Feb . 04, 2025 01:15

Back to list

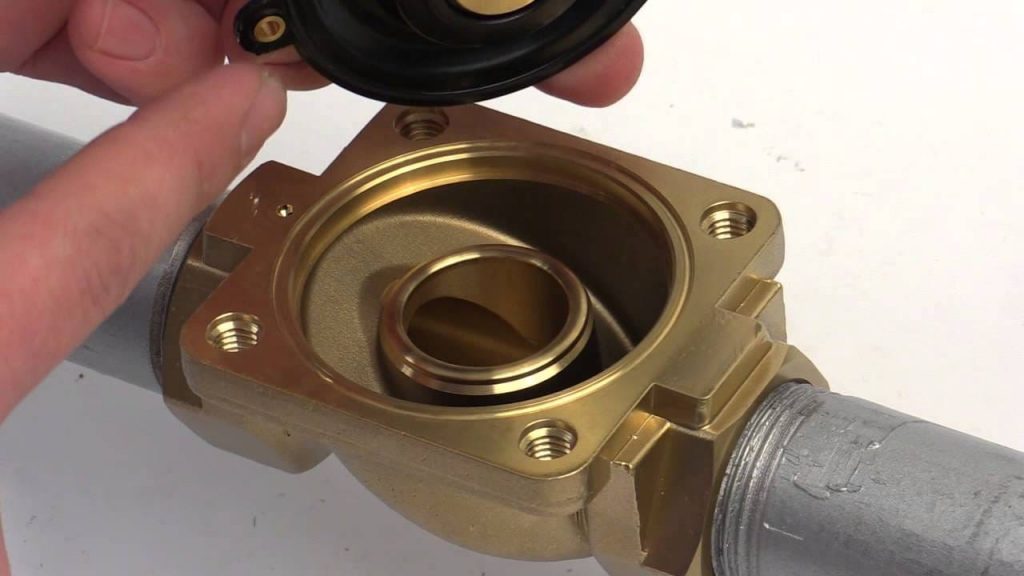

high temp ball valves

In the dynamic field of industrial applications, high temperature ball valves play a pivotal role, ensuring the safe and efficient control of fluid flow under severe temperature conditions. These specialized valves are engineered to withstand extreme temperatures, offering an unparalleled blend of durability, reliability, and precision which make them indispensable in various industries such as oil and gas, petrochemicals, and power generation.

One of the significant advantages of using high temperature ball valves is their adaptability. These valves are available in a range of sizes and pressure ratings, enabling customization for a wide array of applications. Whether it’s for modulating pressure in a steam-based energy plant or handling corrosive chemicals in a refinery, high temperature ball valves can be tailored to meet specific operational needs. Professionals in industries reliant on high temperature processes are increasingly turning to these specialized valves due to their reliability. Their sturdy construction and ability to maintain performance stability under extreme conditions make them a trusted choice among engineers and maintenance personnel alike. This reliability translates into reduced downtime, lower maintenance costs, and improved safety, which are critical considerations in high-stakes industrial environments. The authoritative presence that high temperature ball valves hold in industrial applications is reinforced by the rigorous standards they are held to. Many of these valves conform to strict international safety standards, such as those set by the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO), which underscores their quality and dependability. Compliance with such standards is a testament to their engineering excellence and provides a layer of trust and assurance for operators and engineers. In conclusion, high temperature ball valves are an essential component of modern industrial operations. Their exceptional thermal resistance, operational efficiency, and adaptability make them a superior choice for controlling fluid flow under extreme conditions. As industries continue to evolve and the demand for high-performance components increases, these valves will undoubtedly remain at the forefront, setting the standard for quality and reliability. Investing in high temperature ball valves not only enhances process efficiency but also ensures long-term operational success, cementing their status as a critical tool in industrial fluid management.

One of the significant advantages of using high temperature ball valves is their adaptability. These valves are available in a range of sizes and pressure ratings, enabling customization for a wide array of applications. Whether it’s for modulating pressure in a steam-based energy plant or handling corrosive chemicals in a refinery, high temperature ball valves can be tailored to meet specific operational needs. Professionals in industries reliant on high temperature processes are increasingly turning to these specialized valves due to their reliability. Their sturdy construction and ability to maintain performance stability under extreme conditions make them a trusted choice among engineers and maintenance personnel alike. This reliability translates into reduced downtime, lower maintenance costs, and improved safety, which are critical considerations in high-stakes industrial environments. The authoritative presence that high temperature ball valves hold in industrial applications is reinforced by the rigorous standards they are held to. Many of these valves conform to strict international safety standards, such as those set by the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO), which underscores their quality and dependability. Compliance with such standards is a testament to their engineering excellence and provides a layer of trust and assurance for operators and engineers. In conclusion, high temperature ball valves are an essential component of modern industrial operations. Their exceptional thermal resistance, operational efficiency, and adaptability make them a superior choice for controlling fluid flow under extreme conditions. As industries continue to evolve and the demand for high-performance components increases, these valves will undoubtedly remain at the forefront, setting the standard for quality and reliability. Investing in high temperature ball valves not only enhances process efficiency but also ensures long-term operational success, cementing their status as a critical tool in industrial fluid management.

Next:

Latest news

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025