Inspection: Ultrasonic, PMI, X-ray, 3D metrology, seat leakage (≤50 ppmv)

- Life expectancy: >30,000 full-open/close cycles

Main Technical Specifications of DN 15-800mm Oil And Gas Welded Ball Valve

- Size Range: DN 15–800mm

- Pressure Classes: PN16 to PN420 (Class 150–2500)

- Temp. Range: -46°C to +425°C (cryogenic to superheated)

- End Connections: Fully welded, butt-weld, RTJ flange, PE tail

- Material: ASTM A105, F304/F316, Duplex steel, Inconel

- Sealing: PTFE, Devlon, Metal, Fire-safe certified per API 607

- Automation: Manual, Gear, Pneumatic, Electric, Hydraulic

- Compliance: API 6D, ISO 15848, EN 161, CE, SIL3

Technical Advantages of Modern Gas Ball Valves

- Bubble-tight seal: Advanced seat design ensures zero leakage (<50 ppmv tested) even under fluctuating pressure or temperature.

- Resistance to corrosion: NACE MR0175/ISO 15156 compliant for sour (H₂S) service; corrosion-resistant overlays on seat/lip for aggressive media.

- Maintenance-friendly: Top-entry and seat-injectable types support in-line maintenance—reducing planned plant downtime.

- Fire-safe & anti-static: Metal-to-metal or graphite seals, certified per API 607/6FA, with built-in antistatic device.

- Low torque operation: Precisely machined ball/stem system, trunnion-mount for large sizes, minimizes actuator sizing, lowers lifetime OPEX.

- Long life: Quarter-turn operation and robust design enables 30,000+ cycles in operation; field data confirms longevity & reliability.

Manufacturer Comparison: Leading Gas Ball Valves Suppliers

| Manufacturer | Main Product | Size Range | Key Certifications | Lead Time (weeks) | Warranty | Noted Projects |

|---|---|---|---|---|---|---|

| HBYS Valves China | DN 15-800mm Oil & Gas Welded Ball Valve | 15–800 mm | API 6D, ISO 9001, CE | 4–8 | 2 years | Sinopec, CNPC, ENEOS |

| Parker Velan | Trunnion Ball Valve, Floating Ball Valve | 20–1400 mm | API, ISO, SIL3 | 10–20 | 2 years | Pemex, Shell, BP |

| Habonim | Cryogenic Gas Ball Valve | 8–600 mm | ISO, Fire-Safe, CE | 8–14 | 1 year | Linde, Air Liquide |

| Emerson (Fisher) | Flanged Ball Valve, Welded Ball Valve | 15–1200 mm | API, PED, ATEX | 8–16 | 2 years | Aramco, ExxonMobil |

How does HBYS stand out? HBYS Valves offers customizable welding, ultra-short lead time, advanced traceability (RFID/QR), and full lifecycle management – all supported by multi-lingual, 24hr response customer support.

Custom Solutions for Specialized Requirements

- Material Options: Low-temp carbon steel (impact tested to –46°C), duplex, super duplex for offshore or sour applications.

- Connection Customization: Butt weld, RTJ, socket weld, or special PE ends for pipeline tie-ins.

- Automation: Smart positioners (with remote SCADA), SIL-rated electric/ pneumatic actuators, fail-safe devices, solar power options for remote sites.

- Testing & Docs: PED, API 6D, CE, RoHS, Fire Safe, NDT, EN10204-3.2 certification dossiers provided as per project requirement.

- Surface Treatment: Epoxy-polyurethane paint, high-build HEMPEL, FBE/3LPE external anticorrosion, cryogenic cleaning.

For integrated solutions, gas ball valves can be supplied as turnkey skids—fully assembled, FAT-tested, and shipped direct-to-site to streamline end-user installation.

Application Case Studies

1. Natural Gas Transmission Pipeline

Spec: 36” DN 900, Fully Welded, A105+ENP, Class 600, SCADA ready

Result: Zero leak in 36 months, confirmed via monthly in-line ultrasonic emission test. Achieved 12% OPEX reduction versus previous supplier.

2. Oil Refinery Turnaround

Custom-engineered oil and gas ball valve batches supplied for high-sulfur, high-pressure streams. All valves supplied with API 607 fire-safe certificate & fugitive emission data--no shutdowns due to valve maintenance in the past 4 years.

3. Petrochemical Plant (Cryogenic Unit)

Natural gas ball valves of DN 50–200mm have been installed on LNG vaporization skids, tested for –196°C, ensuring seat integrity via helium leak testing (

4. District Heating/Water Projects

End-users in Europe have deployed hundreds of large-diameter fully welded gas ball valves—valued for compact footprint, buried/underground install suitability, and zero water ingress risk compared to conventional gland-packed valves.

Product Feedback & Customer Experience

- "All gas ball valves received from HBYS continue to operate flawlessly after 3 years—minimal seat wear and no visible corrosion." (Gas utility engineer, EU customer)

- "Document control and tagging were perfect for our LNG project, with full traceability back to code-relief certificates." (Oil & Gas EPC, Middle East)

- "Switchover to oil and gas ball valve with low-torque actuator cut our power use by 10% on compressor lines." (Natural gas pipeline operator)

FAQ: Gas Ball Valves Expert FAQ

Order, Delivery & Assurance

- Lead time: 4–8 weeks standard; expedited options available

- Shipping: Global by sea, air, DAP/DDU/FCA, incoterms as required

- QA/Certification: Full EN10204, PED, API 6D, CE delivered per valve

- Warranty: 24 months from installation or 30 months from delivery

- Support: Advanced troubleshooting, documentation management, spares

- Aftersales: 24/7 technical support and remote diagnostics portal

Conclusion: Why Choose Gas Ball Valves from HBYS?

As shown throughout this analysis, modern gas ball valves equipped with globally certified features and optimized for operational efficiency are critical for safe, reliable, and cost-effective pipeline management. The DN 15-800mm Oil And Gas Welded Ball Valve leverages best-in-class metallurgy, tested manufacturing, and expert support. With proven deployments in global energy, petrochemical, water, and industrial projects, they help operators ensure compliance, minimize downtime, and optimize life cycle value.

For further information on trends or technical standards, refer to:

- Valve World: Gas Ball Valve Market Report

- American Petroleum Institute (API) Standards Center

- ScienceDirect: Advances in Industrial Valve Technologies

- Piping Engineering World – Valve Applications